الوصف

Product Overview

Product Name:

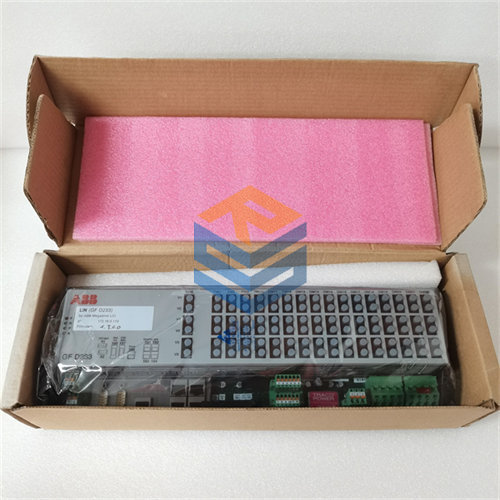

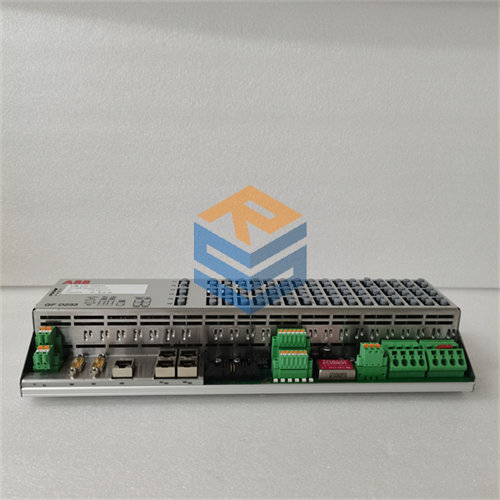

ABB GFD233A103 3BH022294R0103 DCS PLC Module

Product Description:

The ABB GFD233A103 3BH022294R0103 is part of ABB’s comprehensive portfolio of Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC), designed to provide reliable, flexible, and scalable solutions for industrial automation. This module is commonly used in process control, energy management, automation, and manufacturing systems, offering high availability, redundancy, and comprehensive diagnostic features for mission-critical applications.

The module integrates seamlessly within ABB’s 800xA and ProControl systems, enabling industries to monitor, control, and optimize complex operations. Its robust design is tailored to meet the needs of environments that demand high precision, operational continuity, and data integration across various field devices, sensors, and actuators.

Key Features:

- Designed for Industrial Applications: Primarily used in process industries, power generation, and manufacturing where reliability and real-time control are essential.

- Modular and Scalable Design: Enables easy integration and expansion within existing automation systems.

- High Availability and Redundancy: Supports redundant configuration for critical applications requiring continuous, uninterrupted operations.

- Advanced Diagnostics: Integrated diagnostic tools help quickly identify faults, ensuring system reliability.

- Communication Flexibility: Supports standard communication protocols like Modbus, Ethernet/IP, and Profibus, ensuring smooth integration with other control systems.

Product Parameters and Specifications:

1. Model:

- Model Number: GFD233A103 3BH022294R0103

- Series: ABB 800xA or ProControl DCS Series

- Module Type: I/O Module / Control Module

2. I/O Capacity:

- Analog Inputs: Typically configurable for 4-20mA or 0-10V signal ranges.

- Digital Inputs: Generally 8, 16, or 32 digital inputs, depending on the configuration.

- Digital Outputs: Configurable for relay or transistor outputs.

- Analog Outputs: 4-20mA or 0-10V ranges for controlling process variables.

3. Power Supply:

- Power Input: Typically requires 24V DC (for most of ABB’s DCS and PLC modules).

- Redundant Power: Some configurations support dual power supplies for enhanced reliability.

4. Processor and Memory:

- Processor: High-speed microprocessor designed for real-time control and monitoring.

- Memory: Sufficient onboard memory (ranging from 256MB to 1GB, depending on module configuration) for control logic, data logging, and diagnostics.

5. Communication Protocols:

- Modbus RTU/TCP: Used for serial and Ethernet-based communication.

- Ethernet/IP: Supports integration into modern Ethernet-based control networks.

- Profibus DP: For connecting with field devices and remote I/O.

- HART: For communication with smart field devices, providing diagnostic and configuration data.

- DeviceNet / CANOpen: For communication with lower-level field devices.

6. Redundancy Features:

- Processor Redundancy: Configurable for hot standby mode to ensure system reliability and minimize downtime.

- Power Redundancy: Supports redundant power supplies for uninterrupted system operation.

7. Environmental Ratings:

- Operating Temperature: Generally supports a wide range, from -20°C to +60°C (specific ranges depend on the environment).

- Humidity: Rated for 5% to 95% non-condensing.

- Vibration Resistance: Typically rated for 5g acceleration.

- Shock Resistance: Often rated for 15g shock or more.

8. Compliance and Standards:

- CE Marking: Compliant with European safety and EMC standards.

- UL Approval: Available for specific configurations, meeting North American safety standards.

- SIL (Safety Integrity Level): Designed to meet safety requirements for critical control applications in industries like power, petrochemical, and process industries.

9. Mounting and Integration:

- Rack Mountable: Designed for easy installation in standard control racks and panels.

- Modular Design: Facilitates scalable configurations depending on the needs of the application.

- Fieldbus Support: Integrated support for fieldbus networks and distributed I/O.

Applications:

The GFD233A103 3BH022294R0103 DCS PLC module is designed for use in a range of applications, including:

-

Power Generation:

- Turbine control (gas and steam turbines).

- Generator control.

- Power plant automation (including fossil and renewable energy sources).

-

Process Control:

- Chemical, petrochemical, and pharmaceutical manufacturing.

- Water treatment and waste management.

- Food and beverage processing.

-

Industrial Automation:

- Automated manufacturing lines and robotics.

- Factory floor automation for control of production equipment.

- Building automation for HVAC, lighting, and security systems.

-

Oil & Gas:

- Drilling operations and refinery control.

- Process monitoring and control for offshore and onshore facilities.

-

Transportation & Infrastructure:

- Control systems for railway, airports, and traffic management systems.

Conclusion:

The ABB GFD233A103 3BH022294R0103 DCS PLC module offers a reliable and flexible solution for industrial automation, especially in process control, power generation, and manufacturing. With features like redundancy, modular design, and support for various communication protocols, this module can be integrated into large-scale control systems, ensuring high availability and continuous operation in mission-critical environments. Its diagnostic capabilities help enhance operational efficiency, and its rugged design ensures it performs well in harsh industrial conditions.

By integrating ABB’s 800xA or ProControl system, industries can optimize their production processes while ensuring safety, reliability, and scalability.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922