الوصف

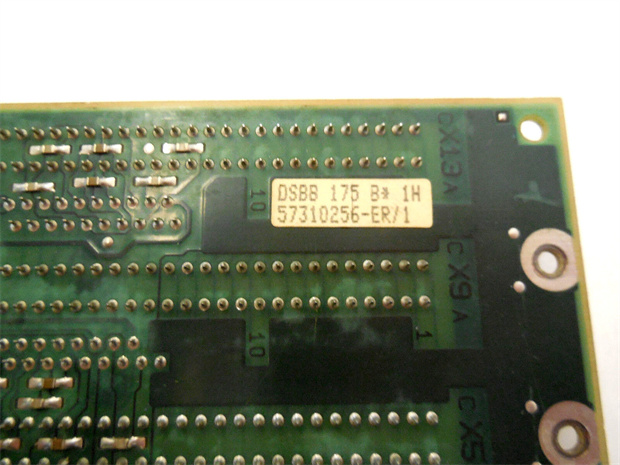

Product Name:

ABB+DSBB175 DCS PLC Module

Product Description:

The ABB+DSBB175 is a Distributed Control System (DCS) module designed for high-performance industrial automation and control applications. It is part of ABB’s extensive DCS portfolio, offering robust process control, monitoring, and communication functionalities suited for industries such as oil and gas, chemical manufacturing, power generation, and pharmaceuticals. The DSBB175 module is engineered to provide reliable, fault-tolerant, and scalable solutions for process control, ensuring consistent performance in critical industrial operations.

This module supports advanced diagnostics, real-time monitoring, and flexible I/O configuration, which are key features for seamless integration into automated control systems. With its modular design and extensive communication capabilities, the ABB+DSBB175 provides a flexible, scalable, and high-availability solution for large and complex industrial plants.

Product Parameters & Specifications:

General Specifications:

- Model: ABB+DSBB175

- Type: DCS (Distributed Control System) PLC Module

- Manufacturer: ABB

- Primary Use: Industrial process control, monitoring, and automation

- Module Integration: Part of ABB’s DCS systems (used in a wide range of industrial applications)

- Functionality: High-performance PLC/DCS module offering critical process control, monitoring, and fault tolerance.

Key Features:

- Modular Design: The DSBB175 module is part of a modular DCS system, allowing for scalable, customized solutions based on system requirements.

- Fault-Tolerant and Redundant Architecture: Designed with redundant components for power supplies, processors, and communication paths, ensuring reliability in critical environments where downtime must be minimized.

- Real-Time Process Control: Provides real-time control of industrial processes with advanced features such as PID control, sequencing, and loop control.

- Flexible I/O Configuration: Supports various analog and digital I/O modules to suit specific control and automation needs across different industrial applications.

- Advanced Diagnostics and Monitoring: Includes built-in diagnostics and monitoring tools to detect and respond to system faults and performance issues, allowing for proactive maintenance.

- Multiple Communication Protocols: Supports Ethernet, Modbus, RS-485, and other communication standards for seamless integration into existing automation networks.

- User-Friendly Configuration: Compatible with ABB’s Control Builder or other software for easy system configuration, programming, and troubleshooting.

Electrical Specifications:

-

Power Supply:

- Typically operates on a 24V DC power supply.

- Redundant power supply options for improved reliability in critical applications.

-

Power Consumption:

- Optimized to consume minimal power, making it an energy-efficient solution for continuous industrial operation.

-

Input Voltage Range:

- Standard 24V DC input, with tolerance for voltage fluctuations commonly found in industrial environments.

-

Communication Protocols:

- Supports Modbus RTU/TCP, Ethernet/IP, and RS-485 for communication between devices and external controllers.

Mechanical Specifications:

-

Form Factor:

- Designed for rack-mounted installation in a 19-inch control rack.

-

Dimensions:

- Typically 3U high, with varying depth and width depending on the specific configuration.

-

Cooling:

- Requires adequate ventilation for passive cooling in industrial racks. Active cooling may be needed in high-temperature environments.

-

Weight:

- Approximate weight: 1.5 – 2.5 kg, depending on the model configuration.

Environmental Specifications:

-

Operating Temperature:

- Rated for -20°C to +60°C operating temperature, suitable for most industrial environments.

-

Storage Temperature:

- -40°C to +85°C for safe shipping and storage.

-

Relative Humidity:

- Operates effectively within 5% to 95% non-condensing relative humidity.

-

Vibration and Shock Resistance:

- Meets industrial vibration standards, ensuring durability in dynamic environments.

-

Ingress Protection:

- Typically rated IP20, providing basic protection from dust and accidental contact.

Functional Specifications:

-

I/O Support:

- Supports a wide range of digital and analog inputs and outputs, offering flexibility in control and automation applications.

- Ideal for both high-speed I/O processing and low-speed control applications.

-

Redundancy:

- Features redundant processors and communication channels for high availability, ensuring continuous operations even in the event of component failure.

-

Safety and Fault Detection:

- Built-in fault detection and event logging capabilities to alert operators about system issues and help with troubleshooting.

-

Real-Time Monitoring:

- The module supports real-time diagnostics and performance monitoring to ensure system health and performance.

-

Control and Automation:

- Facilitates PID control, sequence control, and feedback loop regulation, which are essential in applications requiring precise control of process variables.

Software and Configuration:

- Configuration Software:

- ABB Control Builder or other ABB configuration tools can be used to configure and monitor the DSBB175 module.

- Diagnostic Tools:

- Advanced diagnostic and troubleshooting tools allow for remote monitoring and troubleshooting, which reduces downtime and improves maintenance efficiency.

Applications:

- Oil & Gas:

- Used for critical process control in upstream and downstream oil & gas operations, including pipeline and refinery automation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922