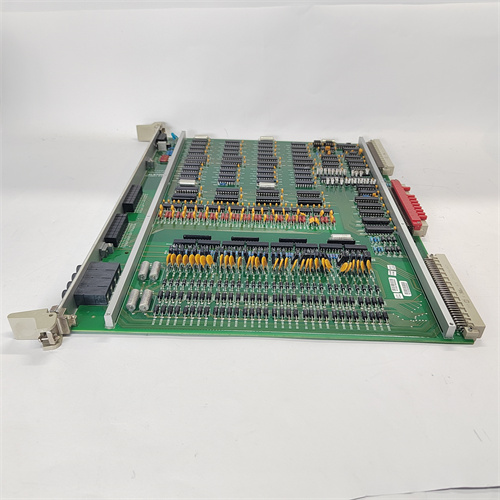

الوصف

The ALSTOM N895609510K, N895609010R, E32OUT N895609100P series likely refers to DCS (Distributed Control System) and PLC (Programmable Logic Controller) modules designed by Alstom (now part of GE Power). These modules are designed for use in industrial automation and control systems, specifically in applications where power generation, energy, transportation, chemical processing, and similar industries require reliable, scalable, and flexible automation solutions.

The exact model names you’ve provided seem to refer to specific modules used within Alstom’s control systems, potentially for power plant or industrial automation environments.

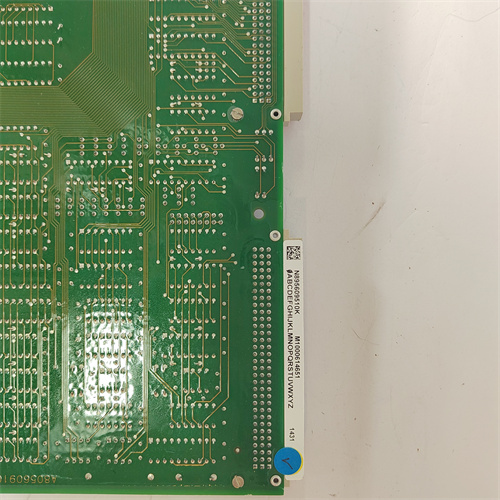

Product Name:

- ALSTOM N895609510K DCS PLC Module

- ALSTOM N895609010R DCS PLC Module

- ALSTOM E32OUT N895609100P DCS Output Module

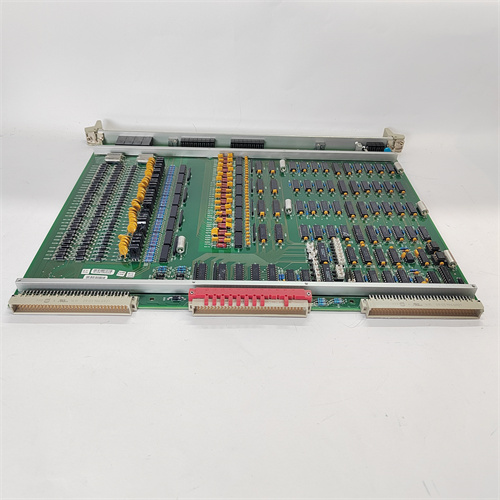

Product Description:

These modules are part of Alstom’s DCS/PLC solutions, which are used in various industrial automation systems, particularly in power generation, water treatment, chemical, and transportation industries. They allow real-time control, monitoring, and data processing for industrial processes. These modules are critical for controlling and automating machinery, processes, and other operational components across complex systems.

ALSTOM DCS modules are typically designed for continuous control systems in industrial environments, while the PLC modules are optimized for discrete control tasks. The E32OUT N895609100P seems to be an output module that interfaces with field devices, possibly dealing with actuators or signal processing.

Key Features:

- Real-time Process Control: These modules provide fast processing for control of industrial systems.

- Modular and Scalable Design: Easy to scale by adding additional modules to suit changing industrial requirements.

- High Availability and Reliability: Designed for 24/7 operations in harsh industrial environments.

- Flexible I/O: Handles both digital and analog inputs/outputs for a wide range of industrial sensors and actuators.

- Communication Compatibility: Supports various industrial communication protocols, allowing for integration with SCADA systems, other PLCs, or DCS systems.

Product Parameters & Specifications:

1. General Specifications:

- System Type: Hybrid DCS/PLC modules used in automated control and monitoring systems.

- Manufacturer: Alstom (GE Power), a leading supplier of power generation and industrial automation equipment.

- Application Areas: Primarily used in energy production, power plants, industrial process control, and chemical plants.

- Modular Design: The system allows for easy integration of various I/O and communication modules.

- Form Factor: Typically rack-mounted or panel-mounted for easy integration into industrial control panels.

2. Electrical Specifications:

- Operating Voltage: Common voltage ranges are 24V DC for logic and control circuitry, with some modules supporting higher voltages.

- Power Consumption: Typical consumption ranges between 20W to 50W per module depending on configuration.

- Signal I/O:

- Digital Inputs: Designed for field devices such as switches, sensors, or level indicators.

- Analog Inputs: Usually supports signals like 4-20mA or 0-10V, common in temperature, pressure, and flow measurements.

- Digital Outputs: Includes relays or solid-state outputs for controlling actuators, motors, valves, etc.

- Analog Outputs: Can output 4-20mA signals for controlling devices or external systems.

3. I/O Specifications:

- Digital I/O: The I/O count typically ranges from 8 to 64 digital inputs or outputs, depending on the specific module.

- Analog I/O: Typically supports 4 to 16 analog channels (input or output).

- Communication Ports:

- Supports industry-standard protocols such as Modbus TCP/IP, Profibus, Ethernet/IP, and HART for communication between modules and control systems.

- Ethernet support for connection to higher-level supervisory systems (SCADA, DCS).

4. Performance Specifications:

- Processing Power: Alstom DCS and PLC modules are designed for high-speed processing with scan times typically in the range of 2ms to 50ms.

- Response Time: Fast response times for controlling industrial systems. The scan times and response times vary based on the application and module configurations.

- Control Capacity: Designed to handle complex industrial processes and real-time control loops.

5. Environmental Specifications:

- Operating Temperature: Generally between 0°C and 60°C (32°F to 140°F) for typical industrial environments.

- Storage Temperature: Ranges from -40°C to 85°C (-40°F to 185°F).

- Humidity: Can operate in environments with 0 to 95% non-condensing humidity.

- Vibration and Shock Resistance: Modules are typically designed to meet industrial standards for vibration and shock resistance.

6. Safety & Protection:

- Overvoltage Protection: Built-in surge and overvoltage protection.

- Fault Detection: Modules include self-diagnostics to identify faults, reducing downtime.

- Isolation: Many modules are isolated to protect from electrical noise or ground loops in harsh industrial environments.

- Short-Circuit Protection: Ensures that devices connected to outputs are protected from short circuits.

7. Application Examples:

- Power Plants: Control and monitoring of turbines, generators, and auxiliary systems.

- Water Treatment: Managing water flow, filtration, and chemical dosing systems.

- Manufacturing: Used for the automation of assembly lines, motor control, and process sequences.

- Oil & Gas: Control of pumps, compressors, and remote monitoring systems.

- Chemical Processing: Managing chemical reactors, temperature control, and product flow.

Conclusion:

The ALSTOM N895609510K, N895609010R, and E32OUT N895609100P modules are crucial components of Alstom’s DCS/PLC systems, providing flexible, reliable control and automation for complex industrial processes. They support both continuous process control (DCS) and discrete control (PLC), making them suitable for a wide range of industries such as power generation, chemical processing, and manufacturing.

For specific technical documentation such as wiring diagrams, installation guides, and software compatibility, it’s recommended to contact GE Power or refer to official product manuals for Alstom DCS/PLC systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922