الوصف

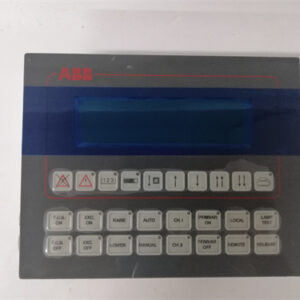

Product Name:

ABB PDD500A101 DCS PLC Module

Product Description:

The ABB PDD500A101 is a high-performance Distributed Control System (DCS) and Programmable Logic Controller (PLC) module designed for industrial automation applications. It is part of ABB’s 800xA control system, specifically designed for integrating process automation with scalable, reliable, and high-performance control solutions. The PDD500A101 module combines the advantages of a robust PLC with advanced DCS capabilities, making it suitable for complex industrial processes that require high-speed control, safety, and flexibility.

Designed for industries such as oil & gas, chemical processing, power generation, and manufacturing, this module can handle both discrete and continuous processes, offering seamless integration into various control networks and systems. With its fault-tolerant design and advanced diagnostics, the PDD500A101 ensures system reliability and uptime in mission-critical applications.

Product Parameters & Specifications:

Module Type:

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) Module

- Manufacturer: ABB

- Model/Part Number: PDD500A101

- Series: ABB 800xA

Input/Output Configuration:

- Digital Inputs (DI): Typically 8-32 digital inputs, depending on configuration.

- Digital Outputs (DO): Typically 8-32 digital outputs.

- Analog Inputs (AI): 4-8 analog inputs for continuous signals, such as from pressure or temperature sensors.

- Analog Outputs (AO): 2-4 analog outputs for controlling actuators, such as valves and motors.

Note: The exact number of I/O channels can vary depending on specific configurations and modules, as ABB offers flexibility in terms of expansion and application needs.

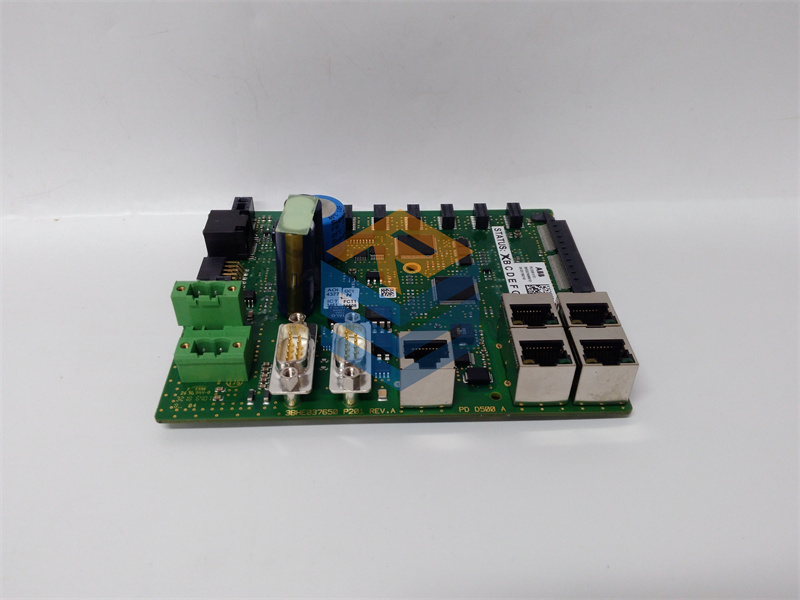

Communication Protocols:

- Fieldbus Integration: Supports ABB’s proprietary communication protocols, such as AC800M or AC800F controllers.

- Modbus RTU/TCP: Integration with Modbus protocols for communication with other devices in industrial automation systems.

- PROFIBUS/PROFINET: Compatible with PROFIBUS and PROFINET for integration into existing industrial networks.

- Ethernet/IP: Provides communication via Ethernet/IP, ensuring high-speed data transfer and integration within Ethernet-based networks.

- HART: Supports the HART protocol for digital communication with smart field instruments, such as transmitters and analyzers.

Control and Performance:

- Real-Time Processing: Real-time processing for high-speed control and monitoring of industrial systems.

- Processing Speed: Designed to handle high-performance requirements, capable of executing control algorithms with minimal delay.

- Response Time: Fast response times suitable for time-critical processes in industries such as oil & gas and chemical processing.

Power Supply:

- Operating Voltage: Typically 24 V DC, ensuring compatibility with industrial control systems.

- Power Consumption: Low power consumption suited for industrial automation needs.

Environmental Specifications:

- Operating Temperature: Typically -20°C to +60°C (-4°F to +140°F), designed for harsh industrial environments.

- Storage Temperature: -40°C to +85°C (-40°F to +185°F), suitable for storage in extreme conditions.

- Humidity: Works in environments with 5% to 95% relative humidity (non-condensing).

- Vibration Resistance: Built to withstand industrial vibration levels, ensuring long-term reliability in dynamic environments.

Redundancy & Reliability:

- Redundant Power Supply: The module is designed to support redundant power configurations, ensuring system reliability and fault tolerance.

- Failover Support: The PDD500A101 supports automatic failover mechanisms to reduce the risk of downtime in mission-critical applications.

- Diagnostic Tools: The system includes advanced diagnostics for monitoring system health, performance, and for detecting faults early.

Safety & Compliance:

- Safety Integrity Level (SIL): The module is designed to meet SIL 2 or higher safety integrity levels, depending on the specific configuration and application.

- Standards: Complies with international standards such as IEC 61508 for functional safety, and IEC 61511 for safety instrumented systems (SIS).

- Certifications: Typically meets CE, UL, and other international safety and compliance standards, making it suitable for deployment worldwide.

Software & Programming:

- Programming Environment: Configured and programmed using ABB’s Engineering Tools, such as Control Builder and System 800xA software.

- Programming Languages: Supports IEC 61131-3 programming languages, including Ladder Logic (LD), Structured Text (ST), Function Block Diagram (FBD), and Sequential Function Charts (SFC).

- Configuration Software: Tools such as Control Builder are used for system configuration, programming, and diagnostics.

Diagnostics & Monitoring:

- Built-in Diagnostics: The module includes comprehensive diagnostic tools that provide real-time system health monitoring and fault detection, which is essential for minimizing downtime and ensuring smooth operation.

- LED Indicators: Provides LED status indicators for easy system status monitoring and troubleshooting.

- Alarms and Alerts: Capable of generating alarms and alerts based on system or process deviations, allowing operators to take immediate corrective action.

Key Features & Benefits:

-

High-Performance Control:

- The PDD500A101 combines the robustness of a PLC with the flexibility and scalability of a DCS system, making it ideal for complex process control applications.

-

Scalable and Modular:

- The PDD500A101 is part of ABB’s 800xA system, offering flexibility for system expansion and scalability to accommodate growing or changing industrial needs.

-

Advanced Diagnostics:

- With integrated diagnostics and fault detection capabilities, this module provides quick identification of system issues, ensuring high reliability and uptime.

-

Redundant Power and Failover:

- Redundant power supply options and automatic failover mechanisms ensure that the system remains operational even in the event of power failures or hardware issues.

-

Industry Compliance:

- Designed to meet global safety and compliance standards, the PDD500A101 is suitable for deployment in highly regulated industries such as oil & gas, chemical, pharmaceuticals, and power generation.

-

Real-Time Processing:

- With its ability to handle real-time processing, the module is ideal for applications that require quick responses, such as automated manufacturing or continuous process control.

-

Flexible I/O Options:

- With a range of I/O options, including digital and analog inputs and outputs, the module is versatile and can be tailored to specific application needs.

-

Integrated Control System:

- The PDD500A101 integrates seamlessly into ABB’s 800xA control system, allowing for centralized monitoring, control, and diagnostics from a single interface.

Applications & Use Cases:

- Oil & Gas: Used in the automation and monitoring of processes like refining, offshore platforms, and pipeline control.

- Chemical Processing: Ideal for controlling chemical reactions, mixing, and ensuring safety in chemical plants.

- Power Generation: Monitoring and controlling turbine operations, power generation, and electrical grid distribution.

- Manufacturing: Controls various manufacturing processes, from discrete manufacturing to continuous process lines in industries like automotive and electronics.

Conclusion & Recommendation:

The ABB PDD500A101 DCS PLC Module is a highly reliable and versatile control solution, ideal for industries with complex and safety-critical applications. With real-time control, advanced diagnostics, and high-performance capabilities, it offers a robust solution for industries such as oil & gas, chemical processing, power generation, and manufacturing. The integration with ABB 800xA further enhances its scalability, flexibility, and ease of use. This module is recommended for users seeking a high-performance, fault-tolerant control solution for mission-critical industrial applications.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922