الوصف

The ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module is part of Alstom’s Distributed Control System (DCS) product line, commonly used in industries such as power generation, oil & gas, chemical processing, and more. Below are the detailed product specifications, description, and parameters for the ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module:

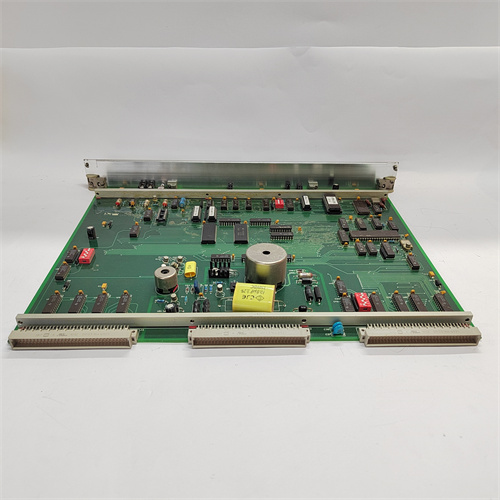

ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module

Product Name:

ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module

Product Description:

The ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module is a programmable logic controller (PLC) used in Alstom’s VPS (Variable Power Supply) DCS system. It is designed for process automation and control systems in high-performance, high-reliability environments. Typically found in industries like power generation, oil & gas, chemical plants, and metallurgy, this module provides efficient control and automation capabilities, offering a flexible and scalable solution for industrial applications.

The VPS 12004-102-03 V1.0.0 PLC module allows integration of field devices with process control systems. It facilitates real-time monitoring, control, and diagnostic functions, while ensuring that complex industrial processes run optimally with minimum downtime and maximum reliability. It is designed to operate in harsh industrial environments with high temperatures, vibration, and electromagnetic interference.

The module is an essential part of Alstom’s DCS system, which provides a seamless interface between the control room and field equipment, ensuring system stability, fault tolerance, and redundancy.

Product Parameters and Specifications:

- Model: VPS 12004-102-03 V1.0.0

- Type: DCS PLC Interface Module for the VPS system.

- System Compatibility: Designed for integration with Alstom VPS DCS systems.

- Primary Function: To interface field signals (analog and digital) with the control system, enabling the control of industrial equipment such as pumps, valves, motors, and other automation devices.

- Inputs/Outputs:

- Digital Inputs/Outputs: Provides discrete control signals to and from field devices.

- Analog Inputs/Outputs: Interfaces with analog sensors or actuators (such as temperature, pressure, and flow sensors).

- Communication Protocols:

- Modbus (RTU/TCP)

- Ethernet (for network communication)

- Proprietary Alstom Protocols (specific to VPS systems)

- Power Supply: Typically operates with 24 VDC or system-specific voltages.

- Operating Temperature Range:

- 0°C to 60°C (suitable for industrial environments).

- Mounting Type: Designed to be mounted in a 19-inch rack for integration within the Alstom VPS DCS system.

- Redundancy: Redundant power supply and communication paths for high availability and failover capabilities.

- Diagnostic Capabilities: Includes self-diagnostic functions for system health monitoring, real-time status indicators, and failure detection.

- Firmware/Software Compatibility: Compatible with Alstom VPS software suite, used for system programming, monitoring, and control.

- Size/Dimensions: Typically rack-mounted; specific dimensions depend on system configuration.

- Environmental Compliance: Meets industrial standards for environmental tolerance, including resistance to dust, humidity, and electromagnetic interference.

Key Features and Advantages:

- Real-Time Control: The module ensures real-time data acquisition and processing for industrial automation and control, enabling immediate response to changes in process conditions.

- Communication Flexibility: It supports multiple communication protocols, including Modbus, Ethernet, and proprietary protocols, for easy integration into heterogeneous environments.

- Redundancy: Built-in redundancy for power and communication ensures minimal downtime and high reliability in mission-critical processes.

- Self-Diagnostics: The module includes diagnostic tools to track system health, detect faults, and alert operators, facilitating faster maintenance and reduced downtime.

- Modular and Scalable: As part of the VPS DCS system, the module is part of a scalable and flexible architecture, allowing easy expansion and adaptation to growing system needs.

- Durability: Designed to operate in harsh industrial environments, ensuring continuous operation even under extreme conditions.

- High Integration: Works seamlessly with Alstom VPS control systems, providing a unified solution for automation, monitoring, and control.

Application Areas:

The ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module is used in industries that require reliable, high-performance automation and control systems, including:

- Power Generation: For controlling turbines, generators, boilers, and other power-related equipment.

- Oil & Gas: In upstream and downstream processes such as refining, chemical processing, and pumping stations.

- Chemical Processing: Used for controlling reactors, mixing processes, and distillation columns in chemical plants.

- Metallurgy: For automated control of furnace operations, rolling mills, and other metallurgical processes.

- Water Treatment: For controlling filtration, pumping stations, and chemical dosing in water treatment plants.

- Pharmaceuticals: Ensuring precise control in drug production and packaging processes.

- Food & Beverage: In breweries, dairies, and packaging plants to automate production lines.

Comparison with Competitors:

Compared to other DCS PLC modules, such as those from Siemens (S7 series) or Honeywell Experion, the ALSTOM VPS 12004-102-03 V1.0.0 PLC module stands out for:

- Tailored for Alstom Systems: The module is optimized for use within Alstom VPS DCS systems, ensuring seamless integration with other Alstom automation products.

- Redundancy Features: The built-in redundancy in power and communication provides higher reliability compared to many competitors, ensuring the system remains operational even during faults.

- Scalability: The modular design makes it easy to expand as system requirements grow, making it ideal for complex, evolving industrial processes.

- Durability: Designed for harsh industrial environments, it outperforms many alternatives in terms of tolerance to extreme conditions.

Selection Considerations:

When selecting the ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module, consider:

- System Compatibility: Ensure the module is compatible with your existing Alstom VPS DCS setup.

- Redundancy and Fault Tolerance: For critical processes, ensure that redundancy options (both power and communication) are configured.

- I/O Requirements: Confirm that the module can handle the number and type of inputs/outputs needed for your application.

- Environmental Conditions: Verify the module can withstand the environmental conditions of your specific application, such as temperature ranges and potential exposure to contaminants.

- Maintenance Support: Check the availability of Alstom support services and spare parts for long-term operational efficiency.

Conclusion:

The ALSTOM VPS 12004-102-03 V1.0.0 DCS PLC Module is a high-performance, flexible solution for distributed process control in industries requiring precision, reliability, and fault tolerance. With its redundancy, communication flexibility, and real-time processing capabilities, it is well-suited for mission-critical applications, offering high integration with Alstom VPS DCS systems to ensure optimal automation and control across a range of industries.

EMERSON 5X00301G01 / 5X00327G01 (

EMERSON 5X00301G01 / 5X00327G01 (

EMERSON 5X00497G01 PLC

5X00300G01 / 5X00321G01 EMERSON

5X00501G01 EMERSON

5X00502G01 EMERSON

EMERSON 1X00707H01

EMERSON 3A41491H96

EMERSON 5X00525G03

EMERSON 5X00529G02 PLC

EMERSON 5X00241G01 PLC

EMERSON 5X00589G01

EMERSON 5X00489G01 1P00159G01)

EMERSON 3A99158G01 OVATION I/O

EMERSON 1C31194G01 / 1C31197G01 Valve Positioner-

EMERSON 1C31194G03/ 1C31197G05 VP PLC

ICS TRIPLEX T8110B

TRICONEX 3009

TRICONEX 4351B 20

1404170-175 HONEYWELL

TDI 142511/51198651-100 SPS5785

PACIFIC SCE903AN-002-01 50

AB 1394-SJT05-C-RL/B PLC

EMERSON 1C31189G01 / 1C31192G01 s PLC

1C31166G01 / 1C31169G02 Serial LC Module ( RS-485) with PLC

Modbus_RTU protocol(Modbus_RTU) EMERSON

EMERSON 1C31233G04 / 1C31238H01 PLC

1C31166G02 / 1C31169G02 LC EMERSON

5X00119G01 / 5X00121G01 RTD 8 EMERSON

EMERSON 3A99266G01 ROP dcs

EMERSON 1C31203G01 / 1C31204G01 Remote node controllerI/O

1C31223G01 / 1C31219G01 Relay outputs (16 points/panel, 250 VAC @ 5A) Form C

EMERSON 1C31222G01 / 1C31219G01 Relay outputs (12 points/panel, 150 VDC @ 10A) Form X

EMERSON 5X00589G01 OCR1100 PLC

5X00247G05=5X00481G01+5X00226G03+5X00225G01 EMERSON

EMERSON 1C31179G01 / 1C31181G01 MAU-I/O2

EMERSON 1C31179G02 / 1C31181G02 MAU-I/O4

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922