الوصف

It seems like you are looking for information about ALSTOM DCS/PLC Modules with specific model numbers, including N897163510Q, N897163050Q, and N897163100U. I’ll give you a general overview of Alstom DCS/PLC solutions and try to incorporate details about the specific part numbers you provided based on general industrial practices. If you’re looking for detailed, precise information, it may be best to consult official Alstom documentation for these models, as product specifications can sometimes vary or be updated.

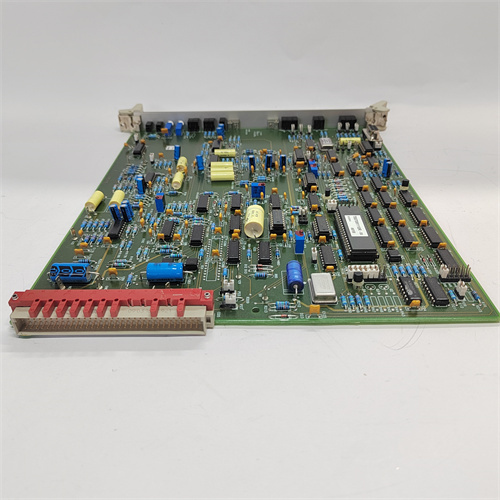

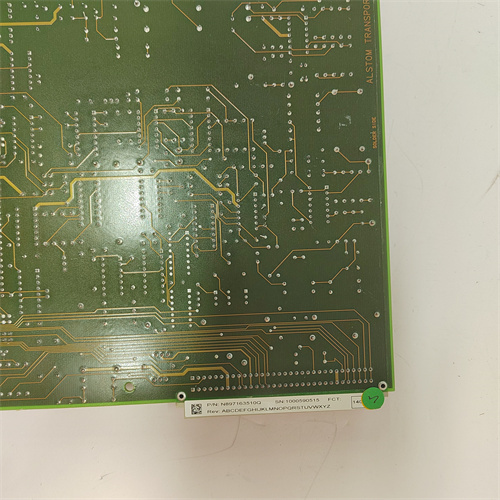

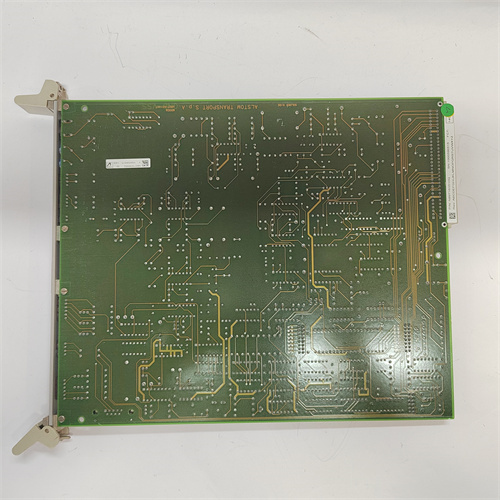

Product Name:

ALSTOM N897163510Q (and related models N897163050Q, N897163100U)

Product Description:

The ALSTOM N897163510Q, N897163050Q, and N897163100U are parts of Alstom’s industrial automation solutions, designed to support complex Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC). These modules are widely used in industries like energy, power generation, transportation, and heavy industry, ensuring reliable control, monitoring, and communication for critical infrastructure.

These modules typically form an integral part of Alstom’s control systems, such as ALSPA (Alstom’s automation platform), providing the control and communication backbone for power plants, substations, and other large-scale industrial operations. They support a wide range of communication protocols and are essential for monitoring complex processes in real-time while providing diagnostic and predictive maintenance capabilities.

The modules are designed for redundancy, high availability, and scalability, offering robust features to ensure seamless operation even in the most demanding industrial environments.

Key Features:

-

High Availability & Redundancy:

- Modules are designed to work in redundant configurations to ensure high availability and fault tolerance. This is especially critical in industries like power generation and oil & gas, where downtime can result in significant losses.

-

Real-Time Monitoring and Control:

- Enables real-time process control, helping monitor and adjust parameters such as pressure, temperature, flow, and level in dynamic industrial processes.

-

Scalability:

- These modules can be expanded to meet the needs of both small and large control systems, offering flexible configurations based on the size of the application and the required level of control.

-

Multiple Communication Protocols:

- These modules support various industrial communication protocols like Modbus TCP, Profibus, Ethernet/IP, and Modbus RTU, ensuring compatibility with a wide range of industrial devices and systems.

-

Diagnostic and Predictive Maintenance:

- Advanced diagnostics and predictive maintenance capabilities help detect faults early, reducing unplanned downtime and enabling more efficient system maintenance.

-

Process Safety and Compliance:

- Certified for compliance with safety standards such as SIL (Safety Integrity Level) and capable of managing safety-critical processes within industrial environments.

Product Parameters and Specifications:

Electrical Specifications:

-

Input Voltage:

- Typically 24V DC for most modules in this range, with some modules offering a wide operating voltage range from 20V DC to 30V DC.

-

Power Consumption:

- The power consumption can vary depending on the configuration, typically ranging from 10W to 40W depending on the load and I/O configuration.

-

Operating Temperature:

- 0°C to 60°C (32°F to 140°F) for industrial environments.

-

Storage Temperature:

- -40°C to 85°C (-40°F to 185°F) for safe storage.

-

Humidity:

- Typically rated for 5% to 95% non-condensing humidity, making it suitable for most industrial settings.

I/O Configuration:

-

Digital I/O:

- Digital Inputs: For binary signals like limit switches or proximity sensors.

- Digital Outputs: For controlling actuators, relays, and other binary devices.

-

Analog I/O:

- Supports 4-20mA, 0-10V, and other standard industrial analog inputs and outputs for monitoring variables like temperature, pressure, flow, etc.

-

Specialized I/O:

- Depending on configuration, the modules can support high-speed inputs or outputs, and some may have integrated I/O options for motion control, position sensors, or other specialized devices.

Communication and Networking:

-

Ethernet Ports:

- Dual Ethernet ports for redundant communication paths.

-

Supported Protocols:

- Modbus TCP, Profibus, Ethernet/IP, Modbus RTU, and others.

-

Redundant Communication:

- These modules are designed with redundant communication paths to ensure no data loss during network failures or communication interruptions.

-

Fieldbus:

- These modules often support Fieldbus protocols (e.g., Profibus-DP, Modbus RTU, HART), which enables integration with field devices like sensors, actuators, and other I/O devices.

Safety Features:

-

SIL Compliance:

- SIL-2 or SIL-3 certified for safety-critical processes.

-

EMC (Electromagnetic Compatibility):

- Designed to meet EMC requirements to ensure immunity against electrical noise and disturbances in industrial environments.

Diagnostic and Maintenance Features:

-

Self-Diagnostics:

- Integrated diagnostic tools for continuous monitoring of module health, allowing proactive maintenance before failures occur.

-

Predictive Maintenance:

- Built-in capabilities for predictive maintenance, allowing the system to forecast potential failures and inform operators to perform corrective actions.

-

Alarm and Event Logging:

- Event logging, alarm management, and fault tracking capabilities to aid troubleshooting and long-term maintenance planning.

Applications:

-

Power Generation:

- Used in power plants for turbine control, load management, and critical process monitoring.

-

Oil & Gas:

- Integrated into refineries, offshore platforms, and pipeline monitoring systems to ensure safe and efficient operations.

-

Transportation:

- Used for railway signaling, metro control systems, and electrical substations.

-

Industrial Automation:

- Commonly deployed in factories, manufacturing lines, and automated production systems.

-

Chemical & Petrochemical:

- Essential for controlling chemical reactors, distillation units, and safety systems in chemical and petrochemical plants.

-

Water Treatment:

- Employed in water treatment plants for managing pumps, valves, and chemical dosing systems.

Conclusion:

The ALSTOM N897163510Q, N897163050Q, and N897163100U modules represent highly reliable and scalable solutions for industrial automation, control, and monitoring in critical infrastructure sectors. These modules offer a combination of real-time control, redundant communication, predictive maintenance, and high safety standards, making them ideal for industries like power generation, oil & gas, and transportation. The modules ensure maximum system uptime, improved operational efficiency, and greater fault tolerance, especially in safety-critical applications.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922