الوصف

Here is the detailed information for the ABB NU8976A99 DCS PLC Module:

Product Name

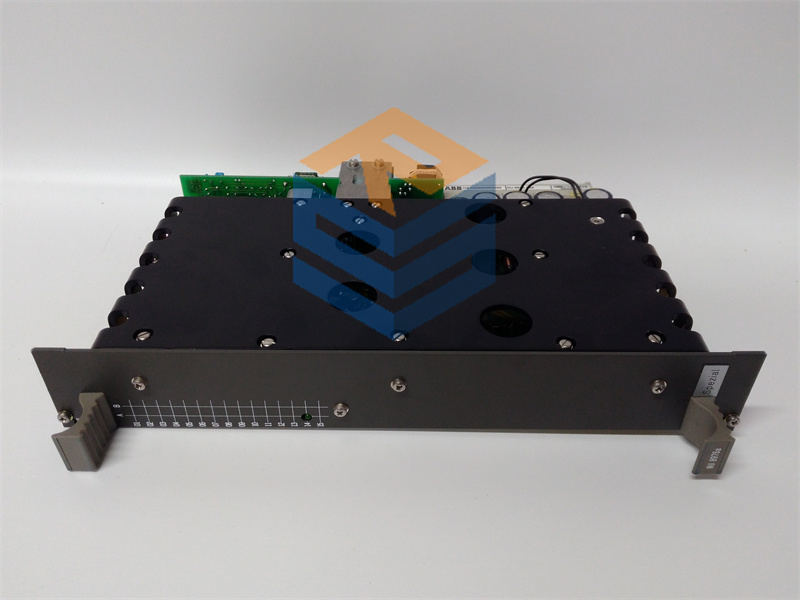

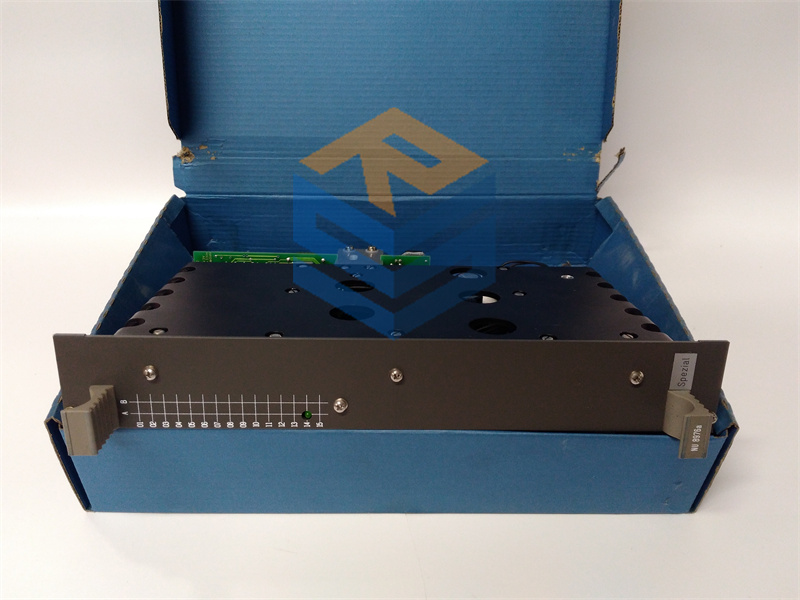

ABB NU8976A99 DCS PLC Module

Product Description

The ABB NU8976A99 is a highly reliable and flexible Distributed Control System (DCS) Programmable Logic Controller (PLC) module designed to offer high-performance control and automation capabilities in a wide range of industrial applications. This module is part of ABB’s 800xA automation system and integrates seamlessly into ABB’s range of advanced process automation solutions.

The NU8976A99 is ideal for applications where real-time data processing, high availability, and robust fault-tolerant performance are required. It offers scalable I/O configurations, advanced diagnostics, and powerful communication capabilities, making it suitable for industries such as power generation, oil and gas, chemicals, manufacturing, and utilities. This module is specifically built to handle complex processes and ensure maximum uptime in mission-critical operations.

Product Parameters & Specifications

- Model: ABB NU8976A99

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) Module

- Processor:

- High-performance CPU capable of executing complex control algorithms in real-time.

- Embedded controller optimized for fast processing and decision-making.

- Memory:

- RAM: 512MB (standard), with optional upgrades based on system configuration.

- Flash Memory: 256MB (expandable), offering non-volatile storage for critical applications.

- Power Supply:

- Nominal Voltage: 24V DC

- Operating Voltage Range: 20V to 30V DC

- Power Consumption: Typically 10W to 20W, depending on configuration.

- Communication Protocols:

- Ethernet (for high-speed data communication)

- Modbus TCP/IP

- Profibus DP

- DeviceNet

- HART (for field device communication)

- ABB proprietary protocols for integration with ABB 800xA and other systems.

- I/O Configuration:

- Digital Inputs: 16-64 channels (configurable)

- Digital Outputs: 16-64 channels (configurable)

- Analog Inputs: 8-32 channels (configurable)

- Analog Outputs: 8-32 channels (configurable)

- Supports a wide variety of I/O modules for flexibility in configuring systems.

- Redundancy:

- Dual processor configuration for fault tolerance and high availability.

- Redundant power supplies (optional) for continuous operation even during power failures.

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +85°C

- Humidity: 5% to 95%, non-condensing

- Mounting Type: Rack-mounted (standard 19” form factor)

- Dimensions:

- Height: 3U (standard rack size)

- Width: 19 inches (standard form factor)

- Depth: 180-250 mm (depends on configuration)

- Weight: Approximately 3-5 kg (varies with configuration)

- Safety and Compliance:

- CE Mark

- UL Certification

- IECEx Certification for hazardous locations (optional versions available)

- Environmental Rating: Designed for industrial environments, with protection against dust, moisture, and temperature extremes.

Key Features

- Real-Time Control:

- Designed for mission-critical applications that require high-speed data processing, real-time control, and low-latency communication for precise operations.

- Redundancy and High Availability:

- Dual-processor architecture and optional redundant power supplies to minimize downtime and ensure operational continuity in demanding environments.

- Modular and Scalable:

- A modular approach to system design allows for easy configuration of I/O modules, ensuring adaptability to various industrial applications and future growth.

- Seamless Communication:

- The module supports multiple industry-standard communication protocols such as Ethernet, Modbus TCP/IP, and Profibus DP, providing flexible and reliable communication across different system components.

- Advanced Diagnostics and Monitoring:

- Built-in diagnostic tools for real-time monitoring and troubleshooting, offering predictive maintenance capabilities to avoid unexpected failures.

- High Reliability:

- Suitable for continuous, high-performance control in critical applications requiring high availability, reliability, and fault tolerance.

- Safety and Compliance:

- Designed to meet international safety standards, ensuring safe operations in regulated environments.

Applications and Use Cases

The ABB NU8976A99 is well-suited for applications in industries that require robust, high-performance control systems. Some key use cases include:

- Power Generation:

- Real-time control of power plants, including turbines, boilers, and auxiliary systems.

- Oil & Gas:

- Automation of drilling rigs, pipelines, compressors, and separators.

- Chemicals and Petrochemicals:

- Managing chemical reactors, distillation columns, and process units.

- Manufacturing:

- Control of production lines, assembly systems, and automated machinery in factories.

- Water & Wastewater Treatment:

- Control of pumps, filtration systems, chemical dosing, and monitoring equipment.

- Pharmaceutical:

- Ensuring precise, regulatory-compliant control in pharmaceutical manufacturing processes.

Selection and Integration Considerations

When selecting and integrating the ABB NU8976A99 DCS PLC Module, it’s important to consider the following:

- I/O Requirements:

- Ensure that the module configuration aligns with your required I/O count and types. ABB offers a range of modules for digital, analog, and specialty I/O to meet various application needs.

- Redundancy Needs:

- For critical applications, configure the module with redundant processors and power supplies to maintain system availability during faults or maintenance.

- Communication Network:

- Ensure compatibility with your existing communication infrastructure. The module supports multiple protocols such as Modbus, Profibus, and Ethernet, which should integrate easily with your existing network.

- Environmental Conditions:

- Verify that the module meets the operating temperature, humidity, and environmental protection needs for your specific industrial environment.

- Future Scalability:

- Consider future growth and expansion of your system. The modular nature of the ABB system ensures that the module can scale to accommodate future demands.

Conclusion

The ABB NU8976A99 DCS PLC Module is a reliable, high-performance control solution designed to meet the demands of modern industrial automation. With flexible configurations, robust redundancy, and advanced diagnostics, this module is suited for use in a wide range of industries, including power, oil & gas, chemicals, and manufacturing. Its adaptability, scalability, and compliance with safety standards make it an ideal choice for critical and mission-critical applications.

If you need any more details or clarification on specific aspects of the module, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922