الوصف

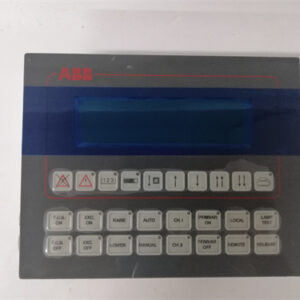

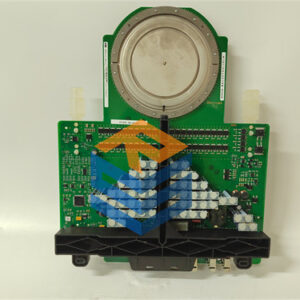

The ABB UAD155A0111 (3BHE029110R0111) is a Distributed Control System (DCS) PLC module used primarily in industrial automation and process control applications. It is part of ABB’s 800xA platform, which is widely used in industries such as oil & gas, power generation, chemical processing, and other process control sectors.

Here is a detailed breakdown of the product:

Product Name:

ABB UAD155A0111 (3BHE029110R0111) DCS PLC Module

Product Description:

The ABB UAD155A0111 is a Distributed Control System (DCS) PLC module designed to provide high-performance process control and automation for industrial environments. It integrates seamlessly into the ABB 800xA control system, offering reliable, real-time control of industrial processes, ensuring efficient, safe, and smooth operation.

This module is specifically engineered to handle complex processes and features redundant architecture, flexible I/O options, and advanced diagnostic capabilities. It’s suitable for industries requiring high availability, such as power plants, petrochemical facilities, mining, and food & beverage industries.

Product Parameters & Specifications:

Model:

- ABB UAD155A0111 (3BHE029110R0111)

Module Type:

- DCS PLC Module (for the ABB 800xA Distributed Control System).

Type of Control:

- Process Control module for integration with ABB’s 800xA system.

Input/Output Configuration:

- Digital Inputs/Outputs: Supports multiple types of digital I/O, suitable for monitoring and controlling discrete events in an industrial environment.

- Analog Inputs/Outputs: Provides precise control and monitoring of continuous processes that require analog signals (such as temperature, pressure, or flow).

Communication Interfaces:

- Ethernet/IP: High-speed communication standard for efficient data exchange between the module and other devices within the control system.

- Modbus TCP/IP: For communication with field devices and remote I/O.

- Profibus DP: Industry-standard communication protocol for seamless integration with field devices like sensors and actuators.

- Redundant Communication: Ensures reliable operation in mission-critical applications where communication failure could lead to system downtime.

Power Supply:

- 24V DC nominal voltage to operate the system and modules.

- Redundant Power Supply: Designed with redundant power options for increased system reliability.

Redundancy:

- Hot-swap capability for easy replacement of faulty modules without taking the system offline.

- Redundant system architecture for critical components to minimize downtime and maintain continuous control.

Operating Temperature:

- Range: -20°C to +60°C (-4°F to +140°F).

- Storage Range: -40°C to +85°C (-40°F to +185°F).

Dimensions:

- Typical Dimensions: 6 x 4 x 1.5 inches (152 x 102 x 38 mm), though the exact size may vary depending on configuration.

Weight:

- Approximate weight: 1-2 kg, depending on configuration.

Environmental Protection:

- IP20 rating, designed for use in indoor environments with controlled temperature and humidity.

Safety Certifications:

- Meets relevant international standards for control systems in industrial and process automation, such as ISO 9001 (Quality Management), IEC 61508 (Functional Safety), and IEC 61511 (Process Safety).

Processing Power:

- Advanced Processor: Capable of real-time processing and handling large volumes of data for industrial applications.

- Multiple Processing Units: Allows for parallel processing in multi-threaded operations, ensuring quick response times for process control.

Key Features & Benefits:

-

High-Performance Control:

The UAD155A0111 module is designed to provide high-speed data processing, allowing for fast, real-time control of industrial processes. -

Flexibility:

The module supports a wide range of I/O options and is highly adaptable for use in various industries with differing needs. -

Redundancy for High Availability:

With features like redundant communication paths and hot-swappable modules, this module is ideal for use in applications where system uptime is critical. -

Integrated Diagnostics:

Real-time diagnostics and status monitoring help operators to identify faults and inefficiencies before they lead to system failures, reducing downtime and improving maintenance processes. -

Scalability:

The ABB 800xA platform is scalable, so this module can be used as part of a small or large system and can grow alongside the industrial application. -

Industry Standard Protocols:

Supports communication protocols like Modbus TCP/IP, Ethernet/IP, and Profibus DP, ensuring easy integration with existing systems and devices. -

Safety Compliance:

Meets IEC 61508 and IEC 61511 for functional safety, making it suitable for use in critical, safety-sensitive environments such as chemical plants, power stations, and oil refineries.

Applications & Use Cases:

The ABB UAD155A0111 DCS PLC module is designed for use in industries where high performance, flexibility, and safety are required:

- Power Generation: The module can control and monitor nuclear, coal, gas, and hydroelectric plants, ensuring stable power generation.

- Oil & Gas: Ideal for offshore drilling, refining processes, and oil transportation, where safety and real-time control are paramount.

- Chemical Processing: Used in petrochemical plants for precise monitoring and control of chemical reactions and plant processes.

- Mining: Handles complex control processes for mining operations, including automation of extraction, transportation, and processing systems.

- Food & Beverage: For controlling production lines, packaging, and quality assurance processes in food manufacturing.

Comparison with Other PLC Modules:

When compared to other PLC modules like Siemens S7 or Schneider Electric Modicon, the ABB UAD155A0111 excels in its integrated diagnostic capabilities and redundant architecture, making it particularly suitable for high-risk environments that require continuous, uninterrupted control. Additionally, its flexibility and scalability with the ABB 800xA system allow it to be adapted for both small-scale operations and large industrial systems.

Recommendation for Selection:

- Mission-Critical Applications: The UAD155A0111 is highly recommended for industries where reliability and high availability are crucial, such as power generation, oil & gas, and chemical processing.

- Real-Time Process Control: For applications that require fast, accurate control of continuous processes, this module’s high-performance capabilities make it an ideal choice.

- Integrated System Needs: If you are already using the ABB 800xA platform, this module is an excellent choice for integration, as it ensures smooth communication and interoperability across the entire system.

Let me know if you need more details or specific comparisons to other models!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922