الوصف

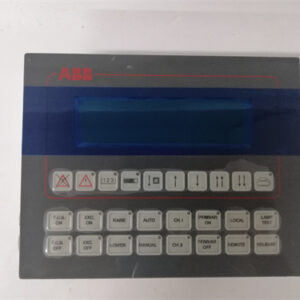

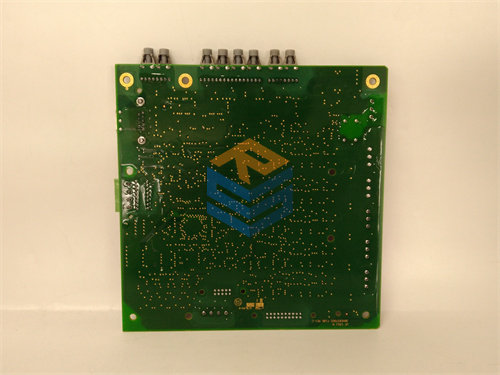

ABB UFC911B106 3BHE037864R0106 DCS PLC Module

Product Name:

ABB UFC911B106 3BHE037864R0106 DCS PLC Module

Product Description:

The ABB UFC911B106 3BHE037864R0106 is a Universal Function Control (UFC) module designed for integration within ABB’s Distributed Control System (DCS) and Programmable Logic Controller (PLC) environments. This module is typically used in complex industrial automation systems, providing robust control, monitoring, and diagnostics for a wide range of applications. It is designed to interface with various I/O signals, process control loops, and support complex control strategies in industries such as power generation, oil and gas, chemical plants, and water treatment facilities.

The UFC911B106 module can handle both analog and digital signals, offering versatile functionality to meet various process control requirements. It is a reliable module that offers high performance, diagnostic capabilities, and seamless integration with ABB’s broader control systems.

Key Features:

- High Versatility: Supports both analog and digital I/O signals.

- Modular Design: Part of ABB’s modular control system, making it scalable and adaptable to various control needs.

- Diagnostics and Monitoring: Equipped with advanced diagnostics for real-time system health monitoring, helping to detect faults early and minimize downtime.

- Reliable Performance: Offers high stability and accuracy, ensuring optimal operation of the control system.

- Seamless Integration: Works seamlessly with ABB’s DCS and PLC systems, ensuring smooth system communication and process control.

Product Parameters:

- Model Number: UFC911B106

- Part Number: 3BHE037864R0106

- Type: Universal Function Control Module

- System Compatibility: ABB DCS and PLC systems

- Input Types: Analog (e.g., 4-20mA, 0-10V) and Digital (e.g., ON/OFF, pulse signals)

- Output Types: Analog (e.g., 4-20mA, 0-10V) and Digital (e.g., relay or transistor outputs)

- Mounting: Typically mounted on a DIN rail or integrated into the DCS/PLC control panel.

- Power Supply: Typically powered by a 24V DC control system supply.

- Operating Environment: Designed for harsh industrial environments with temperature, humidity, and vibration resistance.

Product Specifications:

-

Communication Interface:

- Protocol: Common ABB communication protocols such as PROFIBUS, Modbus, or Ethernet/IP depending on the system configuration.

- Bus Type: Integrated into ABB’s DCS or PLC backplane for high-speed communication and ease of system expansion.

- Connectors: Typically uses screw terminals or spring-loaded connectors for field wiring.

-

Input/Output:

- Input Types:

- Analog Inputs: 4-20 mA, 0-10V, or other industry-standard analog signals.

- Digital Inputs: ON/OFF switches, pulse signals, or binary I/O.

- Output Types:

- Analog Outputs: 4-20 mA, 0-10V for precise control signals.

- Digital Outputs: Relay or transistor outputs for controlling external devices (e.g., actuators, motors).

- Signal Conditioning: Includes features like filtering and scaling to ensure high accuracy in signal processing.

- Input Types:

-

Performance:

- Sampling Rate: High-speed sampling with real-time feedback, typically between 10 Hz and 1 kHz depending on system configuration.

- Resolution: Analog input/output resolution typically ranges from 12-bit to 16-bit for precise control.

- Accuracy: High accuracy typically around ±0.1% of full scale for analog signals.

- Response Time: Typically less than 100ms for digital I/O.

-

Environmental Conditions:

- Operating Temperature: Typically -20°C to +60°C, depending on installation conditions.

- Storage Temperature: -40°C to +85°C for safe handling and storage.

- Humidity: 5% to 95% non-condensing.

- Vibration Resistance: Designed for typical industrial vibration environments (up to 2g).

- Shock Resistance: Built to meet industrial shock standards for durable operation.

-

Power Requirements:

- Nominal Voltage: Typically 24V DC for control and communication.

- Power Consumption: Typically around 5-15W depending on the configuration and number of I/O points.

- Current Draw: Depends on the number of active I/O channels; typically ranges from 100mA to 500mA.

-

Physical Dimensions:

- Size: Compact design for easy integration into control panels and rack systems.

- Weight: Typically 0.5-1.5kg, depending on configuration and number of I/O channels.

-

Signal Processing and Protection:

- Signal Filtering: Features built-in signal filtering for noise reduction in harsh industrial environments.

- Overvoltage Protection: Includes protection circuits to shield the module from electrical surges and spikes.

- Galvanic Isolation: Provides isolation between field devices and the controller to prevent electrical faults and noise interference.

-

Diagnostics and Fault Detection:

- LED Indicators: Multiple status LEDs for real-time diagnostics, indicating the health of the module and any faults or communication issues.

- Self-Diagnostics: Built-in diagnostics that monitor the operational status of the module, detecting issues like communication errors, power failures, and signal irregularities.

- Alarm Outputs: Configurable alarm outputs to alert operators of faults or abnormal operating conditions.

-

Compliance and Certifications:

- CE Certification: Complies with European Union safety and environmental standards.

- UL Listed: UL certification for safety and operation in North America.

- RoHS Compliance: Meets the RoHS (Restriction of Hazardous Substances) standard.

- Ex Certification: Some configurations may offer explosion-proof or ATEX certification for hazardous environments.

Applications:

- Power Generation: Used for controlling and monitoring power plant equipment, such as turbines, generators, and boilers.

- Oil & Gas: Applied in upstream and downstream operations for process control, monitoring, and safety systems.

- Chemical Plants: Essential for controlling chemical processes, reactors, and temperature-sensitive operations.

- Water Treatment: Employed in water and wastewater treatment plants for controlling pumps, filtration systems, and chemical dosing.

- Industrial Automation: Provides versatile control and monitoring for automated manufacturing and processing systems.

Additional Features:

- Advanced Control Algorithms: Includes support for complex control algorithms, such as PID control, cascade control, and multi-variable control, to optimize industrial processes.

- Modular Design: The UFC911B106 is part of a modular system, enabling easy expansion and adaptation to different control needs.

- User-Friendly Interface: Equipped with software tools that facilitate easy configuration and diagnostics, often with integrated graphical user interfaces (GUIs) for user interaction.

- Scalability: Easily expandable to accommodate growing control system requirements with additional modules or I/O points.

The ABB UFC911B106 3BHE037864R0106 is a versatile and highly reliable module that ensures the seamless operation of complex control systems in industries requiring precise, real-time data monitoring and management. Its integration with ABB’s DCS and PLC systems allows for superior control of industrial processes, enhancing operational efficiency and safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922