الوصف

Product Name:

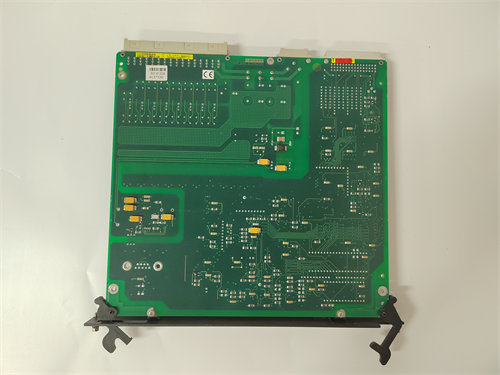

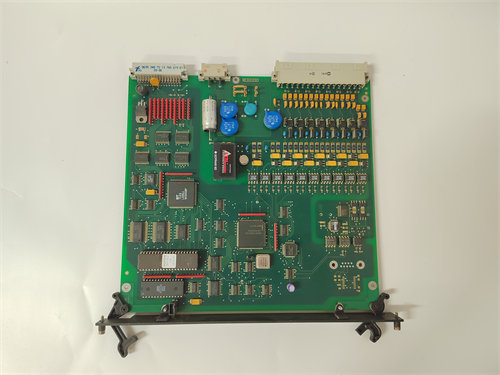

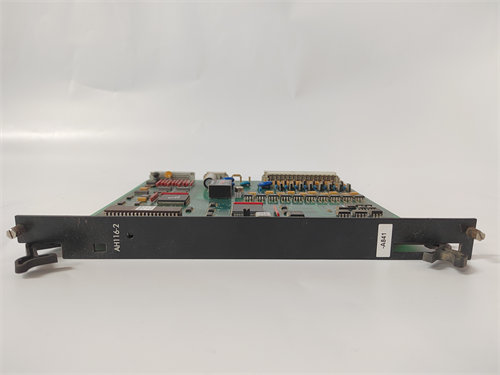

ALSTOM AH116-2 DCS PLC Module

Product Description:

The ALSTOM AH116-2 is a Distributed Control System (DCS) module designed to offer high-performance control, automation, and monitoring capabilities in industrial and energy applications. It is engineered to integrate seamlessly with ALSTOM’s process control systems, ensuring precise and reliable management of complex industrial processes. This module is particularly well-suited for power generation, oil and gas, chemical production, and water treatment industries.

The AH116-2 module serves as a crucial component in ALSTOM’s comprehensive automation solutions, providing robust and scalable control functionality. It supports a variety of industrial communication protocols and features real-time processing, data acquisition, and system diagnostics. The module is designed for high availability with redundant communication and power systems, ensuring minimal downtime in critical environments.

With its extensive configuration options and adaptability to various system architectures, the AH116-2 is perfect for controlling large-scale processes and systems that require precision, reliability, and scalability.

Product Parameters:

- Module Type: DCS/PLC Control Module (For Process Control and Automation).

- Compatibility: Fully compatible with ALSTOM’s distributed control systems for energy, chemical, and industrial applications.

- Communication Protocols: Supports Modbus, Profibus, Ethernet/IP, Profinet, and Fieldbus for networked communication and integration with external devices.

- Power Supply: Typically operates with a 24V DC input power, with options for redundant power systems to ensure reliability in critical operations.

- I/O Capacity: Offers flexible I/O configurations with both digital and analog I/O options, allowing customization based on the needs of the controlled system.

- Environment Rating: Designed for industrial environments, it can handle demanding conditions, such as high temperatures, vibration, and humidity.

- Redundancy Support: The AH116-2 provides redundant communication, redundant power supplies, and fault tolerance to ensure operational continuity.

Product Specifications:

1. Processor and Computing Power:

-

Processor Type:

- The AH116-2 module is equipped with a high-speed processor capable of real-time data processing for complex control tasks. It is built to handle large-scale control loops, processing and managing data for multiple connected devices in parallel.

-

Performance:

- The module features high-performance real-time control with fast execution of control algorithms, making it suitable for time-critical processes in industries like energy, manufacturing, and petrochemical sectors.

2. Memory:

-

RAM:

- The AH116-2 is equipped with dynamic RAM to store temporary data required for real-time processing. The memory capacity generally ranges from 8 MB to 64 MB depending on the configuration.

-

Non-Volatile Storage:

- The module comes with non-volatile flash memory or EEPROM for storing configuration data, control logic, and critical system parameters. This ensures data persistence even during power outages or system resets.

3. I/O and Expansion:

-

I/O Channels:

- Supports a wide variety of digital and analog I/O modules for connecting various types of field devices, including sensors, actuators, and control valves. This allows for highly flexible system configurations.

- The I/O count can be expanded by adding external I/O cards, modules, or via fieldbus integration.

-

Modular Expansion:

- The AH116-2 is highly scalable, supporting easy expansion with additional I/O modules, communication interfaces, and redundancy configurations for larger systems.

4. Communication and Networking:

-

Ethernet/IP and Fieldbus Integration:

- The AH116-2 module features multiple communication ports, including Ethernet/IP, Profinet, and Modbus, enabling seamless integration with ALSTOM’s DCS and other third-party control systems or field devices.

- Profibus and Fieldbus are supported for connecting remote I/O and communication devices, offering flexibility in network architecture.

-

Redundancy:

- Provides redundant communication paths (e.g., dual Ethernet or Fieldbus) to minimize the risk of network failure, ensuring high availability for critical operations.

5. Power Requirements:

-

Operating Voltage:

- Typically operates on 24V DC (± 10%) or 48V DC power supplies depending on system configuration and environmental conditions.

-

Power Consumption:

- The typical power consumption of the AH116-2 module is approximately 25-45W, depending on the connected load and I/O usage.

6. Environmental Specifications:

-

Operating Temperature Range:

- The AH116-2 module can operate in a wide temperature range, typically between 0°C and +60°C. Some configurations may support extended ranges for more extreme conditions.

-

Humidity Range:

- Operates in environments with 5% to 95% non-condensing humidity.

-

Shock and Vibration Resistance:

- Designed to meet industrial standards for shock and vibration resistance (e.g., IEC 60068 and DIN EN 61131-2), the AH116-2 module is built to withstand the mechanical stresses often found in industrial environments.

-

Protection Rating:

- Typically rated IP20/IP65 depending on the enclosure and configuration, providing protection against dust, moisture, and other environmental factors.

7. Physical and Mechanical Specifications:

-

Form Factor:

- The AH116-2 module is typically DIN Rail mountable, allowing easy installation and integration into existing industrial control systems or control cabinets.

-

Dimensions:

- Approximate size of the module is 160 mm x 130 mm x 40 mm (HxWxD), but this can vary depending on the configuration and specific modules attached.

-

Weight:

- Around 0.8 to 1.5 kg, depending on the number of I/O cards and accessories integrated into the module.

Key Features and Benefits:

-

Real-Time Control:

- Provides real-time processing to control industrial processes with high precision, ensuring reliable and responsive operation.

-

Highly Flexible and Scalable:

- Easily integrates into large-scale control systems, with the ability to scale by adding more I/O modules or communication units.

-

Redundancy and High Availability:

- Offers built-in redundancy for communication and power supplies, ensuring high reliability and uptime in mission-critical applications.

-

Environmental Durability:

- Designed to withstand harsh industrial environments, including high temperatures, vibrations, and humidity, ensuring robust performance.

-

Seamless Integration:

- Supports multiple industrial communication protocols, making it easy to integrate with various other automation systems and devices.

Applications:

- Power Generation: Used in power plants to control turbines, boilers, and other critical equipment.

- Chemical and Petrochemical: Controls and monitors production lines and chemical processing plants.

- Water Treatment: For automating water and wastewater treatment plants, controlling filtration and dosing systems.

- Oil and Gas: Applied in refineries, oil rigs, and gas plants for reliable process control and monitoring.

- Industrial Automation: Provides control in manufacturing, assembly lines, and large industrial automation systems.

Conclusion:

The ALSTOM AH116-2 DCS PLC Module is a robust, high-performance control module designed for industrial and energy applications. Its real-time processing capabilities, flexible communication options, and redundancy features make it ideal for mission-critical systems requiring high reliability and uptime. Whether used in energy, chemical, or water treatment, the AH116-2 offers a scalable and customizable solution to meet the control needs of complex industrial environments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922