الوصف

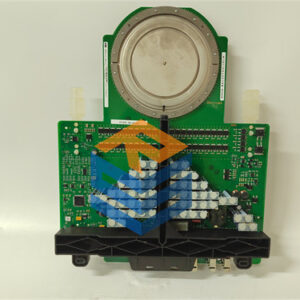

ABB SIEBEL&SCHOLL+IPS21-35AD DCS PLC Module

Product Name:

ABB SIEBEL&SCHOLL+IPS21-35AD DCS PLC Module

Product Description:

The ABB SIEBEL&SCHOLL+IPS21-35AD DCS PLC Module is a high-performance component designed for use in Distributed Control Systems (DCS) and Programmable Logic Controller (PLC) applications. Manufactured by ABB, a global leader in industrial automation, this module plays a crucial role in the control and monitoring of complex industrial processes, particularly in the oil & gas, power generation, chemical, and manufacturing industries.

The IPS21-35AD module is used for advanced data acquisition, control, and signal processing tasks. It offers superior flexibility in I/O configurations, extensive diagnostic features, and seamless integration with other automation systems. This makes it ideal for critical operations requiring high reliability, real-time response, and scalability. The module supports a variety of industrial communication protocols and integrates easily with other ABB control and automation systems, ensuring smooth operation and enhanced system performance.

Product Parameters:

-

Model Number:

SIEBEL&SCHOLL+IPS21-35AD -

Manufacturer:

ABB (Asea Brown Boveri) -

Type:

DCS PLC Module (Distributed Control System and Programmable Logic Controller) -

System Compatibility:

IPS21 Series and other ABB Distributed Control Systems (DCS), particularly suitable for industries such as power generation, chemical processing, oil & gas, and water treatment. -

Power Supply:

- Nominal Voltage: 24V DC

- Power Consumption: Varies depending on specific configuration.

-

Operating Temperature:

- Range: -40°C to +70°C (Standard industrial range)

-

Weight:

- Approximately 1.5 – 3 kg (depends on configuration)

-

Environmental Conditions:

- Humidity: Up to 95% (non-condensing)

- Vibration Resistance: Complies with industrial standards for high-reliability environments.

Specifications:

-

I/O Channels:

- Digital Inputs (DI): Configurable up to 32 channels

- Digital Outputs (DO): Configurable up to 32 channels

- Analog Inputs (AI): 8-16 channels for real-time data collection

- Analog Outputs (AO): 8-16 channels for controlling actuators or devices.

-

Processor:

- Real-Time Processing: The module is designed for real-time control of industrial processes.

- Control Algorithms: Supports control algorithms such as PID (Proportional, Integral, Derivative), cascade control, and advanced logic controls.

-

Memory:

- Sufficient onboard memory for control logic, I/O mapping, and system diagnostics.

-

Communication Protocols:

- Ethernet/IP: For high-speed data transfer and communication with other DCS modules and central control systems.

- Profibus: For integration with field devices and sensors in industrial environments.

- Modbus RTU/TCP: Widely used for communication with remote devices and sensors.

- HART: For communication with smart field devices.

-

System Integration:

- Seamless integration with ABB’s IPS21 Series and SIEBEL&SCHOLL DCS platforms for industrial control.

- Compatible with other ABB Automation and Control Systems, ensuring easy communication and data exchange.

-

Diagnostics and Monitoring:

- Onboard diagnostics for quick identification of faults and performance issues.

- Event logging: Provides logs of critical system events, alarms, and errors to assist in troubleshooting and maintenance.

-

Safety Features:

- Built-in safety features for SIL 2/SIL 3 applications, supporting safety-critical systems.

- Redundancy options available for critical components and communication paths to ensure high reliability and uptime.

-

Fail-Safe Operation:

- Redundant communication paths and power supplies ensure fail-safe operation in case of hardware or communication failures, making the module ideal for mission-critical applications.

-

Expansion:

- The module supports scalable configurations, allowing for easy expansion of I/O points, integration with additional control loops, and future system upgrades.

-

Mounting and Form Factor:

- Designed for rack-mounting in standard industrial control cabinets or panel-mounted enclosures.

- Equipped with LED indicators on the front panel for easy system status monitoring.

Key Features:

-

Advanced Real-Time Control:

The IPS21-35AD module offers real-time processing capabilities, ensuring that industrial processes are controlled with high speed and precision. -

Flexible I/O Configuration:

Supports a wide range of digital and analog I/O configurations, enabling it to adapt to various industrial applications. -

Integrated Diagnostics:

Features comprehensive self-diagnostics for quick identification of faults, improving maintenance and minimizing downtime. -

Redundant Systems:

Designed for high-reliability operations, the module offers redundancy options for communication and power to ensure fail-safe operation, even in critical environments. -

Industrial Communication:

Supports multiple industrial protocols like Ethernet/IP, Modbus, Profibus, and HART for integration with field devices and other systems. -

Scalability and Integration:

Easily scalable to meet the needs of growing systems and fully compatible with ABB’s IPS21 and SIEBEL&SCHOLL DCS systems. -

Safety Standards:

Supports SIL 2/SIL 3 standards, ensuring that it meets the requirements of safety-critical applications such as those found in oil & gas, chemical plants, and power generation. -

High-Performance Processing:

Capable of handling complex control algorithms and real-time data acquisition, making it suitable for advanced industrial control systems.

Applications:

The ABB SIEBEL&SCHOLL+IPS21-35AD module is used in a variety of industrial sectors, including:

- Power Generation: For control of power plants, turbines, and energy distribution systems.

- Oil & Gas: Used in refining, pipeline control, and offshore platform automation.

- Chemical Processing: For process control in chemical production, including reactors and batch processes.

- Water Treatment: For monitoring and control of water treatment plants, ensuring proper chemical dosing, filtration, and distribution.

- Manufacturing: In factory automation and large-scale manufacturing processes where real-time control is crucial.

Conclusion:

The ABB SIEBEL&SCHOLL+IPS21-35AD DCS PLC Module is a robust and reliable component designed for advanced process control in industrial automation systems. Offering real-time data processing, flexible I/O configurations, integrated diagnostics, and support for industrial communication protocols, it is ideal for mission-critical applications across industries like oil & gas, power generation, chemical processing, and manufacturing. With its scalable design, redundant systems, and safety features, the module ensures high performance, reliability, and safety in demanding industrial environments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922