الوصف

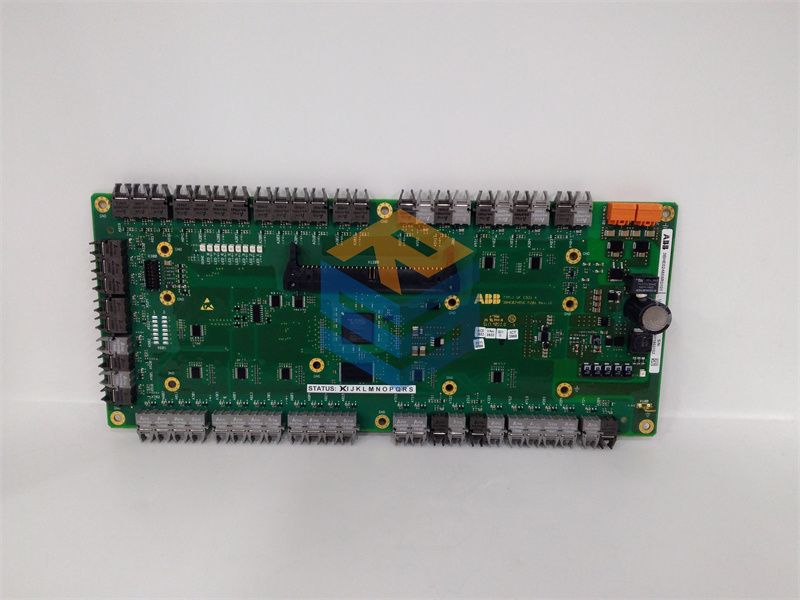

Here’s the information for the ABB UFC921A 3BHE024856P201 DCS PLC Module:

Product Name

ABB UFC921A 3BHE024856P201 DCS PLC Module

Product Description

The ABB UFC921A 3BHE024856P201 is a sophisticated Distributed Control System (DCS) module designed for industrial automation applications requiring high reliability, real-time control, and seamless integration. It is part of ABB’s lineup of advanced PLC modules, tailored for use in demanding environments across various industries.

Product Parameters & Specifications

- Model: ABB UFC921A 3BHE024856P201

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) Module

- Processor:

- High-performance processor for fast data processing and control algorithms.

- Memory:

- RAM: 512MB

- Flash Memory: 256MB (expandable)

- Power Supply:

- Nominal Voltage: 24V DC

- Operating Voltage Range: 10V to 30V DC

- Communication Protocols:

- Supports multiple protocols including Modbus TCP/RTU, Profibus DP, Ethernet/IP, and proprietary protocols for seamless integration with various industrial systems.

- I/O Configuration:

- Digital Inputs: 32 channels

- Digital Outputs: 32 channels

- Analog Inputs: 16 channels

- Analog Outputs: 16 channels

- Redundancy:

- Dual-processor configuration with redundant power supplies for enhanced reliability and fault tolerance.

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +85°C

- Humidity: 5% to 95%, non-condensing

- Mounting Type: Rack-mounted (19” form factor)

- Dimensions:

- Height: 3U (standard rack size)

- Width: 19 inches (standard form factor)

- Depth: Varies depending on configuration

- Weight: Approximately 3 kg (varies with configuration)

- Safety and Compliance:

- CE Mark

- UL Certified

- Suitable for use in hazardous environments (depending on configuration)

- Environmental Rating: Designed to withstand harsh industrial environments with protection against dust, moisture, and temperature variations.

Key Features

- Real-Time Control:

- Ensures precise and timely control of industrial processes, essential for critical applications in power generation, oil & gas, chemical processing, and manufacturing.

- Redundancy and High Availability:

- Dual-processor and redundant power supplies ensure continuous operation even in the event of component failure, minimizing downtime.

- Advanced Diagnostics:

- Provides comprehensive diagnostic capabilities for proactive maintenance and troubleshooting.

- Modular and Scalable Design:

- Allows flexibility in system configuration and scalability to meet evolving automation needs.

- Wide Range of Communication Protocols:

- Supports industry-standard communication protocols for seamless integration into existing control systems.

- Robust Environmental Specifications:

- Designed to operate reliably in challenging industrial environments with wide temperature and humidity ranges.

- Safety and Compliance:

- Meets international safety standards and certifications, suitable for deployment in regulated industries.

Applications and Use Cases

The ABB UFC921A 3BHE024856P201 DCS PLC Module is ideal for applications including:

- Power Generation: Control and monitoring of turbines, generators, and auxiliary systems in power plants.

- Oil & Gas: Management of equipment such as pumps, compressors, and valves in oil and gas exploration, refining, and distribution.

- Chemical and Petrochemical Plants: Precise control of reactors, distillation columns, and chemical processes.

- Manufacturing: Automation of production lines, robotics, conveyors, and other industrial machinery.

- Water Treatment: Supervision of pumps, filtration systems, and chemical dosing in water and wastewater treatment facilities.

This module offers robust performance, reliability, and flexibility to meet the demanding requirements of modern industrial automation. If you need more details or have further questions, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922