الوصف

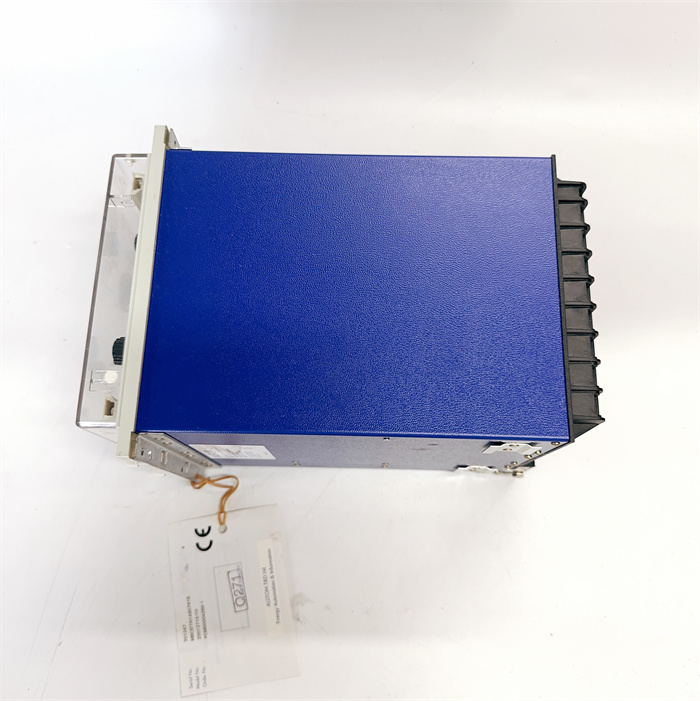

ALSTOM MBCI01N1AB0761B DCS PLC Module

Product Name:

ALSTOM MBCI01N1AB0761B DCS PLC Module

Product Description:

The ALSTOM MBCI01N1AB0761B is a Distributed Control System (DCS) module specifically designed for use in industrial automation and control systems. Manufactured by ALSTOM, a leading player in the energy and industrial sectors, this module is designed to meet the needs of industries that require high levels of precision, reliability, and flexibility in process control.

The MBCI01N1AB0761B is ideal for applications in power generation, chemical processing, oil & gas, and other industries requiring advanced process control and monitoring. It supports real-time data acquisition and control, advanced diagnostics, and communication with other field devices. Designed for harsh industrial environments, it is known for its durability, redundancy features, and ease of integration into existing systems.

The module offers flexibility in terms of I/O configuration, scalability, and communication protocols, enabling users to expand and adapt their control systems as their needs evolve. It also ensures system redundancy to maintain high availability and continuous operation, even in the event of component failure.

Product Parameters:

-

Model Number:

MBCI01N1AB0761B -

Manufacturer:

ALSTOM (a part of General Electric’s energy division, now known for its power and automation technologies) -

Type:

DCS PLC Module (Distributed Control System and Programmable Logic Controller) -

System Compatibility:

Compatible with ALSTOM’s EPC and Distributed Control System (DCS) platforms, as well as other industrial automation systems. It is designed to integrate seamlessly with control panels, I/O systems, and other field equipment. -

Power Supply:

- Nominal Voltage: 24V DC (common for industrial DCS modules)

- Power Consumption: Varies based on configuration, with an average range of 10W to 25W.

-

Operating Temperature:

- Range: -20°C to +70°C, capable of withstanding the temperature extremes found in many industrial environments.

-

Weight:

- Approx. 1.0 – 2.0 kg, depending on the configuration and I/O options.

-

Environmental Conditions:

- Humidity: Up to 95% (non-condensing)

- Vibration Resistance: Meets industrial standards for vibration and shock resistance.

Specifications:

-

I/O Channels:

- Digital Inputs (DI): Up to 32 channels, typically used for binary signal inputs such as switches or relays.

- Digital Outputs (DO): Up to 32 channels for controlling actuators, relays, or other binary devices.

- Analog Inputs (AI): 8-16 channels for continuous measurement of analog signals like pressure, temperature, or flow rate.

- Analog Outputs (AO): 8-16 channels to output control signals for actuators such as valves, motors, or other analog-controlled devices.

-

Processor:

- Real-Time Control: Designed to execute control algorithms with minimal latency, ensuring that critical operations are handled promptly and accurately.

- Control Algorithms: Supports PID (Proportional, Integral, Derivative) control, Cascade Control, Batch Control, and Advanced Process Control strategies.

-

Memory:

- The module includes a sufficient amount of onboard memory for control logic, I/O mappings, and diagnostic data storage.

-

Communication Protocols:

- Ethernet/IP: High-speed communication for real-time data transfer between the DCS module and external systems.

- Modbus RTU/TCP: For communication with remote devices and I/O modules over industrial networks.

- Profibus: A widely used fieldbus communication protocol for connecting to field devices like sensors, actuators, and controllers.

- HART: Used for smart field devices such as pressure or temperature transmitters.

-

Redundancy:

- Supports redundant configurations for both communication and power supply. This ensures the module remains operational even in the event of failures, critical for mission-critical systems in power plants or chemical processing facilities.

-

Diagnostic Capabilities:

- The module provides self-diagnostics that allow operators to monitor the health of the system and detect potential issues before they cause downtime. It supports event logging, alarm management, and real-time status indicators for quick fault detection.

-

Safety Standards:

- Depending on the configuration, the module may meet SIL 2/SIL 3 (Safety Integrity Level) standards for use in safety-critical applications, especially in industries like oil & gas, chemical, and energy generation.

-

Mounting and Form Factor:

- Rack-Mountable: The module is designed to fit into a standard rack-mounted configuration, typically part of a larger DCS system.

- Compact Design: Facilitates easy integration into existing control cabinets, saving space and simplifying installation.

Applications:

The ALSTOM MBCI01N1AB0761B DCS PLC Module is designed for a variety of industrial applications, including:

- Power Generation: Control of turbines, generators, and energy distribution systems in power plants.

- Oil & Gas: Automation and monitoring of drilling rigs, refineries, and pipeline systems.

- Chemical Processing: Control of chemical reactors, batch processes, and distillation columns.

- Water Treatment: Used for managing water filtration, chemical dosing, and distribution.

- Manufacturing: Suitable for process control in industrial manufacturing, including automated production lines and material handling.

Conclusion:

The ALSTOM MBCI01N1AB0761B DCS PLC Module is a versatile, high-performance control module ideal for use in complex industrial automation systems. With its advanced diagnostics, real-time control capabilities, redundancy, and scalability, this module is well-suited for critical applications across power, chemical, and manufacturing industries. The flexible I/O configuration and support for multiple communication protocols ensure smooth integration with a wide range of devices and systems, while its durability and safety compliance make it an ideal solution for harsh industrial environments.

Key Features:

-

Real-Time Data Acquisition and Control:

The module supports real-time data processing, allowing for immediate responses to process changes. This ensures precision in controlling industrial processes. -

Flexible I/O Configurations:

The system can be customized to meet specific process control requirements, offering flexibility in terms of digital and analog inputs/outputs. -

Advanced Diagnostics and Monitoring:

Provides robust diagnostic tools to monitor system performance, detect errors, and facilitate troubleshooting. It logs critical events and can alert operators to potential issues. -

Scalability:

The MBCI01N1AB0761B can be integrated into both small-scale and large-scale systems, offering flexibility for future expansions and changes in control requirements. -

High Redundancy:

Features redundant power supplies and communication paths to ensure that the system remains operational even in case of failure of critical components, ensuring high system availability. -

Industrial Communication Protocol Support:

The module supports several industrial communication protocols such as Modbus, Profibus, and Ethernet/IP, ensuring easy integration with a wide range of devices and systems. -

Durable Design:

Built to withstand the harsh conditions typically encountered in industrial environments, including high temperatures, humidity, and vibrations. -

Safety Integrity:

It is capable of meeting SIL 2/SIL 3 standards, making it suitable for safety-critical applications in industries like power generation, chemical plants, and oil refineries.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922