الوصف

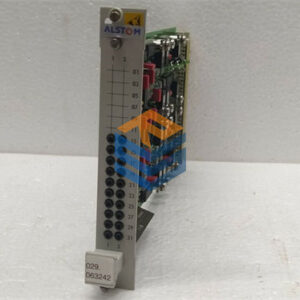

Ah, my friend! When you specify ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0, you’re looking at a dedicated Output Module from Alstom, likely designed for controlling field devices, and the “VOOB8” strongly indicates it’s a Valve Output Module with 8 channels.

This module is a crucial component within Alstom’s industrial control systems, particularly in environments where precise control over actuators like valves is essential. Given Alstom’s legacy in power generation, grid solutions, and especially rail transport, this module would be found in systems where reliable output signals are needed to manage complex machinery or processes.

Enhanced Search Titles:

- ALSTOM VOOB8-B 12004-106-04 V1.0.0: 8-Channel Valve Output Module

- ALSTOM VOOB8-B: Digital Output Control for Industrial Applications

- Valve Output Module 12004-106-04: Essential for Alstom Control Systems

- ALSTOM I/O Modules: Understanding the VOOB8-B’s Role in Automation

- VOOB8-B V1.0.0: Precision Control in Power Plant & Rail Systems (Alstom)

- ALSTOM 12004-106-04: Managing Actuators in Critical Infrastructure

- 8-Channel Output Card VOOB8-B: Alstom’s Solution for Field Device Control

- ALSTOM VOOB8-B: Ensuring Reliable Command Execution in Automated Processes

- Legacy Alstom Control: Focus on the VOOB8-B Digital Output Module

- 12004-106-04: The Actuator Interface in Alstom’s DCS and PLC Systems.

Brief Product Overview:

The ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0 is an electronic output module, likely providing 8 channels of digital or specialized valve outputs. Manufactured by Alstom, it serves as the interface between the central control system (such as a Distributed Control System (DCS) or Programmable Logic Controller (PLC) from the ALSPA P320 family) and field actuators. Its primary function is to receive digital commands from the controller and convert them into electrical signals capable of operating devices like solenoid valves, motor contactors, indicator lights, or other binary output devices in industrial settings.

- Type: Output Module (likely for valves or digital signals)

- Channels: 8 outputs

- Primary Function: Converts digital control commands into electrical signals for field actuators.

- Operating Environment: Designed for robust industrial environments, capable of withstanding typical industrial conditions.

- Applications: Power generation (e.g., valve control in turbine or boiler systems), industrial process control, and potentially railway applications (e.g., signaling or auxiliary system control).

Detailed Product Description:

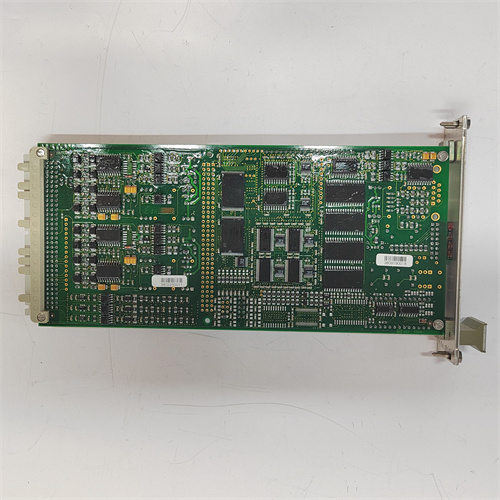

My friend, in the intricate world of industrial automation, the ability to precisely control physical equipment is paramount. While input modules gather data, output modules, like the ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0, are the workhorses that translate the “brain’s” (controller’s) decisions into physical actions. This module is the crucial link that enables a control system to actively manage the operational state of a plant, process, or vehicle.

Given the “VOOB8” designation, this module is highly specialized for valve output control, likely providing 8 independent channels. This suggests it can command up to eight different valves or other similar binary actuators (e.g., solenoids, contactors).

Its Core Function in Control Systems:

The VOOB8-B would operate by:

- Receiving Digital Commands: It receives logic-level commands (e.g., 0 or 1, representing ON or OFF) from the central processing unit (CPU) of the DCS or PLC.

- Power Amplification: These low-power digital signals are then amplified by the module’s internal circuitry to provide sufficient voltage and current to operate industrial field devices. For valves, this might involve directly energizing a solenoid coil.

- Output Channels: With 8 channels, it can independently control eight separate devices. This is common for managing multiple valves in a process, controlling different lights on a mimic panel, or engaging various contactors.

- Isolation and Protection: Crucially, output modules like the VOOB8-B provide electrical isolation between the sensitive control electronics and the potentially noisy or high-power field devices. This protects the control system from faults or surges originating in the field. It also typically includes short-circuit protection and overload detection for each channel.

- Diagnostic Capabilities: Often, such modules include LED indicators for each channel, showing its active status, and potentially diagnostic flags that can be read by the controller to indicate issues like open circuits or short circuits in the wiring to the field device.

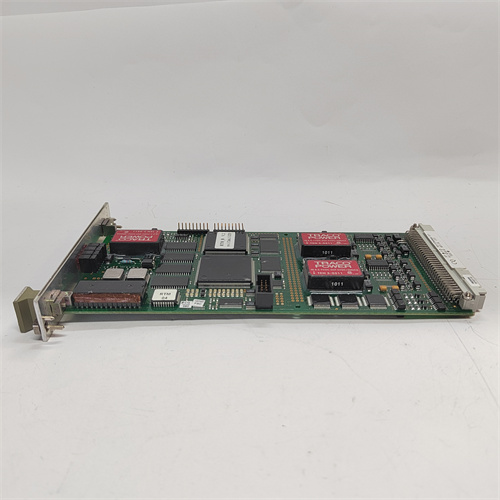

Built for Industrial Reliability:

Alstom’s legacy in demanding sectors like power generation and rail transport means that components like the VOOB8-B are built to rigorous standards. They are designed to withstand:

- Harsh Environmental Conditions: Including wide temperature fluctuations, humidity, dust, and potentially corrosive atmospheres.

- Vibration and Shock: Especially critical in railway applications.

- Electromagnetic Interference (EMI): Robust design to minimize susceptibility to and emission of electrical noise, ensuring reliable operation in electrically dense environments.

This focus on reliability ensures that the module can consistently deliver critical control commands, contributing to the safety and efficiency of the overall system.

Technical Specifications:

While exact specifications for this specific legacy part can be proprietary, we can infer general characteristics based on its type:

Typical Applications:

You would find the ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0 in various industrial automation contexts:

- Power Generation Plants:

- Controlling valves (e.g., steam valves, water valves, fuel valves) in boiler systems, turbine control systems, or balance-of-plant auxiliary systems.

- Operating motor contactors for pumps, fans, and conveyors.

- Activating alarm annunciators or indicator lights.

- Industrial Process Control: In manufacturing facilities (e.g., chemical plants, food processing, pulp and paper), controlling actuators in production lines, batch processes, or utility systems.

- Railway Systems:

- Operating point (switch) machines or signaling lamps.

- Controlling auxiliary systems on trains (e.g., door mechanisms, lighting, HVAC relays).

- Activating trackside equipment.

- Water and Wastewater Treatment Plants: Controlling pumps, valves, and chemical dosing systems.

Related Products:

As a fundamental I/O module, the ALSTOM VOOB8-B works within a larger control architecture. Related products would include:

- ALSPA P320 DCS/PLC System: This is the most likely control platform this module would belong to. It would plug into a backplane or rack within the ALSPA P320 system.

- Central Processing Units (CPUs): The main processor units within the ALSPA P320 system (e.g., ALSPA P320 CPUs) that issue commands to the VOOB8-B.

- Input Modules (e.g., ALSTOM I/OBE2): Companion modules that collect sensor data from the field.

- Communication Modules (e.g., ALSTOM I/OBUS2): Modules that manage data flow between the CPU and I/O modules.

- Power Supply Units (PSUs): To provide the necessary power for the module’s operation and for driving field devices.

- Field Actuators: The devices controlled by the VOOB8-B, such as solenoid valves, motor starters, pneumatic actuators, and indicator lights.

- Terminal Blocks and Wiring: Essential for connecting the module to the field devices.

- Modern Digital Output Modules: Contemporary equivalents from current manufacturers like Siemens (SIMATIC S7 series), Rockwell Automation (Allen-Bradley ControlLogix/CompactLogix), ABB (System 800xA), and Schneider Electric (Modicon), which offer similar functionalities with enhanced features and communication capabilities.

In summary, the ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0 is a vital output interface, enabling the control system to precisely manipulate industrial equipment and maintain operational integrity.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922