الوصف

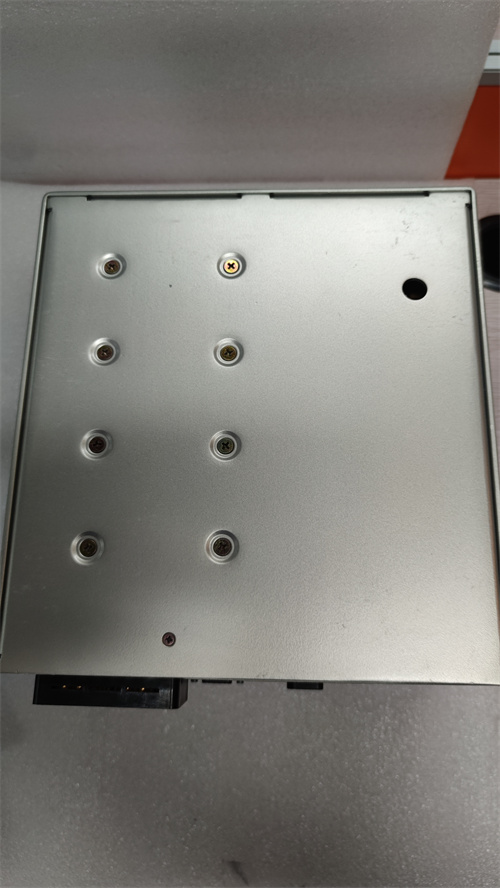

Product Name:

ABB +1VCF752000 DCS PLC Module

Product Description:

The ABB +1VCF752000 is a specialized module designed for integration within ABB’s Distributed Control System (DCS) and Programmable Logic Controller (PLC) systems. It is used for automating, controlling, and monitoring industrial processes in sectors such as oil & gas, power generation, chemical processing, and manufacturing. This module provides seamless communication between field devices (such as sensors, actuators, and other instrumentation) and the DCS/PLC, ensuring optimized control and reliable data processing. It supports advanced features like fault detection, diagnostics, and automation.

The +1VCF752000 module is typically used in industrial environments to handle complex control and monitoring tasks, providing robust communication and high-level data management. ABB’s modular systems are scalable and configurable, making them ideal for both small-scale and large-scale automation projects.

Product Parameters & Specifications:

General Information:

- Manufacturer: ABB

- Model/Part Number: +1VCF752000

- Type: DCS/PLC Module

- Module Type: I/O Interface or Communication Module (depending on specific configuration)

- Intended Application: Industrial control and automation in DCS and PLC systems

- Module Series: ABB’s DCS/PLC family, typically used in high-availability industrial automation and control systems

Functionality & Features:

-

I/O Processing:

- This module is used to interface field devices (such as sensors, actuators, and controllers) with the central DCS or PLC system.

- It supports analog and digital I/O capabilities, depending on the configuration.

-

Real-Time Control: Provides real-time data acquisition and control for automated systems, ensuring continuous and accurate feedback for operations.

-

Modular Design: The module is part of a modular automation system that allows for flexible configuration, scalability, and easy maintenance or upgrade.

-

Communication: The module facilitates communication between field devices and the PLC/DCS system, enabling seamless data transfer and control signals. It supports Ethernet or serial communication protocols such as MODBUS or PROFIBUS, depending on the system setup.

-

Advanced Diagnostics:

- The +1VCF752000 module provides real-time diagnostics, fault detection, and reporting features that help identify issues in the automation system and prevent downtime.

- Diagnostic features help optimize system performance and ensure operational reliability.

-

Safety and Reliability: The module is designed for robust performance in critical industrial environments with high availability and fault tolerance.

Input/Output Configuration:

- Inputs:

- Supports both digital and analog inputs, which can include sensors for pressure, temperature, flow, etc.

- Analog inputs usually support a range from 0-10V or 4-20mA signals.

- Digital inputs typically interface with on/off or high/low signals from field devices.

- Outputs:

- Analog Outputs: Provides control signals for actuators and devices, supporting voltage (e.g., 0-10V) or current (e.g., 4-20mA) outputs.

- Digital Outputs: Used to drive relays or on/off control of equipment, offering digital control of devices.

Power Supply:

- Operating Voltage: Typically 24V DC for industrial control systems.

- Power Consumption: The module’s power consumption varies based on the configuration but typically ranges from 5W to 15W.

Communication & Networking:

-

Communication Protocols:

- The +1VCF752000 module supports Ethernet/IP, PROFIBUS, MODBUS, or other standard industrial protocols for communication with other modules, field devices, and control systems.

- Real-Time Communication: The module ensures that communication between field devices and the central system is efficient and operates with minimal delay.

-

Redundancy and Fault Tolerance:

- ABB’s systems often offer redundancy for critical applications, ensuring system uptime in the event of a failure.

- Features include dual communication paths or backup systems for ensuring continuous operation.

Environmental & Physical Specifications:

- Operating Temperature: Typically in the range of -20°C to +70°C (-4°F to 158°F), depending on the module.

- Storage Temperature: Typically -40°C to +85°C (-40°F to 185°F).

- Humidity: The module can operate in environments with 0% to 95% relative humidity, non-condensing.

- Vibration: Built to withstand industrial-level vibrations often found in manufacturing or oil & gas settings.

- Protection Class: Designed to meet industry-standard protection ratings such as IP20, though more specific ratings depend on the installation and enclosure configuration.

Diagnostics & Maintenance:

- Built-in Diagnostics: Provides diagnostic feedback for system health, including fault detection, error reporting, and troubleshooting.

- LED Indicators: Typically equipped with LED lights for visual indication of system status, such as power, communication, or fault conditions.

- Configuration and Maintenance: Supports configuration and maintenance through ABB’s automation software (such as Automation Builder or Control Builder) for easy setup and ongoing system management.

Software & Configuration:

- ABB Automation Software:

- Configuration and programming of the +1VCF752000 module can be done through ABB’s Automation Builder or Control Builder, which allow for seamless integration into the broader control system.

- These software tools also provide diagnostic tools, logging, and remote troubleshooting features.

- System Integration:

- The +1VCF752000 module is designed to integrate into ABB’s larger automation and control systems, which can include other DCS/PLC modules and controllers.

- It can work with a wide range of field devices and systems for monitoring and control, allowing for a highly integrated approach to industrial automation.

Key Features & Benefits:

- Modular and Scalable: The module is part of a modular control system, allowing easy scaling and expansion based on process requirements.

- Flexible I/O: Supports both analog and digital I/O for a wide range of field devices, including sensors, actuators, and controllers.

- Real-Time Control: Enables real-time process control and automation, critical for industries requiring continuous monitoring.

- Advanced Diagnostics: Includes built-in diagnostic features that help with fault detection and predictive maintenance, ensuring high system availability.

- Communication Flexibility: Compatible with various industrial communication protocols such as Ethernet/IP, MODBUS, and PROFIBUS, allowing for easy integration into existing control systems.

- Reliable & Robust: Designed for use in demanding industrial environments, offering durability, redundancy, and fault tolerance.

- User-Friendly Configuration: Easy integration and configuration with ABB’s software tools, reducing setup time and operational complexity.

Applications & Use Cases:

- Oil & Gas: For process control and monitoring in upstream and downstream operations, including drilling, refining, and pipeline monitoring.

- Power Generation: To control and monitor turbines, boilers, and generators in power plants.

- Chemical Processing: For managing production processes, ensuring the safe operation of reactors, mixers, and storage systems.

- Manufacturing: Automation of production lines, quality control, and machine management.

- Water Treatment: Monitoring and control of pumps, filtration systems, and chemical dosing units in water treatment plants.

Conclusion & Recommendation:

The ABB +1VCF752000 DCS/PLC Module is a highly versatile and reliable component designed to automate and optimize industrial processes. With its flexibility, advanced diagnostic capabilities, and seamless integration into ABB’s larger automation ecosystem, it is an ideal solution for industries such as oil & gas, power generation, chemical processing, and manufacturing. The module enhances operational efficiency, reduces downtime, and improves overall system reliability, making it an essential part of modern industrial control systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922