الوصف

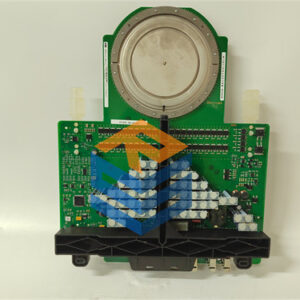

ABB 086406-002 PLC Module

Product Name:

- ABB 086406-002 – PLC Module

Product Description:

The ABB 086406-002 is a programmable logic controller (PLC) module designed for industrial automation and control systems. ABB, a global leader in industrial automation and robotics, produces this PLC module to provide precise control, monitoring, and diagnostics for complex industrial processes. This PLC module is used to integrate and control various devices in manufacturing lines, process control systems, and other industrial applications.

The 086406-002 model offers high flexibility and scalability, enabling users to customize the control solution to meet specific requirements for different automation tasks. With robust communication capabilities and various I/O configurations, the module can be employed in diverse industries such as automotive manufacturing, chemical processing, food and beverage production, and material handling.

It is engineered to handle tasks ranging from simple machine control to more complex systems requiring precise coordination of sensors, actuators, and other automation equipment.

Product Parameters & Specifications:

General Information:

- Model: ABB 086406-002

- Category: PLC Module

- Brand: ABB

- Application: Industrial Automation, Process Control, Machine Control

- Mounting: Typically designed for DIN rail or panel mounting in control panels.

- Power Supply: 24 VDC, Power Requirements: Varies depending on system load.

I/O Specifications:

-

Digital Inputs:

- The module supports a range of digital input points, typically 16 to 32 depending on configuration.

- Input Voltage: 24 VDC (standard industrial input logic).

- Can accept signals from switches, sensors, or proximity detectors.

-

Digital Outputs:

- Offers 16 to 32 digital output channels, typically 24 VDC.

- Output types may include sourcing or sinking depending on system configuration.

- Suitable for controlling external devices such as relays, motors, and actuators.

-

Analog Inputs:

- 4 to 20 mA or 0 to 10 VDC input ranges (common in industrial control applications).

- Number of channels may vary from 4 to 16 depending on the system setup.

- Ideal for processing sensor data such as temperature, pressure, flow, or position.

-

Analog Outputs:

- Includes analog output channels for controlling processes that require continuous signals, such as motor speed or position control.

- Output ranges typically include 0 to 10 VDC or 4 to 20 mA.

-

Communication Ports:

- RS-232/RS-485 serial communication for integration with external equipment or other PLCs.

- Ethernet or Ethernet/IP support for networked communication.

- Support for Modbus RTU/TCP, enabling connectivity with Modbus-compatible systems.

- Profibus and DeviceNet compatibility for more advanced control network systems.

Power Supply:

- Nominal Voltage: 24 VDC (common industrial standard)

- Voltage Range: 20.4 VDC to 28.8 VDC (allows for slight variations in input voltage).

- Power Consumption: Typically around 6W to 12W, depending on the configuration and connected devices.

Operating Conditions:

-

Operating Temperature:

- Typically ranges from 0°C to 60°C (32°F to 140°F) for normal industrial conditions.

-

Storage Temperature:

- Can be stored within -20°C to +70°C (-4°F to 158°F).

-

Humidity:

- Operates within 5% to 95% relative humidity (non-condensing).

-

Vibration Resistance:

- Designed to meet typical industrial standards for vibration resistance, usually IEC 60068-2-6.

-

Shock Resistance:

- Built to withstand shocks commonly encountered in industrial environments, typically compliant with IEC 60068-2-27.

-

Protection:

- IP20 rating (protection against solid objects larger than 12 mm, but no protection against water).

Communication and Control:

-

RS-232/RS-485:

- RS-232 for serial communication with various devices like sensors or controllers.

- RS-485 for multi-drop communication with additional external devices, ensuring long-distance communication (up to 1,200 meters) in industrial settings.

-

Ethernet/IP:

- Ethernet communication capabilities, making it easy to integrate into more complex networks, facilitating remote access, monitoring, and data exchange.

-

Modbus RTU/TCP:

- The module supports Modbus communication protocol, allowing integration with other Modbus-compatible devices for data sharing and control.

-

Profibus/DeviceNet:

- Support for Profibus or DeviceNet communication protocols, allowing for integration into industrial networks and seamless communication with field devices.

Diagnostics and Configuration:

-

Software Configuration:

- Configuration and programming are typically done using ABB’s proprietary software or compatible PLC programming tools.

- User-friendly interface allows for easy setup of I/O assignments, communication protocols, and control logic.

-

Diagnostic LEDs:

- Equipped with status LEDs for monitoring power, I/O status, and communication indicators, making troubleshooting easier.

-

Self-Diagnostics:

- Integrated self-diagnostic functions to help detect faults and errors in real-time.

- Error codes and event logs assist in quick identification of issues, allowing for minimal downtime.

-

Offline Programming and Simulation:

- Some configurations allow offline programming and simulation of control logic before going live.

Applications:

-

Industrial Automation:

- Ideal for controlling complex automation systems in industries such as automotive, packaging, material handling, pharmaceuticals, food and beverage, and more.

-

Process Control:

- Often employed in chemical, oil & gas, and water treatment industries where process stability and precision control are essential.

-

Machine Control:

- Used in machine tool automation, robotic systems, assembly lines, and test equipment for controlling actuators, sensors, and motors.

-

Building Automation:

- Can also be used for controlling HVAC systems, lighting, security systems, and other building management applications.

Key Features:

- Flexible Communication Options: Supports Ethernet/IP, RS-232, RS-485, Modbus, and Profibus for a wide range of integration options.

- Multiple I/O Types: Includes a mix of digital and analog inputs/outputs, allowing for versatile system control.

- Robust Diagnostics: LED indicators and built-in self-diagnostic tools ensure fast troubleshooting and minimal downtime.

- Compact and Durable: Designed for use in industrial environments

MSMA302D7V3 PLC

MFMA552D4V3

9905-020

6FC5203-0AF20-0AA1

1SBP260052R1001 PLC

6GK1571-1AA00 PLC

AVB-KF25-P PLC

SDCS-POW-4-SD PLC

SDCS-CON-4

S-D4007-K PLC

S-D4008-C PLC

3HAC024385-001 plc

3HAC14940-1 CPU

DR1030B60 CPU

IGP10A22E1FM1 PLC

IC695RMX128 PLC

DSQC377B CPU

OSA17-050 CPU

E-332B-6 CPU

IC698CPE030 PLC

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922