الوصف

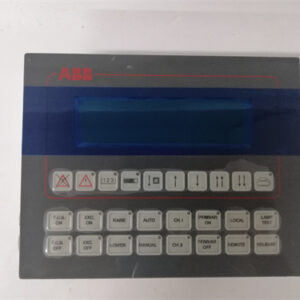

ABB 1TGB302003R0003 DCS PLC Module

Product Name:

ABB 1TGB302003R0003 DCS PLC Module

Product Description:

The ABB 1TGB302003R0003 is a Distributed Control System (DCS) PLC module used in industrial automation to provide reliable and efficient control for complex processes. ABB’s DCS solutions are highly regarded for their flexibility, scalability, and redundancy. This particular module is used in a variety of industries, including chemical, oil and gas, power, and water treatment, where continuous process control and real-time diagnostics are essential.

This module is part of ABB’s larger family of control systems, which combine advanced process control, safety, and automation in one system. The 1TGB302003R0003 module integrates seamlessly into the ABB System 800xA platform, offering high availability, redundancy features, and extensive I/O capabilities, all crucial for managing critical infrastructure in demanding environments.

Product Parameters:

- Model: 1TGB302003R0003

- Type: DCS PLC Module

- Manufacturer: ABB (Asea Brown Boveri)

- System Compatibility: Compatible with ABB System 800xA, AC800M, and AC800F controllers, and ABB Advant control systems.

- Power Supply:

- Nominal Voltage: 24 V DC (typically, but may vary with configuration).

- Current Consumption: Typically 2-3A (dependent on the system setup).

- Dimensions:

- Height: 17.0 cm

- Width: 10.5 cm

- Depth: 4.5 cm

- Weight: Approx. 0.8-1.2 kg

- Environmental Specifications:

- Temperature Range: 0°C to 60°C for operation

- Storage Temperature: -40°C to 85°C

- Humidity Range: 5% to 95%, non-condensing

- Vibration Resistance: Compliant with industrial standards for vibration.

Key Specifications:

-

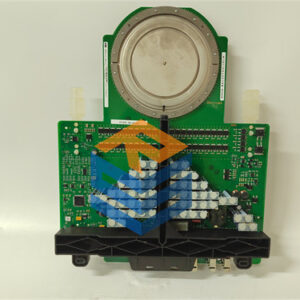

Processor:

- High-performance processor capable of executing advanced control algorithms in real-time.

- Multi-core architecture for parallel processing, ensuring that complex process control tasks are executed efficiently.

-

I/O Capability:

- Digital Inputs/Outputs (DI/DO): Configurable digital I/O for monitoring and control of devices like sensors, actuators, and relays.

- Analog Inputs/Outputs (AI/AO): High-precision analog I/O for continuous monitoring of process variables like temperature, pressure, and flow.

- Expansions: The system supports additional I/O modules, enabling scaling to handle larger systems or more diverse input/output types.

- Fieldbus Integration: Supports communication with field devices over Fieldbus, Modbus, and PROFIBUS networks.

-

Communication Protocols:

- Ethernet: For high-speed communication between modules and external systems.

- Modbus: Standard industrial communication for legacy and modern integration.

- PROFIBUS DP: For communication with field devices in industrial automation systems.

- HART: Protocol support for smart field devices.

- Redundant Ethernet: Optional for ensuring network reliability and failover.

-

Control Capabilities:

- Real-time control: Supports high-speed, real-time process control algorithms including PID (Proportional-Integral-Derivative), cascade control, and feedforward control.

- Process Control: Handles complex control loops, optimizing system performance with minimal human intervention.

- Redundant Control Channels: Dual or triple redundancy configurations for ensuring high availability and continuous operation.

- Safety Systems Integration: Compatible with SIL 2 and SIL 3 certified safety systems for integrating safety-related control functions.

-

Diagnostics and Monitoring:

- Self-Diagnostics: The module includes built-in diagnostic capabilities to monitor the health of the system.

- Event Logging: Captures alarms and events to facilitate troubleshooting and historical analysis.

- Redundant Systems: Ensures the control system continues to function in the event of hardware failure, with automatic failover to a redundant processor or path.

- Real-time Monitoring: Allows users to monitor critical parameters and system status remotely via System 800xA or web-based interfaces.

-

Safety Features:

- Safety Integrity Level (SIL): Supports SIL 2 and SIL 3 functions for safety-critical processes (depending on the configuration and the application).

- Fail-safe Operation: When a failure is detected, the system switches to a fail-safe state to ensure minimal risk to operations.

-

Integration:

- Software Compatibility: Fully compatible with ABB System 800xA, allowing for seamless integration with other ABB devices and systems.

- Human-Machine Interface (HMI): Integrates with ABB’s 800xA HMI for easy operation and control by plant operators.

- Web Access: Provides remote monitoring and diagnostics via a web interface, enabling off-site troubleshooting and analysis.

Key Features and Advantages:

-

Advanced Real-Time Control:

The ABB 1TGB302003R0003 module offers real-time control capabilities, including PID control, cascade control, and feedforward control, allowing for efficient and precise management of complex industrial processes. -

Redundancy for High Availability:

The system supports redundant configurations for both control and communication pathways, ensuring that the control system remains operational even in the event of hardware or network failure. -

Flexible I/O Expansion:

The module supports flexible I/O configurations, which can be expanded as the system requirements grow, making it suitable for both small and large-scale applications. -

Built-in Diagnostics and Alarms:

The system’s self-diagnostic functions provide operators with real-time insights into system health, while event logging and alarm management help identify faults quickly, minimizing downtime and maintenance costs. -

Safety Compliance:

The SIL 2 and SIL 3 certification options for safety-critical applications make it a reliable choice for industries where safety is paramount, such as chemical, oil and gas, and power sectors. -

User-Friendly Interface:

The ABB System 800xA HMI provides an intuitive interface for operators to control and monitor processes efficiently. The web-based access feature allows remote monitoring, making it easier to troubleshoot and maintain systems. -

Scalability:

The module can be integrated into larger systems with ABB’s modular control solutions, which allows for both vertical and horizontal scaling to accommodate growing operational requirements. -

Industrial Communication Standards:

The module supports Ethernet, PROFIBUS, Modbus, and HART protocols, which allow for seamless integration with existing equipment and sensors, reducing the need for extensive reconfiguration.

Applications:

The ABB 1TGB302003R0003 DCS PLC module is designed for industries requiring reliable process control, including:

- Oil and Gas: Offshore and onshore platforms, refining, pipeline monitoring.

- Power Generation: Nuclear, coal, and renewable energy plants.

- Chemical and Petrochemical: Batch processing, reactor control, and hazardous materials handling.

- Water and Wastewater Treatment: Municipal and industrial water treatment plants.

- Food and Beverage: Continuous processing and batch production lines.

Conclusion:

The ABB 1TGB302003R0003 is a robust and highly reliable DCS PLC module, offering advanced real-time control, redundancy, scalability, and integration with ABB’s System 800xA platform. Its suitability for safety-critical applications, combined with easy diagnostics and high availability features, makes it an ideal choice for industrial automation in critical sectors like oil and gas, power generation, and chemical processing.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922