الوصف

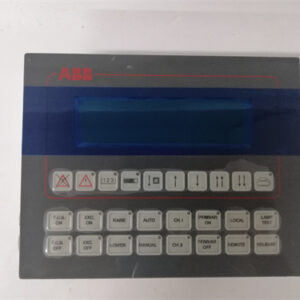

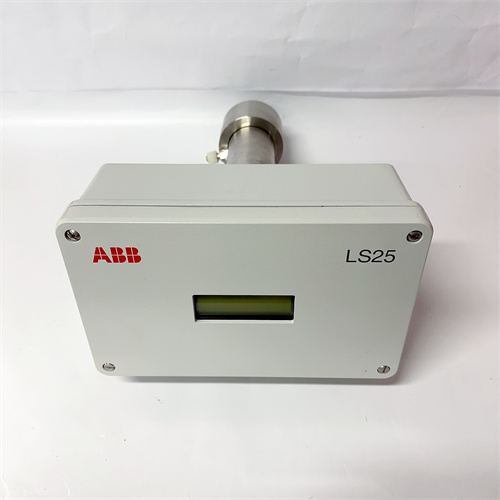

Product Name

ABB AO2000 LS25 Analog Output Module

Product Description

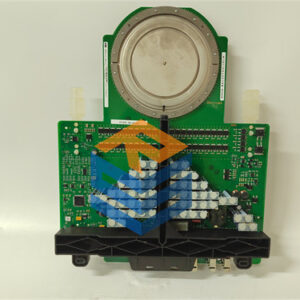

The ABB AO2000 LS25 is an analog output module designed for use with ABB’s distributed control systems (DCS) and programmable logic controllers (PLCs). As a crucial component in industrial automation, the ABB AO2000 LS25 module provides precise and reliable analog signal outputs to control various field devices such as valves, actuators, and drives. The robust design of the ABB AO2000 LS25 ensures dependable performance even in harsh industrial environments. With its advanced features and diagnostics, the ABB AO2000 LS25 enables efficient process control and monitoring, contributing to improved operational efficiency and reduced downtime. The ABB AO2000 LS25 is a high-performance solution for demanding industrial applications.

Product Parameters

- ABB+AO2000 LS25

- Output Channels: 8

- Output Signal: 0-20 mA, 4-20 mA, 0-10 V, ±10 V (configurable)

- Resolution: 16 bits

- Accuracy: ±0.1% of full scale

- Isolation Voltage: 500 VDC

- Power Supply: 24 VDC

- Operating Temperature: -25°C to +70°C

- Communication Interface: PROFIBUS DP, Modbus TCP/IP, EtherNet/IP (depending on the specific system)

- Diagnostics: Channel-specific error detection, wire break detection, short-circuit detection

Advantages and Features

- High Accuracy and Resolution: Ensures precise control of analog signals, crucial for demanding applications.

- Configurable Output Ranges: Offers flexibility to adapt to different field devices and control requirements.

- Comprehensive Diagnostics: Simplifies troubleshooting and reduces downtime by providing detailed error information.

- Robust Design: Withstands harsh industrial environments, ensuring reliable performance.

- Galvanic Isolation: Protects the control system from ground loops and electrical noise.

- Easy Integration: Seamlessly integrates with ABB’s DCS and PLC systems, as well as other control platforms.

- Advanced Functionality: Features such as output signal clamping and scaling enhance control capabilities.

Application Areas and Application Examples

- Chemical Industry: Control of valves and pumps for precise chemical dosing and mixing.

- Oil and Gas: Regulation of flow rates and pressures in pipelines and refineries.

- Power Generation: Control of steam turbines and boiler systems.

- Water and Wastewater Treatment: Regulation of chemical feed pumps and valve positioning for water treatment processes.

- Pharmaceuticals: Precise control of temperature and pressure in reactors and fermentation processes.

- Manufacturing: Control of actuators and drives in automated production lines.

Example: In a chemical plant, the ABB AO2000 LS25 module can be used to precisely control the flow of chemicals into a reactor. The module receives a control signal from the PLC and adjusts the output current to a control valve, ensuring accurate and consistent chemical dosing. This precise control helps to maintain product quality and reduce waste.

Competitive Product Comparison

| Feature | ABB AO2000 LS25 | Siemens ET 200MP AO8 | Allen-Bradley 1756-OF8 |

|---|---|---|---|

| Output Channels | 8 | 8 | 8 |

| Output Signal | 0-20 mA, 4-20 mA, 0-10 V, ±10 V | 0-20 mA, 4-20 mA, ±10 V | 0-20 mA, 4-20 mA, 0-10 V, ±10 V |

| Resolution | 16 bits | 16 bits | 16 bits |

| Accuracy | ±0.1% of full scale | ±0.1% of full scale | ±0.05% of full scale |

| Isolation Voltage | 500 VDC | 500 VDC | 500 VDC |

| Operating Temperature | -25°C to +70°C | 0°C to +60°C | -20°C to +65°C |

| Diagnostics | Channel-specific, wire break, short-circuit | Channel-specific, wire break | Channel-specific, wire break, short-circuit |

The ABB AO2000 LS25 provides a balance of features and performance compared to competitors like Siemens and Allen-Bradley. While Allen-Bradley may offer slightly higher accuracy, the ABB AO2000 LS25 provides a wider operating temperature range.

Selection Advice

- Application Requirements: Determine the required number of output channels, signal types, and accuracy.

- Environmental Conditions: Consider the operating temperature and humidity of the installation environment.

- System Compatibility: Ensure compatibility with the existing control system and communication protocols.

- Diagnostics: Evaluate the importance of diagnostic features for troubleshooting and maintenance.

- Budget: Compare the cost of different modules and consider the total cost of ownership, including installation, maintenance, and potential downtime.

- Future Expansion: Choose a module that can accommodate future expansion and upgrades.

Precautions

- Proper Installation: Follow the manufacturer’s instructions for proper installation and wiring.

- Overvoltage Protection: Use surge suppressors to protect the module from voltage spikes.

- Grounding: Ensure proper grounding to prevent ground loops and electrical noise.

- Regular Maintenance: Perform regular inspections and maintenance to ensure optimal performance.

- Environmental Protection: Protect the module from excessive heat, humidity, and dust.

- ESD Protection: Handle the module with care to prevent electrostatic discharge damage.

We are your trusted partner, offering sales and technical support for ABB AO2000 LS25 and other automation components. Contact us for special discounts and pricing – we are here to serve you!

ABB+AO2000 LS25

| PR6480/041-000 I/O |

| PR6480/031-000 |

| PR6480/001-100 PLC |

| PR6480/001-000 PLC |

| PR6470/646-120 PLC |

| PR6470/223-120 |

| PR6470/222-110 PLC |

| PR6453/361-000 PLC |

| PR6453/341-001 DCS |

| PR6453/201-SDR PLC |

| PR6426/010-140 PLC |

| PR6426/010-000 PLC |

| PR6426/010-131 I/O |

| PR6426/010-130 PLC |

| PR6426/010-120 PLC |

| PR6426/010-110 PLC |

| PR6426/010-100 PLC |

| PR6426/010-040 PLC |

| PR6426/010-030 PLC |

| PR6426/010-020 PLCPLC |

| PR6426/010-010 |

| PR6426/000-141 |

| PR6426/000-140 PLC |

| PR6426/000-131 PLCCPU |

| PR6426/000-130 PLC |

| PR6426/000-121 PLC |

| PR6426/000-111 PLC |

| PR6426/000-110 PLC |

| PR6426/000-101 PLC |

| PR6426/000-100 PLC |

| PR6426/000-041 |

| PR6426/000-040 PLC |

| PR6426/000-031 PLC |

| PR6426/000-030 PLC |

| PR6426/000-021 PLC |

| EPRO PR6426/000-020 |

| PR6426/000-010 PLC |

| PR6426/000-001 PLC |

| PR6426/000-000 PLC |

| PR6425/010-A20 PLC |

| PR6425/010-141 PLC |

| PR6425/010-140 PLC |

| PR6425/010-130 PLC |

| PR6425/010-110 PLC |

| PR6425/010-100 PLC |

| PR9670/111-100 PLC |

| PR9670/110-100 PLC |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922