الوصف

Product Name:

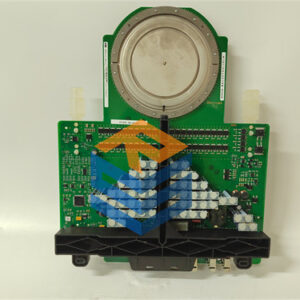

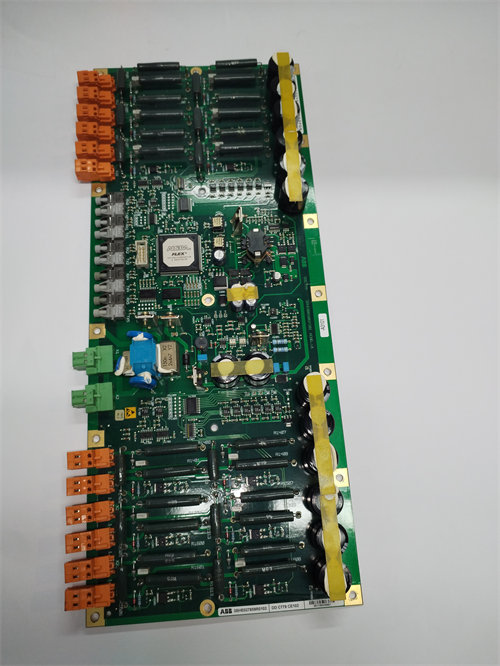

ABB DDC779CE102 3BHE027859R0102 DCS PLC Module

Product Description:

The ABB DDC779CE102 3BHE027859R0102 is a Distributed Control System (DCS) PLC module designed and manufactured by ABB, a leader in automation and control technologies. This specific module is a key component within ABB’s 800xA or 5/6/7 series control systems, tailored for high-performance real-time process control in complex industrial settings. The module provides advanced capabilities for controlling and monitoring industrial processes across sectors such as chemical production, oil & gas, power generation, and manufacturing.

Designed to support scalability and high redundancy, the DDC779CE102 module integrates seamlessly into distributed control systems, ensuring efficient management of data flow between field devices, controllers, and supervisory systems. It features an array of digital and analog I/O points for field communication, as well as various networking and communication protocols for compatibility with other control systems. This module is built for reliability, ease of integration, and robustness in challenging industrial environments.

Product Parameters:

- Module Type: DCS PLC Control Module for process automation and control systems.

- System Compatibility: Compatible with ABB 800xA or similar ABB control systems, providing a unified architecture for industrial automation.

- I/O Capacity: Supports a wide range of digital and analog I/O channels, adaptable to specific industrial needs.

- Communication Protocols: Supports multiple protocols like Modbus, Profibus, Ethernet/IP, and ABB proprietary communication standards.

- Redundancy: Features redundant power supplies, fieldbus communication, and I/O channels to ensure high reliability and system uptime.

- Field Device Integration: Fully integrates with a broad spectrum of field devices, including sensors, actuators, and motors.

- Mounting and Installation: Designed for DIN rail or rack mounting depending on the installation environment.

Product Specifications:

1. Processor and Performance:

- Processor:

- The DDC779CE102 module features a high-performance processor capable of executing real-time control loops with minimal latency. This ensures precise and responsive control of complex processes in industries requiring critical performance metrics.

- Real-Time Control:

- Optimized for real-time data processing, the module can handle fast response times and efficiently control processes such as temperature, pressure, flow, and level.

2. Memory:

- RAM:

- The module typically includes dynamic RAM (ranging from 4MB to 32MB), enabling rapid execution of control logic and the ability to handle large volumes of real-time process data.

- Non-Volatile Memory:

- Includes EEPROM or Flash Memory for storage of critical parameters, configurations, and control programs, allowing recovery and continuity in case of power failure.

3. I/O and Expansion:

- I/O Capacity:

- The module supports both digital (on/off) and analog (continuous variable) I/O channels, configurable for a wide range of field devices like sensors, actuators, and valves.

- Expansion Modules:

- The DDC779CE102 offers modular expansion for adding more I/O points, communication ports, or redundancy options based on system needs.

4. Communication and Networking:

- Communication Protocols:

- The module supports several communication standards, such as Modbus, Profibus DP, Ethernet/IP, and ABB proprietary communication protocols, allowing for smooth integration with a variety of control systems, devices, and network architectures.

- Redundant Communication:

- Provides built-in redundancy for Ethernet and fieldbus communications, ensuring continuous data flow and minimizing system downtime in case of communication link failures.

5. Power Requirements:

- Operating Voltage:

- The DDC779CE102 module typically operates at 24V DC or 48V DC, with redundant power supplies for increased system reliability and uptime.

- Power Consumption:

- The module’s power consumption typically ranges from 30W to 50W, depending on the I/O configuration and connected devices.

6. Environmental Specifications:

-

Operating Temperature Range:

- The module is rated for a temperature range of -20°C to +60°C, making it suitable for a wide variety of industrial environments.

-

Humidity:

- It operates in environments with 5% to 95% non-condensing humidity.

-

Protection Rating:

- Typically rated IP20, meaning it is protected from dust and water ingress, but more robust models may support higher ratings, such as IP65.

-

Shock and Vibration Resistance:

- Meets IEC 60068 standards for shock and vibration resistance, ensuring that the module can operate in environments subject to mechanical stress.

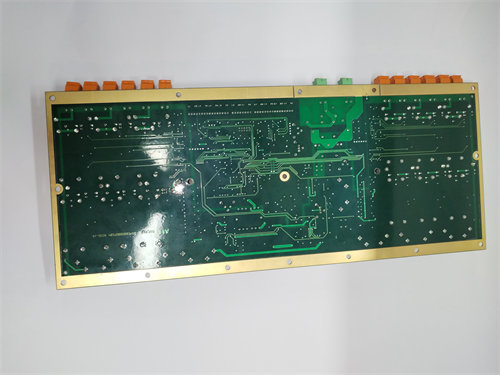

7. Physical and Mechanical Specifications:

- Form Factor:

- Designed for DIN rail or rack mounting, depending on the specific installation requirements.

- Dimensions:

- Approximate dimensions are typically in the range of 160 mm x 120 mm x 60 mm (Height x Width x Depth), though this can vary slightly based on the specific configuration and model.

- Weight:

- The weight of the module is typically around 1.5 kg to 2.0 kg, depending on the configuration and I/O options.

Key Features and Benefits:

-

Scalability and Flexibility: The DDC779CE102 module is easily scalable, making it suitable for small systems as well as large, complex installations. It can grow with your needs by adding more I/O points or communication ports.

-

Real-Time Control: The module offers fast processing and low-latency response for controlling industrial processes, ensuring precise and accurate control of critical variables like temperature, pressure, and flow.

-

High Redundancy and Reliability: It supports redundant power supplies, communication paths, and field devices, ensuring that the system can continue to operate even in the event of hardware failure, making it suitable for mission-critical applications.

-

Seamless Integration: Designed to integrate easily with existing ABB systems, such as the 800xA DCS, this module offers extensive compatibility with other devices and third-party systems, allowing for easy system expansion and integration.

-

Enhanced Diagnostics and Maintenance: Equipped with self-diagnostics and status monitoring features, the module makes it easier to detect faults, identify issues, and perform maintenance, reducing system downtime and improving operational efficiency.

Applications:

-

Power Generation: Used for turbine control, generator systems, and boiler control in thermal, hydro, and nuclear power plants.

-

Oil & Gas: Ideal for managing pipeline monitoring, offshore platforms, and refinery processes where reliability and real-time control are critical.

-

Chemical Processing: Used for controlling complex chemical processes such as reactor management, distillation, batch processing, and dosing.

-

Manufacturing and Automation: Controls production lines, robotics, and automated manufacturing systems, optimizing efficiency and precision in industrial production.

-

Water Treatment and Distribution: Applies to water treatment plants, desalination plants, and wastewater systems to manage filtration, chemical dosing, and flow control.

Conclusion:

The ABB DDC779CE102 3BHE027859R0102 DCS PLC Module offers high-performance control and monitoring solutions for industrial automation. Its ability to integrate seamlessly with ABB 800xA control systems, coupled with its scalable architecture, ensures that it can meet the needs of a wide range of industries, including oil and gas, chemical processing, power generation, and manufacturing. With features like redundancy, real-time control, and robust communication protocols, the module ensures optimal operational performance and high system reliability in demanding industrial environments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922