الوصف

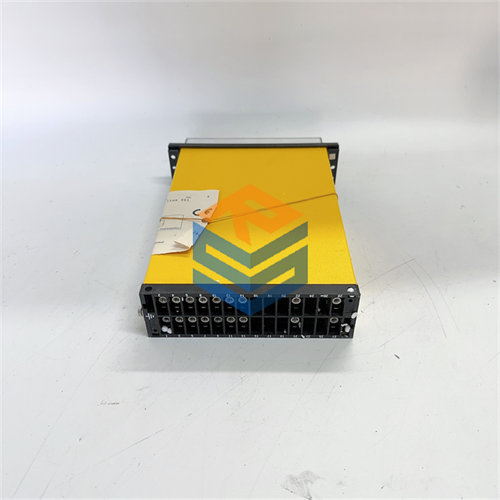

The ALSTOM MVAW11B1AB9007A DCS PLC Module is part of the industrial automation systems offered by ALSTOM, a leading global provider of energy, automation, and control solutions. The module is typically used in Distributed Control Systems (DCS) for complex automation and control applications, particularly in the power generation and process industries.

Here’s a detailed breakdown of the ALSTOM MVAW11B1AB9007A DCS PLC Module:

Product Name

- ALSTOM MVAW11B1AB9007A DCS PLC Module

Product Description

The ALSTOM MVAW11B1AB9007A is a Distributed Control System (DCS) module designed to integrate seamlessly into larger control systems for industries such as power generation, chemical processing, and oil & gas. This module plays a crucial role in managing complex processes, providing real-time control, monitoring, and data acquisition for critical industrial applications.

As part of ALSTOM’s suite of automation solutions, the MVAW11B1AB9007A module provides high-speed data processing, a variety of communication protocols, and robust diagnostics to ensure reliability in harsh operational environments. It integrates with ALSTOM’s broader DCS infrastructure, ensuring smooth communication across multiple systems and control loops.

Product Parameters & Specifications

- Model Number: MVAW11B1AB9007A

- Type: DCS PLC Module

- Application: Used in distributed control systems for industrial applications, such as power plants, chemical plants, and energy systems

- Supply Voltage: Typically 24V DC (may vary based on model and configuration)

- Communication Protocols:

- Ethernet/IP

- Modbus

- Profibus DP/PA (or other fieldbus protocols depending on system configuration)

- Profinet (may vary depending on model)

- Input/Output Channels:

- Digital Inputs: 16 to 32 channels (depending on configuration)

- Digital Outputs: 16 to 32 channels (depending on configuration)

- Analog Inputs/Outputs: Available in some configurations for controlling process variables like temperature, pressure, and flow

- Processing Speed: Real-time data processing, with input/output response time typically under 1 millisecond.

- Dimensions:

- Height: Approximately 150mm

- Width: 200mm

- Depth: 100mm (subject to slight variation depending on version)

- Weight: Approx. 2-3 kg (depends on configuration)

- Power Consumption: 5-10W (depending on the number of I/O channels and communication setup)

- Environmental Conditions:

- Operating Temperature: -20°C to 60°C (may vary depending on the exact configuration)

- Humidity Range: 5% to 95% non-condensing

- Vibration Resistance: Designed to withstand typical industrial vibration levels

- Status Indicators:

- LED Indicators: For power status, communication status, input/output status, and fault indication.

- Mounting Type: DIN Rail or Panel Mount (depending on the specific model configuration)

- Certifications:

- CE

- UL

- RoHS

- ISO and IEC standards compliance for industrial automation

- EMC Compliant

Key Features

-

Real-Time Control: The MVAW11B1AB9007A module offers real-time processing of both digital and analog signals, ensuring precise control over complex automation tasks. Its low-latency response times make it ideal for critical applications in industries like power generation and chemical processing.

-

Advanced Diagnostics and Monitoring: With built-in diagnostic functions, this module supports system health monitoring and error diagnostics, helping to reduce downtime and improve maintenance efficiency. It can automatically detect faults or deviations from normal operating conditions and alert operators.

-

High-Compatibility Communication: The MVAW11B1AB9007A supports multiple communication protocols (Ethernet/IP, Modbus, Profibus, etc.), allowing it to integrate easily into existing control systems and networks. This flexibility ensures compatibility with both new and legacy equipment.

-

Scalability: Designed to be part of a larger distributed control system, the MVAW11B1AB9007A module can scale to accommodate the needs of large, complex systems. Additional I/O modules can be added to extend its capabilities as the system grows.

-

Robust Construction: Built to handle the rigors of industrial environments, the module features protection against electrical noise, temperature fluctuations, and mechanical vibrations. It is ideal for use in industries such as power plants, oil & gas, and chemical processing.

-

Customizable Inputs and Outputs: Depending on the version and configuration, the MVAW11B1AB9007A module can offer a range of I/O options, including digital and analog inputs/outputs, which can be tailored to meet specific application requirements.

Applications and Use Cases

-

Power Generation: The module can be used to control and monitor power plant equipment, such as turbines, generators, and pumps. It is capable of handling the complex control systems required for large-scale energy production.

-

Oil & Gas: The MVAW11B1AB9007A is also used for controlling systems in oil and gas facilities, where precise automation is essential for operations like refining, distribution, and exploration.

-

Chemical Processing: In chemical plants, this module can be used to control reactors, conveyors, pumps, and other automated processes.

-

Water Treatment and Utility Management: The module can monitor and control water distribution systems, ensuring safe and efficient operations in water treatment facilities.

Comparison with Competing Products

Compared to other DCS and PLC modules from competitors such as Siemens, Honeywell, or Schneider Electric, the ALSTOM MVAW11B1AB9007A offers similar capabilities in terms of real-time control, communication flexibility, and I/O handling. However, its primary strength lies in its integration with ALSTOM’s larger DCS solutions, particularly in power generation and utility automation sectors.

- Siemens PLCs: Siemens offers similar functionality, but ALSTOM systems tend to be more specialized for energy and utility sectors, providing tighter integration with equipment like turbines and generators.

- Honeywell: Honeywell’s DCS systems are robust, but ALSTOM’s MVAW11B1AB9007A module may offer better integration with ALSTOM’s power plant solutions, providing advantages in energy-specific use cases.

- Schneider Electric: Schneider’s systems are widely used in process automation, and while they provide comparable features, ALSTOM’s modules are generally seen as offering better performance in energy-intensive applications.

Selection Tips and Considerations

-

Industrial Application: If your operations involve power generation, utility automation, or complex industrial processes, the MVAW11B1AB9007A module is an excellent choice due to its real-time control and integration capabilities within ALSTOM’s DCS ecosystem.

-

Compatibility: Ensure that the communication protocols offered by the MVAW11B1AB9007A are compatible with your existing infrastructure, especially if integrating with legacy systems or other vendors’ control systems.

-

Scalability Needs: Depending on your project’s scale, check the scalability of the module and ensure that the configuration you select can meet future expansion requirements without needing a complete system overhaul.

-

Environmental Considerations: Always review the operational environment and temperature range requirements. For extremely harsh environments, consider if extended temperature range or special enclosures are required.

For more detailed information about the ALSTOM MVAW11B1AB9007A DCS PLC Module, its configuration options, or to request a quote, you can contact ALSTOM Automation or an authorized distributor.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922