الوصف

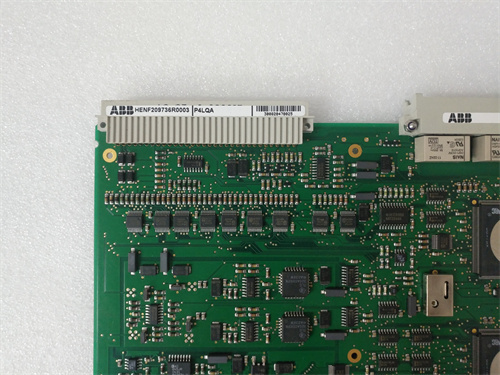

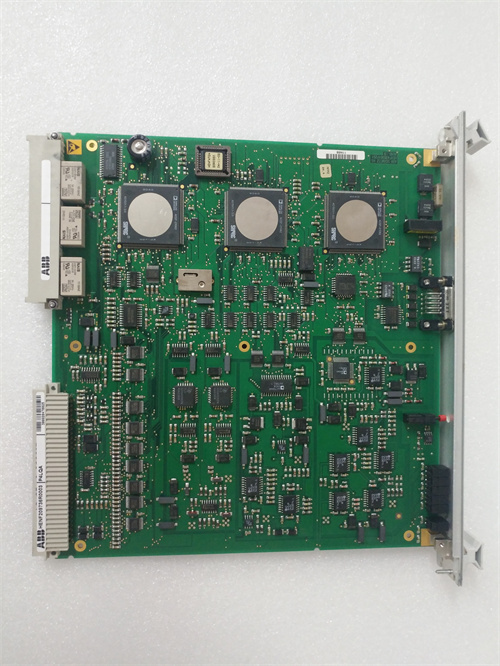

ABB P4LQA HENF209736R0003 PLC Module

Product Name:

ABB P4LQA HENF209736R0003 – PLC Module

Product Description:

The ABB P4LQA HENF209736R0003 is an advanced programmable logic controller (PLC) module designed to support high-performance automation systems, often used in industrial processes, manufacturing, and energy management applications. As part of ABB’s comprehensive control solutions, this PLC module offers modular functionality, robust processing power, and flexibility for complex control tasks.

The P4LQA HENF209736R0003 is designed for industrial environments that demand high reliability, scalability, and real-time control. It integrates with ABB’s larger control and automation systems and can be used for a range of applications, from machine control to process optimization and energy management. The module supports I/O expansion, communication integration, and advanced diagnostic features to optimize performance and maintain system reliability over time.

This PLC module is suitable for both small-scale and large-scale automation systems where flexibility, precision, and scalability are essential. It’s built to withstand the harsh conditions of industrial environments and can be integrated with various devices, sensors, and systems for real-time monitoring and control.

Key Features:

-

High-Performance Processing:

- Designed for high-speed and precise control of automation systems, ensuring real-time data processing for mission-critical applications.

-

Modular Architecture:

- The P4LQA PLC module has a modular design, allowing it to be expanded with additional I/O modules and communication interfaces to meet system demands.

-

Communication Protocols:

- Supports multiple communication standards such as Ethernet, Modbus, and CAN for seamless integration with other PLCs, sensors, and devices across diverse industrial systems.

-

Flexible I/O Expansion:

- The system is scalable, supporting the addition of various digital and analog I/O modules for expanded control capabilities.

-

Advanced Diagnostics:

- Includes diagnostic tools for system monitoring, fault detection, and preventive maintenance, ensuring high system uptime and reliability.

-

Industrial Compatibility:

- Built for use in rugged industrial environments, offering protection against environmental factors like vibration, temperature variation, and electromagnetic interference (EMI).

-

Energy Management:

- Ideal for energy control systems, helping to monitor and manage energy consumption, optimize processes, and ensure sustainable operation in industrial plants.

Product Parameters & Specifications:

General Information:

-

Model:

- ABB P4LQA HENF209736R0003 PLC Module

-

Category: PLC Module

-

Brand: ABB

-

Part Number: HENF209736R0003

-

Application: Industrial Automation, Energy Management, Process Control, Machine Control

Power Supply:

-

Nominal Voltage: 24V DC (typical for industrial PLC modules).

-

Input Voltage Range:

- Typically 20V to 30V DC.

-

Power Consumption:

- Approx. 15W to 30W, depending on the configuration and load.

Operating Conditions:

-

Operating Temperature Range:

- -20°C to +60°C (-4°F to 140°F), ensuring stable operation across industrial environments.

-

Storage Temperature Range:

- -40°C to +85°C (-40°F to 185°F).

-

Relative Humidity:

- 5% to 95%, non-condensing.

-

Protection Rating:

- Typically IP20 for the module itself; additional protection may be provided when mounted inside an enclosure.

-

Vibration Resistance:

- Meets industrial vibration and shock standards.

I/O Specifications:

-

Digital I/O:

- Supports discrete inputs and outputs for controlling simple on/off devices such as relays, switches, and valves.

-

Analog I/O:

- Capable of handling analog inputs (e.g., temperature, pressure) and analog outputs (e.g., motor control, actuator feedback).

-

I/O Expansion:

- Supports expansion modules for adding additional I/O points (both digital and analog), enabling scalable system control.

-

Communication Ports:

- Ethernet, Modbus, CAN, and possibly RS-232/RS-485 for direct communication with other devices.

Performance & Control Features:

-

Processing Speed:

- High-speed control and processing capabilities, allowing the PLC to handle complex logic and real-time control applications.

-

Control Algorithms:

- Supports a range of control algorithms for applications in machine control, process optimization, and energy management.

-

Redundancy Features:

- Optional redundancy configurations for critical systems, ensuring continued operation during maintenance or failure of components.

-

Advanced Diagnostics:

- Built-in self-diagnosis tools, including system health checks, error reporting, and troubleshooting features for proactive maintenance.

Compliance & Certifications:

-

Safety Standards:

- Compliant with international standards such as UL, CE, and CSA, ensuring the PLC is safe for use in various global markets.

-

Electromagnetic Compatibility (EMC):

- Meets EMC standards to prevent electromagnetic interference in industrial environments.

Applications:

-

Industrial Automation:

- Used in factories, manufacturing plants, and production lines to control and monitor automated processes.

-

Energy Management:

- Ideal for power plants, substations, and renewable energy systems, offering energy control, monitoring, and optimization.

-

Process Control:

- Suitable for applications requiring precision control in chemical, food and beverage, and pharmaceutical industries.

-

Machine Control:

- Common in systems for controlling robotics, conveyors, and other complex automated machinery.

-

Building Management Systems:

- Used in HVAC systems, lighting control, and security systems to monitor and control building environments efficiently.

Summary of Key Features:

- High-performance control for both small and large-scale automation systems.

- Flexible I/O expansion for adaptable system configurations.

- Advanced diagnostics for continuous monitoring and system reliability.

- Multiple communication protocols for easy integration with other devices and systems.

- Energy management capabilities for optimization of energy consumption in industrial processes.

- Industrial-grade durability, designed to function reliably under harsh conditions.

If you need any further details about the ABB P4LQA HENF209736R0003 PLC Module or have specific questions, feel free to ask!

ABB TB845 PLC

A0801 ABB PLC

ABB TB846 PLC

DI801 PLC

ABB TK801V003

XYCOM XVME-674 PLC

XVME-564 PLC

XYCOM XVME-630 PLCDCS

DI801 ABB

ABB TK801V003

DI802

TK801V006 PLC

DI803 PLC

ABB PP820 PLC

ABB PP825

ABB PP826 I/O

TB810 ABB PLC

ABB PP835 PLC

TB811 PLC

PP836 ABB PLC

PP845 ABB PLC

ABB PP846 PLC

ABB TB842 PLC

ABB TU807 PLC

ABB PP865 PLC

ABB TU840 PLC

PP871 ABB PLC

TU848 ABB I/O

ABB PP874

PP87Z ABB PLC

ABB TU849 PLC

TK854V030 ABB

ABB CB801 PLC

CB810 ABB

ABB TK811V015 PLC

ABB TK811V050 PLCDCS

TK811V150 ABB PLC

ABB TK812V015 PLC

ABB TK812V050 PLC

ABB TK812V150 PLC

ABB TB815 PLC

PP815 ABB PLC

ABB DLM01 PLCI/O

ABB DCP10 PLC

DDI01 PLC

ABB DCP10 PLC

DDI02 ABB DCS

DDI02 ABB PLCDCS

ABB DLM02 PLC

ABB DDI03

DLM02 ABB DCS

DAI01 ABB

RX835 ABB DCS

ABB DAI01 I/O

DDI03 ABB PLC

ABB RX865 DCS

ABB DDI04 PLC

DAI02 ABB PLC

ABB DDI04 PLC

ABB DAI02 PLC

DAIO3T ABB IO

ABB DDI05 I/O

ABB DAIO3T PLC

DAI04 ABB PLC

DAI05 ABB PLC

ABB DA001 PLC

DCP02 PLC

DLM01 PLC

DD003 ABB PLC

ABB DDO03 PLC

ABB DDO04 PLC

ABB DDO004 DCS

ABB DCO01 PLC

ABB DCO01 PLC

DFI01 ABB PLC

ABB DFI01 PLC

ABB DRA02 I/O

ABB DRAO3 PLC

ABB DRAO3 PLC

ABB DPW01 PLC

DPW01 ABB PLC

ABB DRA04 PLC

ABB DRA04 PLC

ABB DPW03 I/O

ABB DPW02 I/O

ABB DPW02 PLC

DDI05 ABB PLCI/O

ABB DPW03

DD001 ABB

ABB DDO01

ABB DDO02 I/O

ABB 3BSE003911R0001 DCS

ABB 3BHB001336R0001 DCS

ABB 3BHE009017R0102

3BHB003387R0101 ABB

3BSE000863R0001 ABB

ABB 3BSE003-911R0001

ABB 3BHE013299R0002

ABB 3BHE021887R0101

2CCA183111R0001 ABB

ABB 3BHB000272R0001 DCS

3BSE004086R0001 ABB

ABB XVC770BE101 I/O

CI810A I/O ABB

ABB CI810A

ABB 3BSE003911R000

ABB 3BHB004027R0101

ABB 3BHE003379R0003

ABB 3BHE004059R0001 DCS

ABB 3BSE004940R0001 CPU

3BHB007030R0001 ABB

3ADT211033R0001 ABB

ABB 3BHE003485R0001

ABB 3BHE024855R0101

ABB 3BSC610022R0001 DCS

ABB SDCS-KU2001

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922