الوصف

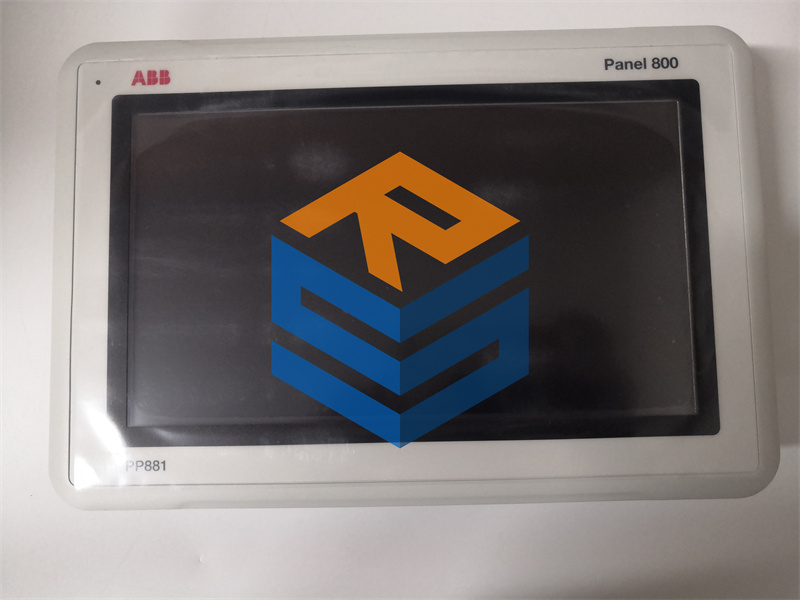

Product Name:

ABB PP881 3BSE092978R1 DCS PLC Module

Product Description:

The ABB PP881 3BSE092978R1 is a Distributed Control System (DCS) PLC Module designed for use in high-performance industrial control systems. This module is a key component of ABB’s 800xA control systems, providing a scalable and flexible solution for process automation, monitoring, and control in industries such as power generation, chemical, oil and gas, water treatment, and more.

The PP881 module is specifically designed for process automation, offering advanced functionalities like real-time control, redundant communication protocols, modular design, and flexibility in I/O configuration. Its advanced diagnostics and integration capabilities make it an essential part of industrial processes that require both high reliability and adaptability in complex operational environments.

Product Parameters:

- Model Number: PP881 3BSE092978R1

- Manufacturer: ABB

- Type: DCS PLC Module

- System Compatibility: ABB 800xA Distributed Control System

- Form Factor: Rack-mounted module (typically integrated in control cabinets)

- Power Supply Requirements: 24V DC

- Temperature Range: 0°C to +60°C (32°F to 140°F) for general industrial applications

- Humidity Range: 5% to 95% non-condensing

- Weight: Approx. 1.5 kg (varies based on configuration)

- Mounting Type: Rack-mounted (for ABB 800xA system integration)

- Redundancy: Dual communication ports for fault-tolerant operation (Hot standby redundancy)

- Input/Output Type: Configurable analog and digital I/O

- Communication Protocols:

- Modbus RTU/TCP

- Ethernet/IP

- Profibus DP

- OPC (for data exchange)

Product Specifications:

-

I/O Capabilities:

- Analog I/O:

- Analog Inputs: Configurable for signals such as 4-20mA, 0-10V, and others.

- Analog Outputs: For controlling actuators, valves, or motors.

- Digital I/O:

- Digital Inputs: For discrete sensors or switches (on/off status).

- Digital Outputs: For controlling relays, solenoids, and other actuators.

- Flexible I/O Configuration: Supports both analog and digital signals for various industrial applications.

- Analog I/O:

-

Control and Communication:

- The PP881 module integrates seamlessly with the ABB 800xA system.

- Supports Ethernet/IP, Modbus, and Profibus communication protocols to enable reliable and fast communication between various devices and control systems.

- Allows integration of both field devices (sensors, actuators) and supervisory systems (SCADA, HMI).

- Supports OPC (OLE for Process Control) for data exchange with other systems and applications.

-

Redundancy and Fault Tolerance:

- Supports dual communication ports for redundancy, ensuring reliable data transmission even in case of a failure in one communication channel.

- Redundant power supplies (for specific configurations) ensure continuous operation even during a power failure.

-

Real-time Control:

- The module provides real-time control and monitoring for industrial processes, enabling quick response times for changes in process variables.

- Time-critical functions such as motor control, valve control, and sensor readings can be handled with minimal latency.

-

Diagnostics and Monitoring:

- Integrated diagnostics provide continuous monitoring of the health and status of the module and connected devices.

- Features include self-diagnostics, status indicators, and error logs for quick troubleshooting.

- Continuous feedback ensures that system operators are alerted to potential issues before they result in system downtime.

-

Environment and Durability:

- Designed for operation in industrial environments, the module can withstand moderate levels of vibration and electromagnetic interference (EMI).

- The operating temperature range is 0°C to +60°C (32°F to 140°F), making it suitable for standard factory or process environments.

-

System Integration:

- Easily integrates with other ABB 800xA system components, including control panels, I/O modules, and HMI systems.

- Offers flexibility in configuring field devices, controllers, and actuators, allowing easy scaling of control systems based on operational needs.

-

Safety Features:

- The module adheres to safety standards to ensure the protection of both personnel and equipment.

- Implements safe interlocks and control sequences for critical processes.

Key Features:

- Modular I/O Configuration: Flexible analog and digital inputs/outputs that can be configured as per process needs.

- Multiple Communication Protocols: Supports Modbus, Profibus, Ethernet/IP, and OPC, allowing integration with a variety of field devices and controllers.

- Redundancy: Dual communication channels and optional redundant power supplies provide high availability and reliability.

- Real-time Control: Ensures fast, reliable processing of input data and quick execution of control commands.

- Diagnostic Features: Integrated diagnostic tools that monitor system health and help reduce downtime.

- Environmental Durability: Designed to operate in harsh industrial environments with high EMI tolerance.

Applications:

The ABB PP881 3BSE092978R1 DCS PLC Module is widely used in industries requiring distributed process control and automation:

-

Oil and Gas:

- For real-time control of pumps, compressors, flow meters, and other critical devices in upstream and downstream oil and gas operations.

- Enables secure pipeline monitoring, pressure control, and emergency shutdown systems.

-

Power Generation:

- Used in boiler control, turbine control, and generator synchronization for electric power plants.

- Real-time monitoring of temperature, pressure, and vibration to ensure plant safety and efficiency.

-

Chemical Industry:

- Automation and control of chemical reactors, mixing systems, conveyor belts, and dosing stations.

- Precise control of reaction times, temperature and chemical composition to ensure product quality.

-

Water Treatment:

- Control of pumps, valves, filters, and chemical dosing in water purification and wastewater treatment plants.

- Monitors water quality and optimizes the use of resources, ensuring safe and efficient water management.

-

Manufacturing:

- Integration into automated production lines, controlling systems like robotic arms, conveyor belts, and assembly systems.

- Facilitates quality control, tracking of production processes, and maintenance management.

Conclusion:

The ABB PP881 3BSE092978R1 DCS PLC Module is a versatile and highly reliable solution for industrial process automation and control. It integrates seamlessly with the ABB 800xA system and provides extensive I/O capabilities, real-time control, redundancy, and flexible communication protocols. With its advanced diagnostic features and rugged design, the PP881 module is ideal for industries like oil and gas, power generation, chemical processing, and water treatment, where uptime, reliability, and scalability are crucial to operational success.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922