الوصف

Product Name:

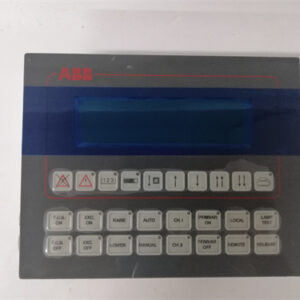

ABB XDD501A101 DCS/PLC Module

Product Description:

The ABB XDD501A101 is a Distributed Control System (DCS) module that plays a pivotal role in the automation of complex industrial systems. It is part of ABB’s 800xA and Freelance control systems, offering precise and scalable control for a wide range of industrial applications. The module is designed to work seamlessly within Distributed Control Systems (DCS) or Programmable Logic Controllers (PLC), providing high-level performance and functionality.

This module is tailored for industries like oil & gas, chemical processing, power generation, water treatment, and other sectors where reliable, robust, and flexible control systems are critical. It supports a variety of protocols, enabling easy integration into existing systems and facilitating communication across different hardware.

The XDD501A101 module is ideal for managing real-time data, monitoring operations, and controlling machinery or processes in environments requiring continuous and precise monitoring.

Product Parameters & Specifications:

Module Type:

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC)

- System: Compatible with ABB’s 800xA and Freelance control systems.

Input/Output Specifications:

- Digital Inputs: Supports digital I/O for discrete signals from field devices (e.g., sensors, switches).

- Digital Outputs: Provides digital outputs to control actuators, relays, or other systems.

- Analog Inputs: Handles analog signals (e.g., temperature, pressure, flow) for continuous monitoring and control.

- Analog Outputs: Provides analog control signals to systems such as valves, motor drives, or variable-speed drives.

Communication Protocols:

- Modbus RTU: Allows communication with other industrial devices and systems using Modbus RTU protocol.

- Profibus DP: Supports Profibus DP for fast data exchange and communication with other automation devices.

- Ethernet/IP: Ethernet-based communication for real-time control, monitoring, and integration.

- HART Protocol: For communication with smart field devices, enabling easy access to device diagnostics and data.

Power Supply:

- Operating Voltage: Typically operates on 24 V DC or 48 V DC depending on the system configuration.

- Power Consumption: The module’s power consumption will vary depending on the specific configuration and connected devices.

Control and Performance:

- Real-Time Control: Provides precise real-time control for industrial applications, ensuring operations are monitored and controlled without delays.

- Data Processing: Supports high-speed data processing for accurate decision-making and process adjustments.

- Response Time: Fast response times for critical applications requiring rapid action based on input changes.

Environmental Specifications:

- Operating Temperature: Typically operates within 0°C to 55°C (32°F to 131°F), ensuring stable performance in a wide range of industrial environments.

- Storage Temperature: -20°C to 70°C (-4°F to 158°F) for safe storage without damage.

- Humidity: Typically supports 5% to 95% RH, non-condensing, allowing it to function well in both dry and moderately humid environments.

- Vibration and Shock Resistance: Designed to be resilient to vibration and shock, meeting industrial standards for robustness in manufacturing plants or industrial environments.

Mounting and Integration:

- Mounting Type: The module can be rack-mounted or installed within control cabinets, designed for ease of integration into standard industrial racks.

- Slot Configuration: Compatible with ABB’s modular control systems and designed for easy slot-based installation.

Redundancy and Reliability:

- Redundant Power Supplies: Supports redundant power supply options to increase system uptime and ensure reliability in critical applications.

- Fail-Safe Operation: Integrated fail-safe features to maintain control during unexpected failures, preventing system downtime and safety issues.

Safety and Compliance:

- Safety Features: The module supports integration with safety controllers and can be used to implement SIL-rated (Safety Integrity Level) functions in line with IEC 61508 standards.

- Certification: Meets major industry standards, such as CE, UL, CSA, and ATEX for hazardous area environments.

Software and Programming:

- ABB 800xA System Integration: Fully compatible with ABB’s 800xA platform for centralized control, monitoring, and system integration.

- Freelance Configuration Software: For smaller applications or modular control needs, the Freelance system provides simple configuration and programming.

- Engineering Tools: Supports integration with ABB’s comprehensive suite of engineering tools for system configuration, diagnostics, and monitoring.

Dimensions and Physical Characteristics:

- Module Dimensions: Typically 12-15 cm (height), 7-10 cm (width), and 15-20 cm (depth) depending on the variant.

- Weight: The module weight typically ranges from 1.5 to 3 kg, depending on the exact configuration.

Diagnostics and Monitoring:

- Diagnostic LEDs: The module includes built-in LED indicators for monitoring the operational status, faults, and communication states.

- Alarms and Alerts: Supports generation of alerts and alarms for fault conditions, ensuring operators are notified of any critical issues.

Key Features & Benefits:

-

Flexible Integration:

- The XDD501A101 integrates seamlessly with other ABB automation systems like 800xA or Freelance, offering flexibility for both large-scale and smaller industrial applications.

-

High-Performance Control:

- Supports high-speed, real-time control, essential for processes where delay and performance issues cannot be tolerated.

-

Advanced Communication Protocols:

- The wide array of communication protocols, including Modbus, Profibus, and Ethernet/IP, ensures compatibility with a broad range of devices and systems.

-

Modular and Scalable:

- The modular nature of the ABB 800xA or Freelance systems means the XDD501A101 can easily scale up or down based on project size or future expansion needs.

-

Safety and Compliance:

- The integration of safety functions and certifications like SIL (Safety Integrity Level) makes it an excellent choice for industries with stringent safety standards.

-

Reliability:

- With redundant power supplies and fail-safe features, the module ensures high availability and minimal downtime, making it suitable for mission-critical industrial applications.

Applications & Use Cases:

- Oil & Gas: For managing process control in refineries, petrochemical plants, or offshore platforms.

- Chemical Processing: Used for controlling complex chemical reactions, monitoring safety conditions, and managing production lines.

- Power Generation: Supports control and monitoring of power plants, including turbines, generators, and electrical distribution systems.

- Water Treatment: Ideal for municipal or industrial water treatment plants, offering control over pumps, valves, and filtration systems.

- Manufacturing: Used for controlling production lines, robotic systems, and assembly operations in automotive, food & beverage, and consumer goods industries.

Conclusion & Recommendation:

The ABB XDD501A101 DCS/PLC module is a powerful, flexible, and reliable solution for automation and control in demanding industrial environments. With its robust feature set, advanced communication protocols, and support for high-speed real-time control, it is ideal for industries where precision, safety, and reliability are paramount.

Let me know if you need any more details or a comparison with other similar products!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922