الوصف

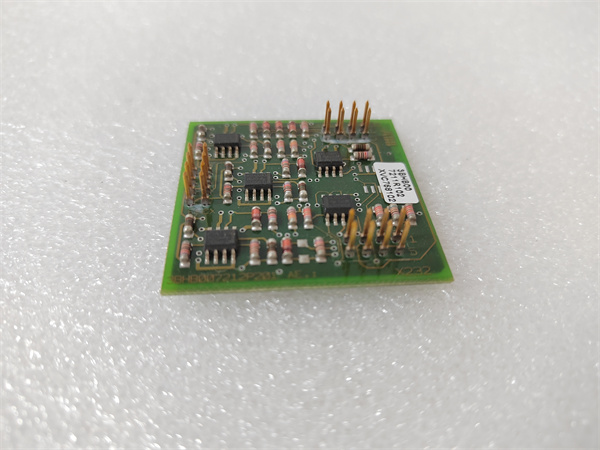

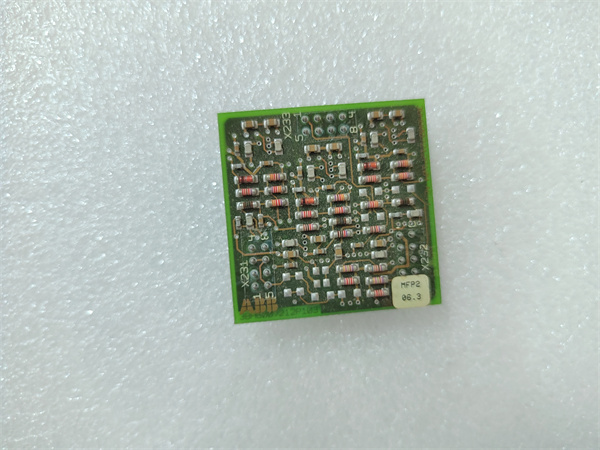

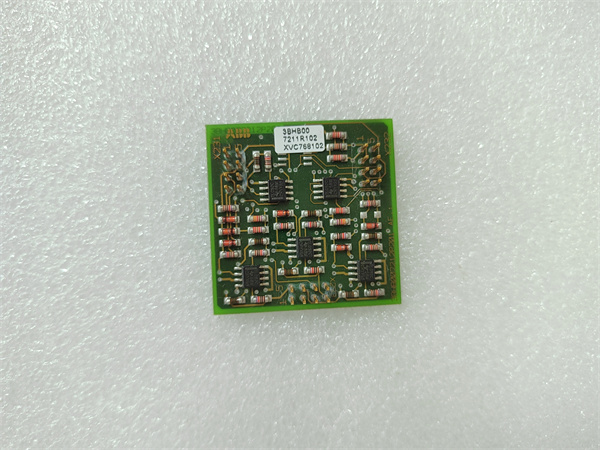

ABB XVC768116 3BHB007211R116 DCS PLC Module

Product Name:

ABB XVC768116 3BHB007211R116 DCS PLC Module

Product Description:

The ABB XVC768116 3BHB007211R116 is a Distributed Control System (DCS) PLC module designed to be used in advanced automation and process control applications. This module is part of ABB’s range of control systems, which are known for their flexibility, reliability, and scalability. The XVC768116 module integrates seamlessly with other ABB control systems, providing superior performance for mission-critical applications in industries such as power generation, chemical processing, oil & gas, and manufacturing.

It supports a wide variety of I/O configurations, high-speed data processing, real-time control, and industrial communication protocols. The module is engineered for reliability and redundancy, ensuring high availability and continuous operation, even in harsh industrial environments. Its compact design, ease of integration, and advanced diagnostic capabilities make it an ideal solution for industrial automation and control.

Product Parameters:

-

Model Number:

XVC768116 3BHB007211R116 -

Manufacturer:

ABB (Asea Brown Boveri) -

Type:

DCS PLC Module (Distributed Control System and Programmable Logic Controller) -

System Compatibility:

Fully compatible with ABB’s XVC Series and other ABB DCS systems. This module can be integrated with multiple automation systems and is widely used in industries like power generation, chemical, oil & gas, and water treatment. -

Power Supply:

- Nominal Voltage: 24V DC

- Power Consumption: Depends on the configuration and connected I/O modules.

-

Operating Temperature:

- Range: -40°C to +70°C (designed for industrial environments)

-

Weight:

- Approximately 1.2 – 2.5 kg, depending on the configuration.

-

Environmental Conditions:

- Humidity: Up to 95% (non-condensing)

- Vibration Resistance: Meets the typical industrial standards for vibration tolerance in control and automation systems.

Specifications:

-

I/O Channels:

- Digital Inputs (DI): Configurable up to 32 channels

- Digital Outputs (DO): Configurable up to 32 channels

- Analog Inputs (AI): 8-16 channels for real-time data collection

- Analog Outputs (AO): 8-16 channels for controlling actuators, valves, or other devices.

-

Processor:

- Real-Time Control: The module is capable of processing data in real time for the precise and fast control of industrial processes.

- Control Algorithms: Supports PID control loops, advanced process control, cascade control, and logic-based controls.

-

Memory:

- The module includes sufficient onboard memory to store control logic, I/O mappings, and diagnostic data for continuous system operation.

-

Communication Protocols:

- Ethernet/IP: High-speed communication for real-time data transfer between modules and external systems.

- Profibus: For integration with field devices and sensors.

- Modbus RTU/TCP: Popular for communication with remote devices, sensors, and actuators.

- HART Protocol: For smart field devices, including sensors and transmitters.

-

System Integration:

- Integrates smoothly with ABB’s XVC DCS systems and other ABB automation solutions, allowing for efficient control and management of large, complex processes.

-

Diagnostics and Monitoring:

- The module provides comprehensive self-diagnostics for early detection of faults or performance degradation.

- Event logging: Logs critical system events and alarms to facilitate troubleshooting and minimize downtime.

-

Safety Features:

- Supports SIL 2/SIL 3 safety standards, making it suitable for safety-critical systems such as those used in chemical plants, oil rigs, and power plants.

- Redundancy features for critical system components (such as power supply and communication paths) ensure operational continuity.

-

Redundancy:

- The module offers redundant configurations for both communication and power supply, ensuring fail-safe operation in case of component failure.

-

Expansion and Flexibility:

- The system allows for easy expansion with additional I/O modules or other control system components, offering flexibility to scale as required.

-

Mounting and Form Factor:

- The module is designed for rack-mounting in industrial cabinets and can be easily installed in control panels.

- It is equipped with LED indicators for quick status checks and troubleshooting.

Key Features:

-

Real-Time Process Control:

The module excels at real-time data processing and control, ensuring precise regulation of industrial processes, making it suitable for fast-paced and time-sensitive applications. -

Flexible I/O Configuration:

The XVC768116 module offers a wide variety of I/O configurations, adaptable to multiple control loops, making it suitable for diverse industrial applications. -

Advanced Diagnostics and Monitoring:

Comprehensive self-diagnostics, event logging, and performance monitoring for easy troubleshooting and quick identification of system issues. -

High Reliability with Redundancy:

Designed for high-reliability applications, the module supports redundant power supplies, communication paths, and other critical system components. -

Scalable System:

Easily integrated into ABB XVC Series and other ABB DCS systems, and highly expandable for future growth, ensuring long-term usability. -

Support for Multiple Communication Protocols:

Offers seamless communication with devices and systems using Ethernet/IP, Modbus, Profibus, and HART, enabling interoperability with a broad range of field devices. -

Compliance with Safety Standards:

The module supports SIL 2/SIL 3 safety standards, ensuring it is suitable for safety-critical applications, such as in the oil & gas, chemical, and power industries. -

Compact Design for Easy Integration:

The module’s compact form factor and rack-mountable design ensure easy integration into existing control cabinets, saving space and simplifying installation.

Applications:

The ABB XVC768116 3BHB007211R116 DCS PLC Module is suitable for a wide range of applications, including:

- Power Generation: Used in power plants for the control of turbines, generators, and energy distribution systems.

- Oil & Gas: Applied in refining, pipeline control, offshore platforms, and wellhead control systems.

- Chemical Processing: For controlling reactors, batch processes, and monitoring chemical production.

- Water Treatment: Used for monitoring and controlling filtration, chemical dosing, and distribution in water treatment plants.

- Manufacturing: Ideal for automation of industrial processes and control of factory operations requiring real-time decision-making and flexible I/O configurations.

Conclusion:

The ABB XVC768116 3BHB007211R116 DCS PLC Module is an advanced, high-performance DCS PLC module designed for complex industrial automation systems. With real-time data processing, flexible I/O configuration, redundancy features, and advanced diagnostic capabilities, this module is built to ensure continuous, reliable performance in demanding industrial environments. Ideal for mission-critical applications across industries such as power generation, oil & gas, chemical processing, and manufacturing, it provides a scalable and robust solution for automation and control systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922