الوصف

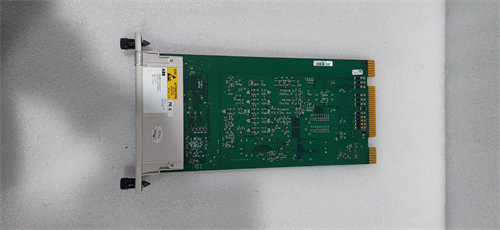

You’re asking about the ABB SPNPM22, which is a crucial component in ABB’s industrial automation portfolio. Specifically, the SPNPM22 is a Network Processing Module (NPM), commonly found in ABB’s Symphony Plus and older Bailey INFI 90 distributed control systems (DCS). This module is responsible for enabling high-speed, reliable communication and data exchange within complex plant networks. It’s the backbone that allows different parts of a control system to “talk” to each other effectively.

Enhanced SEO Titles

- ABB SPNPM22: Network Processing Module for Symphony Plus & INFI 90 DCS

- Optimize Plant Communications with ABB SPNPM22 Network Module

- SPNPM22: The Core of ABB’s Industrial Networking Solutions

- Enhance Data Exchange with ABB SPNPM22 Network Processor Module

- ABB SPNPM22: Reliable Communication for Critical Control Systems

- Seamless Connectivity: ABB SPNPM22 in Power Plants & Manufacturing

- Why ABB SPNPM22 is Essential for Distributed Control Architectures

- SPNPM22: ABB’s Solution for High-Performance Industrial Networks

- Streamline Automation with ABB SPNPM22 Network Integration

- ABB SPNPM22: Advanced Communication Module for Industrial Process Control

Brief Product Description

The ABB SPNPM22 is a Network Processing Module (NPM) designed for use within ABB’s distributed control systems, notably the Symphony Plus and Bailey INFI 90 platforms. Its primary function is to facilitate robust and high-speed data exchange across the industrial network. It acts as a communication hub, enabling seamless interaction between various control modules, input/output devices, and human-machine interfaces (HMIs) throughout the plant. The SPNPM22 ensures the efficient transfer of process data, alarms, and events, critical for maintaining the operational integrity, safety, and efficiency of large-scale industrial processes.

- Product Type: Network Processing Module (NPM)

- Manufacturer: ABB

- System Compatibility: ABB Symphony Plus, ABB Bailey INFI 90 DCS

- Primary Function: High-speed data exchange, network communication, and real-time data processing within industrial control networks.

Detailed Product Description

As an expert in industrial automation, I can tell you that in a large-scale industrial facility, a distributed control system (DCS) is like the central nervous system. And within that system, modules like the ABB SPNPM22 are the crucial neurons that enable rapid and reliable communication between all its parts. Without effective networking, even the most advanced control algorithms would fail to deliver their potential. The SPNPM22 is specifically engineered to handle the demanding communication requirements of critical industrial processes.

The ABB SPNPM22 serves as a vital bridge, connecting various control components within an ABB DCS environment, such as the Symphony Plus or the legacy Bailey INFI 90 systems. It facilitates the high-speed transfer of critical operational data, including real-time process variables, alarm statuses, event logs, and control commands. This ensures that every part of the system has access to the most up-to-date information, allowing for coordinated control actions and swift responses to changing plant conditions.

Core Functionality:

The main purpose of the SPNPM22 is to manage and process network traffic. It handles the low-level communication protocols, freeing up the main processor modules (CPUs) to focus on executing control logic. This specialization improves overall system performance and responsiveness. Key functionalities include:

- Data Exchange Master: The module efficiently manages the flow of large volumes of process data, alarms, and events across the network. This keeps operators, engineers, and other control elements informed in real-time.

- Distributed Control Enabler: By providing robust communication, the SPNPM22 enables the coordination of control tasks across multiple modules and controllers within the DCS. This allows for flexible and scalable system architectures, optimizing overall plant performance.

- Network Interface: It provides the physical and logical interface to the plant network, ensuring reliable communication pathways for all connected devices. This is crucial for maintaining system uptime and data integrity.

Robust Design for Industrial Environments:

The SPNPM22 is built to withstand the rigors of industrial environments. Its compact and sturdy design allows for easy integration into control cabinets without taking up excessive space. ABB’s reputation for quality means this module is engineered for durability and long-term use, even in challenging conditions such as those found in power plants, manufacturing facilities, or oil and gas operations.

Its compact dimensions and relatively light weight (around 0.28 kg or 0.62 lbs) make it easy to handle during installation and maintenance. The module typically features standard connectors for power and network cables, simplifying wiring.

Technical Specifications

Key Features and Advantages

- Reliable Network Communication: The SPNPM22 is designed for high reliability, ensuring stable and consistent data flow across complex industrial networks. This is critical for preventing communication failures that could lead to downtime or unsafe conditions.

- Optimized Data Exchange: It efficiently handles the transfer of process data, alarms, and events, keeping all connected modules and operators informed in real-time. This optimizes system performance and enables swift operational responses.

- Distributed Control Support: By facilitating robust communication between different control elements, it enables the implementation of distributed control strategies, enhancing system flexibility, scalability, and overall efficiency.

- Compact and Space-Saving Design: Its relatively small footprint allows for easy integration into control panels and cabinets, maximizing space utilization in crowded industrial environments.

- High-Quality Construction: Built to ABB’s stringent quality standards, the module is robust and durable, designed to withstand harsh industrial conditions and provide long-term, reliable service.

- Seamless Integration: As an integral part of ABB’s DCS platforms, it offers seamless plug-and-play compatibility with other ABB modules and systems, simplifying installation and reducing configuration efforts.

Application Areas

The ABB SPNPM22 Network Processing Module is essential in large-scale industrial operations that rely on robust and integrated control systems for safety, efficiency, and reliability. Its primary applications include:

- Power Plants: Used extensively in coal-fired, gas-fired, nuclear, and renewable energy power plants for monitoring and controlling power generation, distribution, and critical balance-of-plant systems. It ensures seamless communication between turbine controls, generator protection, and auxiliary systems.

- Oil & Gas Industry: Applied in upstream (drilling, production), midstream (pipelines), and downstream (refineries, petrochemical plants) operations. It facilitates communication for process control, safety instrumented systems, and asset management in highly demanding and often hazardous environments.

- Manufacturing Units: In large manufacturing facilities, including automotive, pulp and paper, and heavy industry, the SPNPM22 helps to integrate and automate complex production lines, ensuring smooth communication between various machinery, robots, and quality control systems.

- Water and Wastewater Treatment: In large municipal and industrial water treatment facilities, it enables the control and monitoring of pumps, valves, filtration systems, and chemical dosing, ensuring efficient and safe operations.

- Mining and Metals: Utilized in mining operations and metal processing plants for controlling crushing, grinding, refining, and smelting processes, where continuous and reliable communication is vital for safety and productivity.

Related Products

The ABB SPNPM22 operates within a larger ecosystem of ABB control system components. Here are some related products it would typically interact with:

- ABB Symphony Plus Controllers (e.g., SD Series Controllers like SPC600/700/800, HPC800): These are the main processing units that execute the control logic and communicate with the plant network via the SPNPM22.

- ABB Bailey INFI 90 Modules: For older INFI 90 systems, the SPNPM22 would interface with various INFI 90 processor and I/O modules.

- ABB SPNIS21 (Network Interface Slave Module): This module often complements the NPM by providing additional network interface capabilities.

- ABB I/O Modules (e.g., Digital Input/Output, Analog Input/Output modules): These modules connect to field devices (sensors, actuators) and transmit their data to the controllers, often routed through the network facilitated by the SPNPM22.

- ABB Rack and Power Supplies: The SPNPM22, like other DCS modules, is installed in a modular rack system that provides power and backplane communication.

- ABB Engineering Workstations and HMI Systems: These are the human interfaces where operators monitor processes, view alarms, and send commands. They rely on the network communication provided by the SPNPM22 to receive real-time data.

- ABB Ability™ Platform: Modern ABB systems integrate with the ABB Ability™ digital platform, which leverages data from modules like the SPNPM22 for advanced analytics, predictive maintenance, and operational optimization.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922