الوصف

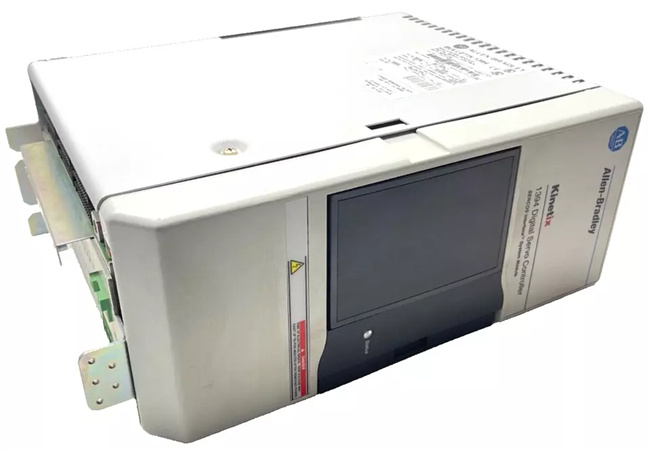

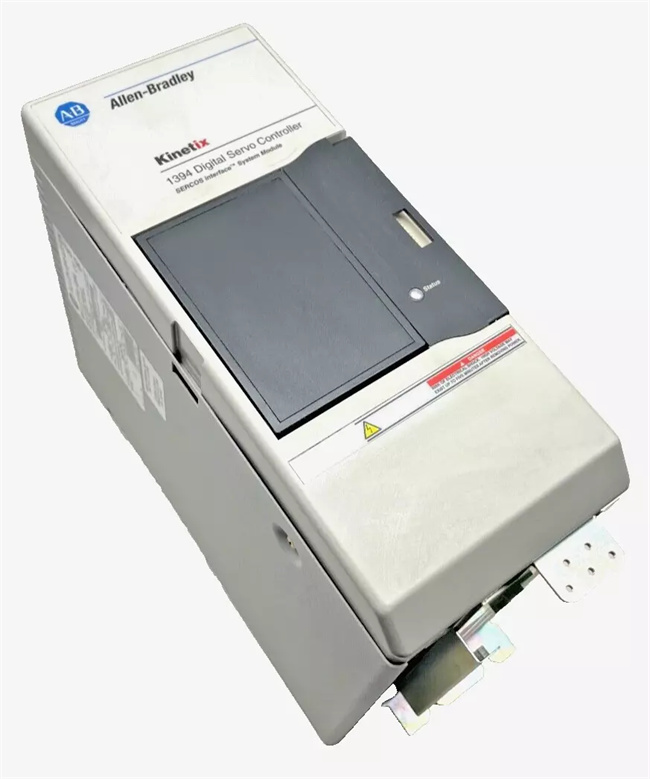

The A-B+1394C-SJT05-D is an industrial automation module developed by Allen-Bradley (a subsidiary of Rockwell Automation). It is part of the 1394 series, which focuses on motion control for high-performance applications, and is typically used in Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) environments. The 1394C-SJT05-D is a motion control module designed for high-precision applications where precise control of motors, drives, and other motion equipment is critical.

Product Name:

- A-B 1394C-SJT05-D Motion Control Module

Product Description:

The A-B 1394C-SJT05-D is a servo drive module designed for use in motion control systems. It is commonly used in DCS or PLC environments where it provides precise motor control, allowing operators to accurately control positioning, speed, and torque in industrial machinery. This module is part of Allen-Bradley’s 1394 SJT Series, which is specifically engineered for servo applications, offering exceptional performance in high-speed, high-torque applications such as robotics, CNC machines, automated material handling systems, and more.

The 1394C-SJT05-D is known for its compact design, reliable performance, and the ability to interface seamlessly with other Allen-Bradley components, making it a popular choice for integrating motion control into larger automation systems. It provides high-performance feedback, ease of setup, and advanced diagnostic capabilities, all while ensuring the safety and stability of motion systems.

Key Features:

- High-Precision Motion Control: Designed for servo applications, offering precise control over motor speed, position, and torque.

- Compatibility with Allen-Bradley Systems: Fully integrates with other Allen-Bradley controllers and PLC systems, such as ControlLogix and CompactLogix, providing a unified control architecture.

- Advanced Diagnostics: Built-in diagnostic features for monitoring performance and troubleshooting, ensuring high uptime and reliability.

- Compact Design: Ideal for installations where space is limited, without compromising on performance.

- Real-Time Motion Control: Capable of delivering real-time control for complex motion profiles, such as S-curve, trapezoidal, or linear.

- Flexible Communication: Supports Ethernet/IP and other industrial communication protocols for seamless data transfer between devices.

Product Parameters:

Here are the typical parameters for the A-B 1394C-SJT05-D module. Keep in mind that the exact configuration may vary depending on the application and system setup.

-

Input Power:

- AC Input Voltage: Typically supports a voltage range of 380-480V AC.

- Power Consumption: Varies depending on the motor load and configuration.

-

Motor Control Type:

- Servo Motor Control: Capable of driving AC or DC servo motors in high-performance motion control applications.

- Continuous Output Power: Varies depending on the model; typically rated for 5 kW or higher.

-

Feedback Type:

- Encoder Feedback: Typically supports resolver or encoder feedback for precise motor position control.

- Closed-Loop Control: For dynamic adjustments and accurate performance.

-

Communication:

- Ethernet/IP: For network communication with other automation devices, including controllers and other drives.

- RS-232/RS-485: For legacy device communication and remote control.

- Fieldbus: Possible support for DeviceNet and ControlNet depending on configuration.

-

Temperature Range:

- Operating Temperature: Typically between 0°C to 40°C (may vary depending on model).

- Storage Temperature: Typically between -20°C to 85°C.

-

Dimensions:

- The 1394C-SJT05-D is designed to be compact and fits within a standard industrial rack or enclosure.

- Dimensions: Can vary slightly based on configuration, but typically height: 200 mm, width: 150 mm, depth: 300 mm.

-

I/O Configuration:

- Depending on the exact configuration, the 1394C-SJT05-D module can handle various inputs and outputs for controlling motor speed, position, and other parameters, with options for digital and analog I/O.

- Digital I/O: For controlling motor start/stop, direction, etc.

- Analog I/O: For precise speed and position control.

Product Specifications:

Power Supply:

- Input Voltage: Supports 380V to 480V AC power supply for drive operation.

- Input Current: Varies depending on the system configuration and motor power requirements.

- Output Power: Typically rated for 5 kW or more, depending on motor load and drive specifications.

Motor Control:

- Motor Type Supported: Typically supports AC induction motors and permanent magnet motors.

- Control Method: Vector Control, Torque Control, or Velocity Control with real-time updates.

Feedback and Sensor Support:

- Encoder Feedback: Supports various encoder types for high-precision control, such as incremental and absolute encoders.

- Resolver Feedback: Typically supports resolver feedback for high-precision positioning.

- Closed-Loop System: Feedback loop for accurate motor control with real-time error correction.

Environmental Specifications:

- Operating Temperature: Typically 0°C to 40°C.

- Storage Temperature: Typically -20°C to 85°C.

- Humidity: Designed to function in non-condensing environments (typically up to 95% RH).

Safety Features:

- Safety Compliance: Designed to meet industrial safety standards (such as CE, UL, and CSA).

- Safe Torque Off (STO): To ensure safe operation and protection against sudden loss of power.

- Overcurrent, Overvoltage, and Overtemperature Protection: Built-in protections to avoid damage to the module.

Communication and Networking:

- Ethernet/IP: High-speed communication for real-time control and monitoring.

- RS-232/RS-485: For serial communication with other devices, controllers, and drives.

- Fieldbus Options: May include DeviceNet, ControlNet, or Profibus for flexibility in integrating with other devices.

Applications:

The A-B 1394C-SJT05-D is typically used in high-performance motion control applications across various industries, including:

- Automated Machinery: Control of high-speed, high-torque machines, such as robotic arms, CNC machines, and packaging machines.

- Material Handling Systems: Integration into automated conveyors, hoists, and lifts that require precise movement control.

- Motion Control Systems: Used in automated guided vehicles (AGVs), material processing machines, and other industrial automation equipment that requires high precision.

- Energy and Utilities: Control systems for motors in pumps, compressors, and fans within power plants, water treatment facilities, and other utility environments.

Conclusion:

The A-B 1394C-SJT05-D module is a high-performance motion control module tailored for precise motor control in demanding industrial applications. It offers real-time control, advanced diagnostics, and seamless integration with Allen-Bradley PLC and DCS systems. With support for various motor types, feedback mechanisms, and communication protocols, it is an ideal solution for industries requiring reliable, high-speed, and precise motion control.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922