الوصف

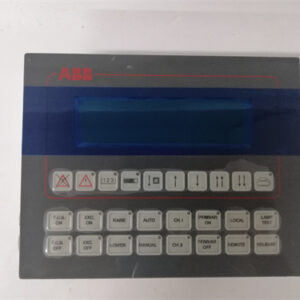

ABB MB810 DCS/PLC Module

Product Name:

ABB MB810 – I/O Module for Distributed Control Systems (DCS)

Product Description:

The ABB MB810 is a versatile input/output (I/O) module designed for use in ABB Distributed Control Systems (DCS), specifically compatible with the 800xA and Freelance automation systems. This module allows for the integration of various field devices into the control system, providing both analog and digital I/O capabilities. The MB810 is optimized for a wide range of industrial applications, offering high flexibility, reliability, and easy integration into process control and automation systems.

The MB810 module is particularly suitable for industries such as chemical, oil & gas, energy, and water treatment, where real-time data collection and control are essential. It is designed to enhance system performance by providing reliable and accurate I/O processing.

Key Features:

- Multi-Function I/O Module: Supports both analog and digital I/O signals, including thermocouple, RTD, and discrete inputs/outputs.

- Real-Time Communication: Provides real-time data communication with other DCS or PLC components.

- High Flexibility: Compatible with different types of field devices and various industrial control applications.

- Modular Design: The MB810 module can be integrated with other modules to create scalable and adaptable control systems.

- Built-In Diagnostics: Includes LED indicators for monitoring the status of inputs, outputs, power, and communication.

- High Reliability: Designed for harsh industrial environments, ensuring continuous and stable operation.

Product Parameters & Specifications:

-

Module Type: I/O Module for Distributed Control Systems (DCS)

-

Module Code: MB810

-

Application Area: Industrial process automation, real-time data exchange, process control systems.

-

Input/Output Types:

-

Analog Inputs (AI):

- Number of Inputs: Typically up to 8 channels for analog inputs.

- Supported Signal Types: 4-20 mA, 0-20 mA, 0-10 V.

- Input Resolution: Typically 16-bit (depends on model).

- Input Accuracy: High accuracy suitable for precision applications.

- Supported Sensors: Thermocouples, RTDs, current/voltage signals.

-

Analog Outputs (AO):

- Number of Outputs: Typically 4 channels.

- Supported Signal Types: 4-20 mA, 0-20 mA, 0-10 V.

- Output Resolution: Typically 16-bit.

- Accuracy: High performance for precise control in process applications.

-

Digital Inputs (DI):

- Number of Inputs: Typically 16 discrete inputs.

- Input Voltage: Supports 24V DC, 120V AC, or 240V AC depending on configuration.

- Signal Type: Discrete on/off signals (e.g., switches, relays).

-

Digital Outputs (DO):

- Number of Outputs: Typically 16 discrete outputs.

- Output Type: Relay outputs or transistor outputs (depending on configuration).

- Voltage: Typically 24V DC, 120V AC, or 240V AC.

- Output Load: Suitable for controlling a wide range of actuators and field devices.

-

-

Communication Protocols Supported:

- Communication Interface: The MB810 module integrates seamlessly with ABB’s 800xA and Freelance DCS systems.

- Communication Protocols: Supports protocols like Modbus, Profibus, Ethernet/IP, and ABB proprietary communication standards.

- Fieldbus Support: Compatible with multiple fieldbus protocols, enabling connection to various types of field devices and systems.

-

Power Supply:

- Operating Voltage: Typically 24V DC, but other configurations can be supported.

- Power Consumption: Approximately 15W (depending on the configuration and the number of channels being used).

- Redundant Power Support: Supports redundancy to ensure high availability and fault tolerance in mission-critical environments.

-

Environmental Specifications:

- Operating Temperature: Typically -20°C to +60°C.

- Storage Temperature: Typically -40°C to +85°C.

- Humidity: 5% to 95% relative humidity (non-condensing).

- Vibration Resistance: Designed to meet industrial standards for vibration resistance.

- Ingress Protection (IP Rating): Typically IP20 (depending on the enclosure type and model).

-

Physical Characteristics:

- Mounting: Rack-mountable in standard DCS enclosures.

- Dimensions (L x W x H): Varies depending on specific model configuration but typically in the range of 150 mm x 100 mm x 40 mm.

- Weight: Approx. 1 kg (depending on configuration).

-

Status Indicators:

- LED Indicators: Displays status of power, communication, I/O channels, and diagnostics.

- Built-in Diagnostics: Provides real-time information about the health of the module, including fault detection for inputs, outputs, and system status.

-

Redundancy and Fault Tolerance:

- Hot-Backup Support: The module supports hot-standby redundancy in the event of failure to maintain continuous operation.

- Redundant Power Supplies: Supports dual power supply inputs for increased reliability in critical applications.

Applications:

- Process Control Systems: The MB810 is ideal for industries such as chemical processing, petrochemical, water treatment, and power generation.

- Manufacturing Automation: Used in manufacturing plants for controlling machines, processes, and equipment.

- Energy and Utilities: Integrates into power generation, distribution, and utility monitoring and control systems.

- Safety Systems: Can be used in applications requiring safety monitoring, emergency shutdown systems, and alarm systems.

- Remote Monitoring: Suitable for remote monitoring and data collection via networked connections, especially when integrated into ABB’s 800xA or Freelance systems.

Benefits:

- Versatility: The MB810 offers flexible I/O options for a wide range of applications, supporting a combination of analog, digital, and special signals.

- Ease of Integration: Fully compatible with ABB’s 800xA and Freelance DCS platforms for seamless integration into existing control systems.

- Real-Time Control: Provides real-time processing for mission-critical applications requiring constant monitoring and control.

- Reliability: Designed for continuous operation in industrial environments with redundancy and diagnostic capabilities.

- Cost-Effective: Offers a cost-efficient solution for process control and automation, with scalability for system expansion.

Conclusion:

The ABB MB810 I/O module is an essential component in ABB Distributed Control Systems (DCS), particularly for industries that require flexible and reliable I/O processing. Its capability to support both analog and digital signals, combined with its robust communication protocols and fault tolerance features, makes it an ideal solution for applications in process control, manufacturing automation, energy management, and safety systems.

If you need more details on how it works with specific ABB control systems or need assistance with configuration, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922