الوصف

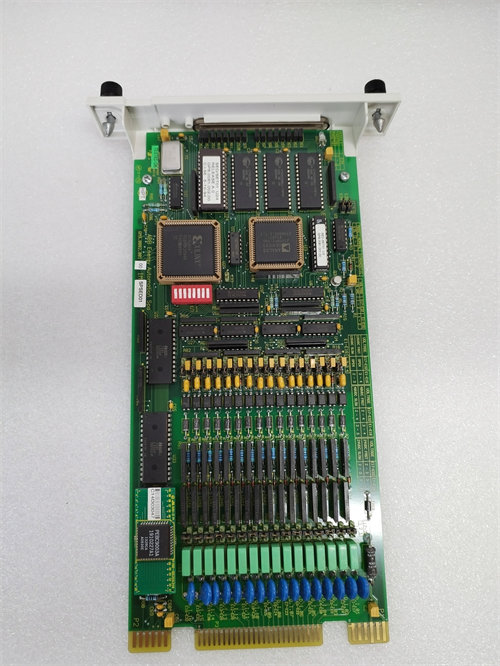

The ABB SPSED01 is part of the ABB System 800xA distributed control system (DCS) platform, and it is designed for process control and automation in industrial settings. This module plays an essential role in enhancing system communication and functionality. Here’s a detailed overview of the ABB SPSED01 DCS PLC module.

Product Name:

- ABB SPSED01 – System 800xA I/O and Controller Module

Product Description:

The ABB SPSED01 module is part of the System 800xA Distributed Control System (DCS), designed to integrate into complex process automation and control applications. It is often used in industries such as oil & gas, chemical processing, power generation, and water treatment.

This module acts as a communication bridge between various I/O devices, sensors, and field equipment, enabling efficient data processing and control functions. The SPSED01 supports a wide range of communication protocols and is equipped with the necessary processing power to manage real-time control functions, contributing to the seamless operation of automated systems. It integrates well within the ABB 800xA environment, providing enhanced flexibility and reliability for critical applications.

Key Features:

- High-Performance Communication: Facilitates high-speed data transfer between controllers, field devices, and I/O systems.

- Real-Time Control: Ensures that process operations are controlled and monitored in real-time with minimal latency.

- Modular Design: Supports system expansion by adding more I/O devices or modules, enhancing scalability.

- Versatile I/O: Allows connection to a wide variety of input and output devices, including both analog and digital I/Os.

- Reliability & Redundancy: Features built-in redundancy for critical systems to ensure maximum uptime and minimal disruptions.

- Advanced Diagnostics: Equipped with diagnostic tools for fault detection, system health monitoring, and easy troubleshooting.

Product Parameters & Specifications:

General Information:

- Module Type: Controller and I/O Module for ABB System 800xA

- Application Area: Used in process control, automation, and industrial control systems.

- Series: 800xA DCS (Distributed Control System).

- Processor Type: Advanced processor capable of handling both real-time control and communication functions.

Electrical Specifications:

- Input Voltage: Typically operates on 24V DC (this can depend on specific configuration and system integration).

- Power Consumption: Usually, the power consumption is relatively low, with an estimated range between 15W – 25W depending on configuration.

- Current Consumption: Around 800mA at 24V DC.

I/O Expansion and Capability:

- Digital I/O: Can handle a large number of digital I/O points (ranging from hundreds to over a thousand, depending on the configuration).

- Analog I/O: Supports analog I/O for precise measurement and control, typically 4-20mA, 0-10V.

- High-Speed I/O: Designed to accommodate high-speed digital I/O for applications requiring quick data processing, such as motion control and real-time process monitoring.

Communication Protocols:

- Ethernet/IP: Provides communication over Ethernet for high-speed data transfer and integration with other networked devices.

- Modbus TCP/IP: For communication with third-party devices and systems.

- PROFIBUS: Facilitates communication with field devices over PROFIBUS DP and PROFIBUS PA networks.

- DeviceNet: For integrating with field devices and remote I/O modules.

- Serial Communication: Supports RS232/RS485 for legacy devices and non-networked systems.

Real-Time Control and Processing:

- Real-Time Control: Ensures that critical operations, such as process monitoring and control, are carried out in real-time with minimum delays.

- Execution Time: Typically optimized for low latency, processing tasks in milliseconds for time-sensitive applications.

- Data Storage: Includes support for non-volatile memory to store configurations, control programs, and process data.

Software and Programming:

- Programming Environment: Fully compatible with ABB 800xA Engineering, a comprehensive suite for system configuration and management. It also integrates with AC800M controllers for advanced automation.

- Languages Supported: IEC 61131-3 programming languages, including Ladder Logic (LD), Structured Text (ST), Function Block Diagram (FBD), and Sequential Function Chart (SFC).

Diagnostics & Fault Detection:

- Diagnostic Tools: Built-in diagnostic tools that help in detecting system faults, hardware failures, and communication errors.

- Status LEDs: Includes LED indicators to display system status, operational health, and communication status.

- Redundancy Support: Features optional redundant configurations for mission-critical applications, ensuring reliability and fault tolerance.

- Remote Monitoring: Integrated tools for monitoring system performance remotely via ABB’s System 800xA interface.

Environmental Specifications:

- Operating Temperature Range: Typically 0°C to 60°C (32°F to 140°F).

- Storage Temperature Range: Typically -20°C to 70°C (-4°F to 158°F).

- Humidity: Designed for operation in environments with 5% to 95% non-condensing humidity.

- Vibration Resistance: Designed to withstand the typical vibrations encountered in industrial environments.

Physical Specifications:

- Module Dimensions: Approximately 200mm x 140mm x 50mm (W x H x D), depending on the exact model and configuration.

- Weight: Around 1-2 kg (2.2-4.4 lbs) depending on the specific configuration and I/O capacity.

Compliance & Certification:

- CE Marked: Compliant with European Union safety and environmental standards.

- UL Listed: Certified for use in North America under UL safety standards.

- RoHS Compliant: Meets RoHS (Restriction of Hazardous Substances) regulations for environmental safety.

- EMC Compliance: Designed to meet industrial electromagnetic compatibility (EMC) standards.

Key Features & Benefits:

- Modular and Scalable: Can be expanded to meet growing process control needs with a flexible and modular design.

- High Availability: Redundancy and fault-tolerant design ensures high availability and system reliability for critical operations.

- Real-Time Performance: Designed for high-speed, low-latency control and monitoring of real-time processes.

- Versatile Communication Options: Multiple communication protocols including Ethernet, Modbus, PROFIBUS, and DeviceNet provide flexibility in connecting various devices and systems.

- Enhanced Diagnostics: Offers advanced diagnostic capabilities that support efficient troubleshooting and maintenance.

Applications:

- Process Automation: Ideal for industries such as oil & gas, chemical manufacturing, and power plants, where continuous, reliable process control is crucial.

- Water and Wastewater Treatment: Used in water treatment plants, managing real-time control of pumps, valves, and other critical infrastructure.

- Energy and Utilities: Plays a key role in managing complex processes in the energy and utilities sectors, including power generation, distribution, and transmission.

- Building Management Systems (BMS): Used in automation for HVAC, lighting, and other building systems, ensuring efficient and sustainable operations.

Conclusion:

The ABB SPSED01 is an advanced and highly reliable DCS module that enables real-time control and seamless communication across various industrial systems. Its flexibility, performance, and scalability make it ideal for complex automation tasks in industries requiring high levels of control, precision, and reliability. Integrating the SPSED01 into the ABB 800xA DCS platform ensures optimal process efficiency, safety, and system uptime.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922