الوصف

Ah, BENTLY 3500/94! This immediately signals that we’re talking about a crucial component within a Bently Nevada 3500 Series Machinery Protection System. Bently Nevada, now a Baker Hughes business, is the global leader in condition monitoring and machinery protection.

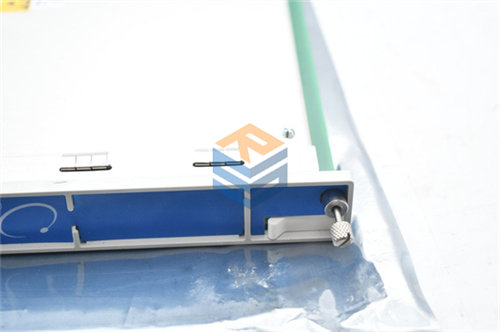

Specifically, the 3500/94 is the VGA Display Module (or often referred to as a “Display Router Box” when it’s part of a multi-rack display setup). This module is essentially the visual interface for the highly critical data collected by the 3500 system.

It’s not just a simple screen; it’s designed to present real-time and historical data from the protection system, including:

- Vibration levels

- Proximity probe gaps

- Machine speed

- Alarm event lists

- System event lists

- Module and channel data

- Custom display options configured by the user

The 3500/94 allows operators and maintenance personnel to quickly assess the health of critical rotating machinery (like turbines, compressors, pumps, and generators) without needing to connect to a separate computer for basic monitoring. It’s often paired with a separate industrial-grade VGA touch screen monitor.

SEO-Optimized Headings:

- BENTLY 3500/94: Bently Nevada VGA Display Module for Machinery Protection.

- BENTLY 3500/94: Real-Time Condition Monitoring Interface for 3500 Systems.

- Bently Nevada 3500/94: Visualize Machine Health Data with Precision.

- 3500/94 VGA Display Module: Critical Data at Your Fingertips for Plant Operators.

- BENTLY 3500/94: Enhancing Machine Diagnostics with On-Site Visualization.

- Bently Nevada 3500/94: API-670 Compliant Machinery Protection Display.

- 3500/94 Display Router Box: Consolidate Multi-Rack Bently Nevada 3500 System Data.

- BENTLY 3500/94: Reliable Monitoring for Turbines, Compressors & Rotating Equipment.

- Bently Nevada 3500/94: Intuitive Touch Screen Interface for Industrial Applications.

- 3500/94 Module: Key Component for Comprehensive Machinery Asset Management.

Brief Product Description (for detail pages and search snippet):

The Bently Nevada 3500/94 is a VGA Display Module, an integral part of the Bently Nevada 3500 Series Machinery Protection System. It provides a real-time visual interface for critical machine data, including vibration levels, alarm events, and system status, on a connected VGA touch screen monitor. Designed for demanding industrial environments, it enables operators and maintenance personnel to monitor rotating machinery health directly from the control room or machine side.

Product Type: VGA Display Module / Display Router Box Manufacturer: Bently Nevada (a Baker Hughes business) Application: Machinery Protection and Condition Monitoring Systems (Bently Nevada 3500 Series) Core Function: Visual display and interface for machine health and system status data.

Detailed Product Description:

In the world of heavy industry – power generation, oil and gas, petrochemical, and manufacturing – the smooth and reliable operation of rotating machinery is paramount. A sudden failure of a turbine, compressor, or large pump can lead to catastrophic damage, costly downtime, and even safety hazards. This is where systems like the Bently Nevada 3500 come into play, constantly monitoring these critical assets. And the Bently Nevada 3500/94 is often the “window” into that vital data. Frankly, it’s not just a screen; it’s the immediate, on-site dashboard that gives operators and technicians instant insights into machine behavior, allowing for quick decisions to prevent a trip or diagnose an issue before it escalates.

As an expert in machinery protection systems, I can tell you the Bently Nevada 3500/94 (often referred to as the 3500/94M VGA Display Module) is a core component that sits within the 3500 monitoring rack. Its primary function is to take all the real-time data being collected by the various 3500 monitor modules (e.g., vibration, thrust, speed, temperature) and present it in a user-friendly, graphical format on a standard VGA color monitor, often with touch-screen capabilities. This allows personnel to see:

- Current vibration amplitudes and phases: Crucial for identifying unbalance, misalignment, or bearing issues.

- Proximity probe gaps: Indicating shaft position, eccentricity, or proper setup.

- Machine speed: Essential for understanding operating conditions and potential overspeed situations.

- Alarm statuses: Immediately highlighting when any parameter exceeds set limits.

- System and alarm event lists: Providing a chronological record of changes and events within the monitoring system.

- Customizable displays: Operators can create bespoke screens to focus on specific machines, measurement points, or types of data relevant to their immediate needs. This includes bar graphs, numerical readouts, and API-670 compliant rack views.

Furthermore, the 3500/94 can function as a Display Router Box, allowing a single VGA display to be connected to and display data from up to four separate 3500 monitoring racks. While only one rack’s data can be viewed at a time, the alarm status of all connected racks remains visible, offering a consolidated view for larger installations and potentially reducing the number of displays required. This module is built for the rugged industrial environment, capable of operating reliably in control rooms or even closer to the machinery (when paired with appropriate industrial displays).

From a plant manager’s or reliability engineer’s perspective, the Bently Nevada 3500/94 significantly enhances operational awareness and accelerates troubleshooting. Being able to visualize critical machine data instantly, without relying solely on a separate workstation or data historian, means faster response times to developing issues, reduced diagnostic time, and ultimately, greater uptime and safety for critical assets. It provides a direct, intuitive interface to a world-leading machinery protection system.

Key Features and Core Benefits:

- Comprehensive Data Display: Presents a wide range of machinery protection data, including vibration, speed, position, and temperature measurements, along with system and alarm event lists.

- Real-time Visualization: Offers immediate, up-to-date information on machine health, enabling rapid assessment of operating conditions.

- Customizable Screens: Allows users to create and save up to nine custom display configurations, tailoring the view to specific machines, parameters, or operational needs.

- Touch Screen Interface: Supports touch screen technology on compatible VGA monitors for intuitive navigation and data access, simplifying operator interaction.

- Multi-Rack Connectivity (with Router Box): The 3500/94 can interface with a Display Router Box to enable a single VGA monitor to display data from up to four different 3500 monitoring racks, streamlining control room setups.

- API-670 Compliant View: Includes a selectable API-670 compliant rack view, which provides a familiar interface for those accustomed to industry standards for machinery protection systems.

- Robust Industrial Design: Engineered to operate reliably in demanding industrial environments, including wide temperature ranges and electromagnetic interference.

- Diagnostic Indicators: Features LEDs (OK, TX/RX) on the module to indicate proper operation and communication, aiding in quick troubleshooting.

Technical Specifications:

Areas of Application:

The Bently Nevada 3500/94 is essential in any industry relying on critical rotating machinery where continuous, reliable, and on-site monitoring of machine health is paramount for safety, efficiency, and uptime. It provides the immediate visual feedback necessary for operators and maintenance staff to react effectively to changing machine conditions.

This display module is primarily used in:

- Power Generation Plants: For monitoring steam turbines, gas turbines, generators, and large pumps in coal, gas, nuclear, and hydro power facilities.

- Oil & Gas Industry: In refineries, petrochemical plants, offshore platforms, pipelines, and LNG facilities for monitoring compressors, pumps, and other rotating equipment.

- Chemical Processing: For critical pumps, mixers, and reaction vessels where reliable operation is crucial.

- Pulp & Paper Mills: Monitoring large refiners, paper machines, and power generation equipment.

- Steel & Metals Industry: For monitoring high-speed rolling mills, fans, and pumps.

- Water & Wastewater Treatment: For large pumps and blowers in critical municipal facilities.

- Any Industrial Facility with Critical Rotating Machinery: Where unexpected downtime is costly and potentially hazardous.

Related Products You Might Be Interested In:

To form a complete Bently Nevada 3500 Series Machinery Protection System around the Bently Nevada 3500/94, you’ll need various other modules and supporting equipment. Here are some related products that complement its function or offer alternative/supporting solutions from Bently Nevada and other asset monitoring providers:

- Bently Nevada 3500 Rack: The physical enclosure that houses all 3500 modules, providing power and communication backplane.

- Bently Nevada 3500/01 Rack Interface Module (RIM): The primary interface between the 3500 rack and configuration software, as well as external communication protocols.

- Bently Nevada 3500/15 Power Supply: Provides regulated power to all modules in the 3500 rack.

- Bently Nevada 3500 Monitor Modules (e.g., 3500/40, 3500/42, 3500/50, 3500/60): These are the core modules that actually collect and process data from various sensors (e.g., vibration, speed, thrust, temperature).

- Bently Nevada Proximity Probes, Accelerometers, Velocity Transducers, and Temperature Sensors: The field devices that measure the physical parameters of the machinery and feed data to the monitor modules.

- Bently Nevada System 1 Software: A comprehensive condition monitoring and diagnostic software platform that collects, stores, analyzes, and displays data from 3500 systems and other Bently Nevada devices for advanced analytics and prognostics.

- Industrial VGA Touch Screen Monitors: Compatible displays from manufacturers like Advantech that interface with the 3500/94 module.

- Bently Nevada 3500/94 Display Router Box: An optional accessory that allows one display to serve up to four 3500 racks.

- KVM Extenders: For extending the distance between the 3500/94 module and the VGA display monitor over long distances (e.g., using CAT5 or fiber optic cables).

- Other Condition Monitoring Systems (e.g., GE Measurement & Control, Rockwell Automation, Siemens): Competing or complementary solutions for machinery health monitoring, though Bently Nevada’s 3500 series is specifically for protection.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922