الوصف

The ABB PFEA113-20 (3BSE050092R20) is part of ABB’s Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) solutions, designed for process automation and control in industries such as energy, chemical, oil & gas, power, and manufacturing. This module is specifically used to enhance the functionality and flexibility of ABB’s 800xA DCS platform, providing reliable, redundant, and scalable automation solutions.

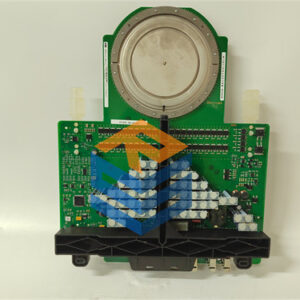

Product Name:

ABB PFEA113-20 (3BSE050092R20) DCS PLC Module

Product Description:

The ABB PFEA113-20 (3BSE050092R20) is a programmable logic controller (PLC) module designed for integration into ABB’s 800xA or other S800 I/O systems. It functions as part of ABB’s industrial control solution, ensuring efficient monitoring, control, and automation of various industrial processes. It is highly flexible and can be integrated into complex control systems in industries requiring high reliability, real-time control, and safe operation.

Key features include:

- Real-time process control for industrial operations, ensuring the control of variables like pressure, temperature, and flow.

- Redundancy and fault tolerance, ensuring high system availability and minimizing downtime.

- Scalability, supporting a variety of input/output configurations to meet diverse industrial requirements.

- Advanced diagnostic and predictive maintenance features, enhancing operational efficiency and reducing unplanned downtime.

The module is designed to meet the high demands of mission-critical processes while providing a user-friendly interface and integration with ABB’s other automation platforms.

Key Features:

-

High Availability and Redundancy:

- The PFEA113-20 module is designed with redundant configurations to ensure fault tolerance and continuous operation.

- Redundancy is particularly critical in industries like power plants, oil & gas, and chemical processing, where system downtime can lead to significant financial loss or safety hazards.

-

Modular Design and Scalability:

- The module’s design allows for scalable I/O configurations, making it suitable for small to large applications.

- It can easily be added to an existing ABB control system, providing flexibility in system expansion.

-

Advanced Diagnostics and Maintenance:

- Built-in diagnostics help monitor system health and predict failures before they happen, enabling predictive maintenance and reducing unplanned downtime.

- Comprehensive event logging and alarm management features allow for fast troubleshooting and performance optimization.

-

Real-Time Control and Monitoring:

- Ensures precise real-time control over various industrial processes and feedback loops, supporting applications in batch processing, continuous flow control, and safety-critical systems.

-

Communication Protocols:

- Supports Ethernet, Modbus, and other industrial communication standards, allowing seamless integration with other systems, sensors, and field devices.

- Full compatibility with the ABB 800xA platform ensures that this module can effectively communicate with other components in ABB’s ecosystem, providing a comprehensive automation solution.

-

Safety and Compliance:

- Meets SIL (Safety Integrity Level) standards, ensuring it can be safely integrated into safety-critical applications.

- The module complies with industrial safety regulations and EMC standards to ensure compatibility with a wide range of industrial environments.

Product Parameters and Specifications:

Electrical Specifications:

-

Input Voltage:

- Typically operates on 24V DC.

-

Power Consumption:

- Estimated between 10W to 30W (depending on the configuration and I/O load).

-

Operating Temperature Range:

- Typically operates in a range of 0°C to 60°C (32°F to 140°F).

-

Storage Temperature Range:

- Can be stored in the range of -40°C to 85°C (-40°F to 185°F).

-

Humidity:

- Operates in environments with 5% to 95% non-condensing humidity.

I/O Configuration:

- Digital Inputs/Outputs:

- Supports digital I/O, ideal for handling binary signals like switches and relays.

- Analog Inputs/Outputs:

- Supports 4-20mA analog signals or 0-10V inputs and outputs, useful for monitoring process variables like temperature, pressure, and flow.

- Specialized I/O:

- Depending on configuration, the module may also support high-speed counters, position sensors, or motion control I/O for advanced automation needs.

Communication and Networking:

- Ethernet Communication:

- The module supports Ethernet-based communication (typically Ethernet/IP or Modbus TCP), allowing seamless data exchange with other systems and control devices.

- Fieldbus Support:

- Compatible with Fieldbus protocols, such as Modbus RTU and Profibus, ensuring broad compatibility with field devices like sensors, actuators, and other industrial equipment.

- Redundant Communication:

- Redundant communication paths to ensure system reliability and prevent data loss or interruptions in case of network failure.

Safety and Compliance:

- SIL Rating:

- Typically rated for SIL 2 or SIL 3 compliance for use in safety-critical processes and applications.

- EMC Compliance:

- The module is designed to meet EMC standards, ensuring immunity to electromagnetic interference and compatibility with other industrial equipment in harsh environments.

Diagnostics and Maintenance:

-

Self-Diagnostics:

- Features built-in self-diagnostics for continuous monitoring of module health, ensuring early detection of faults.

-

Event Logging and Alarm Management:

- Provides comprehensive event logs and alarm management systems for troubleshooting and performance tuning.

-

Predictive Maintenance:

- Advanced predictive maintenance algorithms enable users to anticipate equipment failure, optimizing downtime and maintenance schedules.

Applications:

The ABB PFEA113-20 (3BSE050092R20) is used in industries that require high reliability and safety in process control, including:

- Power Generation: Control and monitoring of turbines, generators, and transformers.

- Oil & Gas: Automation of oil platforms, refineries, and pipeline monitoring systems.

- Chemical Processing: Control of reactors, distillation columns, and chemical blending processes.

- Water Treatment: Used for controlling water filtration, pumping, and distribution systems.

- Manufacturing: Supports automation in production lines, machine control, and assembly processes.

- Transportation: Used in rail, metro systems, and electrical substations for safety and control.

Conclusion:

The ABB PFEA113-20 (3BSE050092R20) module is a highly reliable, scalable, and flexible PLC/DCS solution suitable for a wide range of industrial automation applications. Its real-time control capabilities, redundancy features, advanced diagnostics, and communication options make it an ideal choice for industries such as energy, chemical, and manufacturing. With compliance to safety standards and integration with ABB’s 800xA system, it enhances operational efficiency while ensuring system uptime and minimizing maintenance costs.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922