الوصف

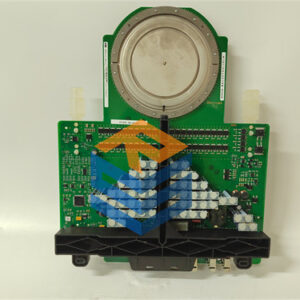

As an industrial automation expert, the ABB DSQC327A is immediately recognizable as a vital Combination I/O (Input/Output) Module primarily associated with ABB Industrial Robots and their controllers, such as the IRC5. The “DSQC” designation is standard for ABB robot control components. This module is a versatile piece of hardware, designed to handle both digital and analog signals, making it highly flexible for integrating various sensors and actuators into a robotic work cell.

Part One: Optimized SEO Titles

- ABB DSQC327A: Combination I/O Module for Robotics

- DSQC327A ABB: Robot Controller Analog/Digital I/O

- High-Performance I/O Module DSQC327A: ABB Robotics

- ABB DSQC327A: Integrating Sensors and Actuators in Robot Cells

- Buy DSQC327A: Genuine ABB Robot Spare Parts

- DSQC327A for Sale: Enhance ABB Robot System Connectivity

- ABB DSQC327A Module: Versatile I/O for Industrial Robots

- DSQC327A: Digital and Analog Control for ABB IRB Robots

- ABB DSQC327A: Streamlining Robot Automation

- DSQC327A Combi I/O: Essential for Robotic Workflows

Part Two: Brief Product Description

The ABB DSQC327A is a specialized Combination Input/Output (I/O) Module designed for seamless integration with ABB robot controllers, such as the IRC5. This versatile module combines both digital and analog I/O capabilities, typically offering a set number of digital inputs and outputs, alongside analog inputs and outputs. It serves as a crucial interface, allowing the robot controller to send commands to and receive feedback from various external devices like sensors, grippers, conveyors, and other machinery within the robotic work cell.

- Product Type: Combination Digital/Analog I/O Module

- Manufacturer: ABB

- Primary Application: ABB Industrial Robots (e.g., IRB series) and their controllers (e.g., IRC5)

- Key Function: Interfacing robot control with external field devices (sensors, actuators)

Part Three: Detailed Product Description

Have you ever watched an industrial robot perform intricate tasks, moving with seemingly effortless precision, grabbing an object, and placing it perfectly? This fluidity isn’t just about the robot’s mechanical design; it’s also about its ability to seamlessly interact with its environment. This is where modules like the ABB DSQC327A shine. It’s the robot’s “senses” and “limbs” to the outside world, translating complex digital instructions into physical actions and interpreting external conditions back into usable data for the robot’s brain.

I remember a project where we were setting up a new robotic welding cell. The robot needed to precisely track parts on a conveyor, detect their presence, and then activate specific clamps and welding torches. The original setup had separate digital and analog I/O modules, making wiring complex and troubleshooting difficult. By consolidating with a combination I/O module like the ABB DSQC327A, we significantly simplified the wiring, reduced the footprint in the control cabinet, and streamlined the programming. It made the entire integration process much smoother and easier to manage, proving that integrated solutions can be a real game-changer in complex automation tasks.

Versatile I/O for Complex Robotic Tasks: The ABB DSQC327A is a “Combi I/O” module, which means it integrates both digital and analog input/output functionalities onto a single board. While exact configurations can vary by specific revision, a common setup often includes around 8 digital inputs and 8 digital outputs, along with 4 analog inputs and 4 analog outputs.

- Digital I/O: These are used for simple on/off signals, like detecting if a part is present (digital input), or turning a gripper on/off (digital output). They handle discrete states.

- Analog I/O: These are used for continuous, variable signals, such as reading the distance from a laser sensor (analog input) or controlling the speed of a conveyor belt (analog output) based on a voltage or current signal.

This combination makes the DSQC327A incredibly versatile for a wide range of robotic applications, eliminating the need for multiple specialized modules and simplifying the overall system architecture.

Seamless Integration with ABB Robot Controllers: As an official ABB DSQC component, the DSQC327A is designed for seamless integration with ABB’s robot controllers, particularly the IRC5 family. This ensures:

- Native Compatibility: It plugs directly into the robot controller’s internal bus or designated I/O slots, guaranteeing optimal communication and performance.

- Simplified Configuration: Configuration is typically done through ABB’s RobotStudio software or directly via the FlexPendant, leveraging existing robot programming environments. This reduces setup time and complexity.

- Reliable Performance: Being part of the ABB ecosystem, it benefits from the rigorous testing and quality control associated with industrial robotics, ensuring high reliability and durability in demanding environments.

Robust Design for Industrial Environments: Industrial robots operate in challenging conditions. The DSQC327A is built to withstand these environments, featuring a robust design that can tolerate:

- Wide Operating Temperature Ranges: Typically from -20°C to +60°C.

- Vibration and Shock: Designed to perform reliably under mechanical stress.

- Electrical Noise Immunity: Built to resist interference from other industrial equipment, ensuring signal integrity.

Technical Specifications (Common for DSQC327A, may vary slightly by revision/specific part number like 3HAC17971-1):

Key Applications:

The ABB DSQC327A is essential in any application involving ABB industrial robots where interaction with external devices is required:

- Automotive Manufacturing: For robotic welding, painting, assembly, and material handling, interfacing with sensors for part detection, conveyors for material flow, and various tooling.

- Material Handling and Logistics: Robots used for picking, packing, palletizing, and de-palletizing, requiring connections to vision systems, conveyors, barcode scanners, and gripper controls.

- Machine Tending: Robots loading and unloading CNC machines, presses, or other production equipment, needing signals for machine status, part presence, and tool changes.

- Arc Welding and Spot Welding Cells: Precise control of welding parameters, gas flow, and safety interlocks, often using analog signals for fine-tuning.

- Food & Beverage Processing: Robots handling delicate items, requiring accurate feedback from sensors and precise control of end-effectors.

Related Products:

To form a complete robotic system around the ABB DSQC327A, you would need:

- ABB Robot Controller (e.g., IRC5): This is the core brain of the robot system where the DSQC327A module resides.

- ABB Industrial Robot (e.g., IRB series): The mechanical arm that performs the tasks.

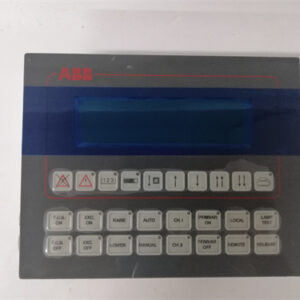

- ABB FlexPendant: The handheld operator interface for programming and controlling the robot.

- ABB RobotStudio Software: The PC-based simulation and programming tool for offline development and online monitoring.

- External Sensors: Such as proximity sensors, photoelectric sensors, vision systems, force sensors, or encoders that provide input signals to the DSQC327A.

- External Actuators: Such as pneumatic grippers, electric grippers, solenoid valves, or motor drives that receive output signals from the DSQC327A.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922