الوصف

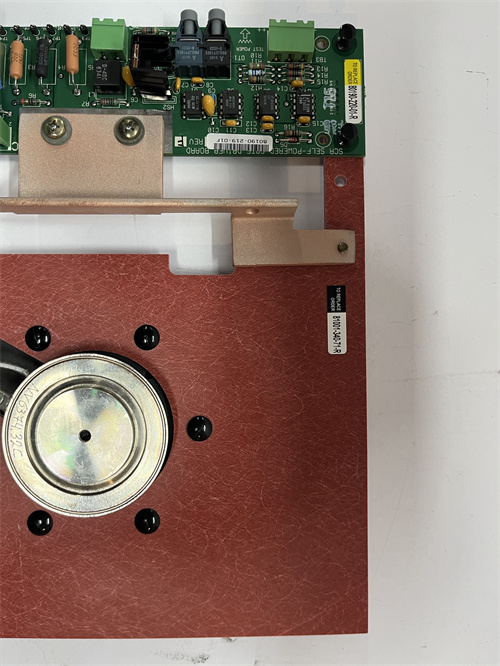

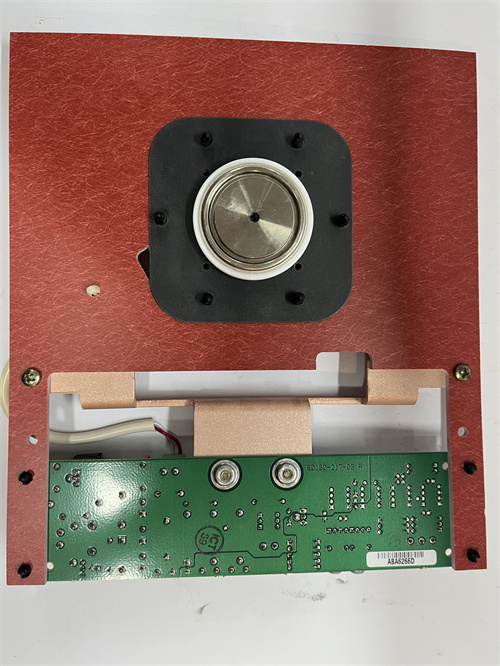

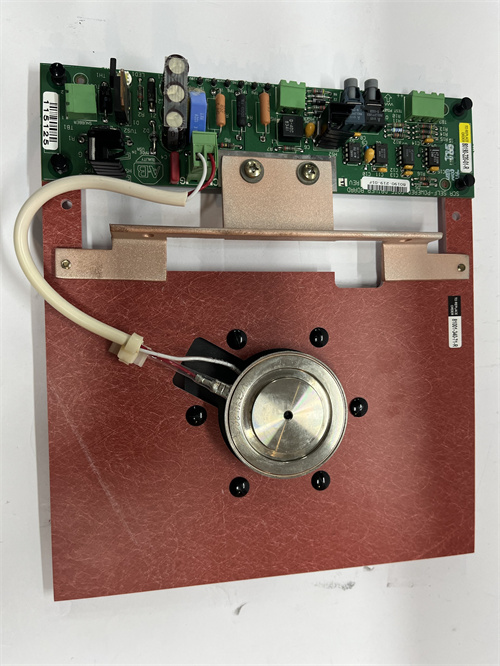

Product Name:

A-B+81001-340-71-R DCS PLC Module

Product Description:

The A-B+81001-340-71-R is a Distributed Control System (DCS) Programmable Logic Controller (PLC) module designed for industrial automation and control applications. Manufactured by Allen-Bradley (a subsidiary of Rockwell Automation), this module is a crucial component for complex automation systems requiring precise control, real-time data processing, and reliable communication.

The module is designed to be integrated into DCS architectures and is suited for a wide range of industries including manufacturing, energy, chemical processing, and water treatment. Known for its high performance, flexible configuration options, and easy integration with other Allen-Bradley products, it is a vital component in achieving efficient, automated control across industrial processes.

Product Parameters:

- Model Number: A-B+81001-340-71-R

- Type: DCS PLC Module

- Manufacturer: Allen-Bradley (Rockwell Automation)

- Series: Part of Allen-Bradley’s DCS product line (part of ControlLogix/Studio 5000 architecture)

- Operating Voltage: Typically 24V DC (may vary depending on configuration)

- Temperature Range: 0°C to 60°C (Standard Industrial Operating Range)

- Mounting: Typically rack-mounted or chassis-mounted in a larger control system

- Dimensions: Compact and modular design for flexible system integration

- Communication Protocols: Ethernet/IP, Modbus TCP/IP, Profibus, DeviceNet, ControlNet

- Redundancy: Optional redundancy configurations for power and communication (ensure system reliability and uptime)

- Program Memory: Flash memory for storing control programs, system configurations, and diagnostic data

- I/O Support: Configurable digital and analog I/O capabilities with expansion options

- Safety Standards: Typically complies with IEC, UL, CSA, and other regional safety standards

Product Specifications:

-

Input/Output (I/O) Capabilities:

- Digital I/O: Support for digital inputs and outputs for on/off control signals (e.g., switches, relays).

- Analog I/O: Support for analog inputs and outputs for continuous signals (e.g., temperature, pressure, flow measurements).

- Expansion: Modular design allows for easy expansion with additional I/O modules for larger, more complex systems.

- Signal Types: Compatible with a wide range of industrial field devices, including sensors, actuators, switches, and valves.

-

Real-Time Control:

- Real-time processing capabilities for fast and accurate decision-making, crucial for industrial control processes that require quick responses to changes in the environment or system inputs.

- Low latency and fast scan times for precise control of automation systems, enabling smooth operation in critical processes such as manufacturing, material handling, or energy management.

-

Processing Power:

- The module incorporates a high-performance processor that can handle complex control algorithms and data processing tasks.

- Built for high-speed processing, ensuring continuous monitoring and control of systems in real time.

- Features multitasking capabilities to handle multiple control loops simultaneously.

-

Communication Capabilities:

- Ethernet/IP and Modbus TCP/IP for network communication with other devices, such as HMIs, SCADA systems, and remote I/O.

- DeviceNet, ControlNet, Profibus for fieldbus communication, enabling seamless integration with a wide range of field devices (sensors, actuators, etc.).

- Redundant communications (optional) to ensure high availability and minimize communication failure risks in critical operations.

- Supports peer-to-peer communication between PLCs or between a PLC and other devices in a distributed control environment.

-

Diagnostic Features:

- Self-diagnostics for real-time monitoring of module health, with error codes and status indicators for troubleshooting and maintenance.

- Integrated diagnostic tools for system analysis and fault detection, helping identify issues before they affect operations.

- Ability to monitor I/O performance and status, ensuring the system operates within normal parameters and avoiding downtime.

-

Redundancy & Reliability:

- Supports redundant power supplies, ensuring continuity of operation even in the event of power supply failure.

- Communication redundancy features for seamless operation and communication integrity, particularly important in large-scale industrial systems with numerous connected devices.

- Built for high availability in mission-critical environments, ensuring minimal downtime and maximum reliability.

-

Programming & Integration:

- Programmed via Allen-Bradley’s Studio 5000 or RSLogix 5000 software, offering a user-friendly environment for creating and modifying control logic.

- Easy integration with other Allen-Bradley and third-party automation systems, offering a flexible approach to system design.

- Supports tag-based programming, where each I/O point, control routine, or device is assigned a unique tag, making it easier to manage and troubleshoot the system.

-

Environmental Durability:

- Designed to operate in harsh industrial environments with high levels of electromagnetic interference (EMI) and vibration.

- Rugged construction that meets global environmental standards for industrial equipment, including protection from dust, moisture, and corrosion.

- Compliant with IP20, IP65, or equivalent ratings (based on the specific model configuration).

-

System Integration:

- Fully compatible with other Allen-Bradley controllers, such as CompactLogix, ControlLogix, and FlexLogix, allowing for easy scaling and integration of larger automation systems.

- Supports HMI/SCADA systems for graphical visualization, monitoring, and control of system processes.

- Facilitates centralized or decentralized control architectures, allowing for flexibility in system design and configuration.

Applications:

The A-B+81001-340-71-R DCS PLC Module is designed for a wide range of industrial applications, including:

-

Power Generation & Distribution:

- Controls turbines, generators, circuit breakers, and substations to ensure continuous and efficient power production and distribution.

-

Chemical Processing & Petrochemical Plants:

- Monitors and controls reactors, mixers, pipelines, and distillation columns, maintaining the integrity of chemical processes and safety in hazardous environments.

-

Oil & Gas Production:

- Controls drilling rigs, offshore platforms, and refineries to optimize production processes, ensuring safe and efficient operations.

-

Water Treatment & Wastewater Management:

- Supervises filtration systems, pumps, and chemical dosing in water treatment plants, ensuring compliance with environmental regulations.

-

Manufacturing & Industrial Automation:

- Controls assembly lines, robotic arms, and material handling systems, optimizing production efficiency and reducing operational costs.

-

HVAC & Environmental Control Systems:

- Used for controlling large-scale HVAC systems in commercial and industrial buildings, optimizing energy usage and maintaining comfort.

Conclusion:

The A-B+81001-340-71-R DCS PLC Module is a highly reliable, scalable, and versatile automation solution for complex industrial control applications. With its robust communication capabilities, real-time processing power, and easy integration with other Allen-Bradley products, it provides an ideal solution for industries requiring precise control and continuous system monitoring.

If you need more specific details or have additional questions, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922