الوصف

Product Name:

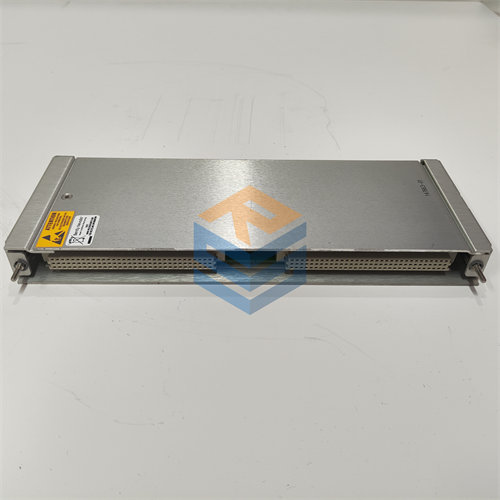

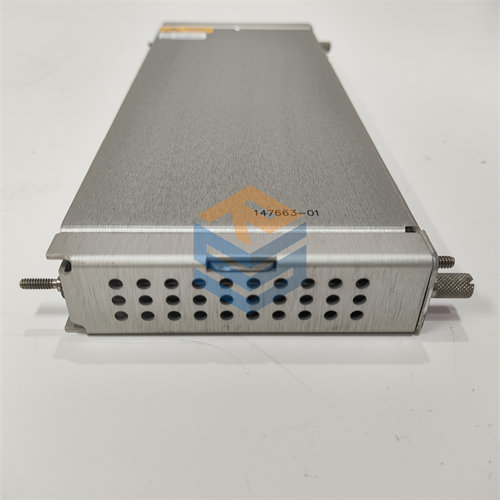

BENTLY 3500/94 147663-01 DCS PLC Module

Product Description:

The BENTLY 3500/94 147663-01 is a high-performance vibration monitoring and protection system module from Bently Nevada, a division of Emerson. It is part of the Bently 3500 Series Machinery Protection System and is designed specifically for vibration monitoring, temperature, and other key machinery parameters within industrial automation systems, particularly in rotating machinery such as turbines, compressors, generators, pumps, and motors.

This module provides critical monitoring capabilities to detect early signs of machinery malfunction, preventing damage or failure that could lead to costly repairs or unplanned downtime. The 3500/94 module can be used for vibration protection, ensuring safe operation of machinery by continuously analyzing vibration signals and other process data.

The 3500/94 147663-01 is designed to meet the rigorous demands of industrial environments, where it operates as part of a comprehensive machinery protection and condition monitoring system. It integrates seamlessly into DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and other automation systems, ensuring the effective integration of safety, monitoring, and control.

Product Parameters:

- Model: BENTLY 3500/94 147663-01

- Type: Vibration Monitoring and Protection Module

- Manufacturer: Bently Nevada (Emerson)

- Series: Bently 3500 Series Machinery Protection

- Applications: Vibration monitoring, machinery protection, condition monitoring for rotating equipment like turbines, pumps, motors, and compressors

- Compatible Systems: Works with Bently 3500 Machinery Protection System and integrates into DCS/PLC environments

- Functionality: Vibration and temperature monitoring, machinery protection, early fault detection, and diagnostics

Product Specifications:

General Features:

-

Vibration Monitoring:

- Designed to monitor vibration levels in critical machinery, helping detect misalignments, imbalance, bearing failures, and other potential issues.

- Can handle both low-frequency and high-frequency vibration measurements, making it suitable for a wide range of machinery types.

-

Protection and Safety:

- Provides real-time protection by continuously monitoring vibration signals, triggering alarms, or shutdowns if pre-defined thresholds are exceeded, preventing potential damage.

- Ensures that machinery operates within safe limits by detecting early signs of mechanical faults.

-

Temperature Monitoring:

- Supports temperature measurements for critical components such as bearings and motors. This feature is vital for detecting overheating or other temperature-related failures.

-

Machinery Condition Monitoring:

- Allows for advanced machinery condition monitoring by analyzing vibration data and other parameters, helping maintenance teams predict failures before they occur, optimizing asset management.

-

System Integration:

- Compatible with DCS and PLC systems, making it easy to integrate into existing automation infrastructure.

- Offers analog and digital I/O interfaces to communicate with the control systems.

-

Built-in Diagnostics:

- The module includes self-diagnostics capabilities, providing status updates and fault reports to the control system, ensuring that operators can quickly identify and address any issues.

-

Real-Time Data Processing:

- Delivers real-time analysis and monitoring of vibration signals, providing immediate feedback to ensure timely interventions and prevent catastrophic failures.

Electrical Specifications:

-

Power Supply:

- Nominal Input Voltage: Typically 24 V DC, suitable for industrial control applications.

- Power Consumption: Typically consumes low power, designed to be energy-efficient in continuous monitoring applications.

-

Input Types:

- Vibration Sensors: Accepts signals from vibration transducers (e.g., proximity probes, accelerometers), usually in the form of 4-20mA current signals or digital signals.

- Temperature Sensors: Accepts temperature signals from temperature sensors or thermocouples for critical machinery components.

-

Output Types:

- Relay Outputs: Provides relay outputs for alarm signals, system status, or protection shutdowns.

- Analog Outputs: Typically outputs 4-20mA or 0-10V for data transmission to control systems or monitoring equipment.

-

I/O Capability:

- Typically provides a combination of analog inputs (for vibration and temperature sensors) and relay outputs (for alarms and protection).

Mechanical Specifications:

-

Dimensions:

- The module is designed to fit standard rack-mounted configurations for easy integration into control cabinets and racks.

- Height: Approximately 3.5 inches (89 mm)

- Width: Approximately 6.5 inches (165 mm)

- Depth: Approximately 10 inches (254 mm)

-

Weight:

- Typically weighs between 1.5-2 kg, depending on the specific configuration.

-

Mounting:

- Can be mounted on 19-inch racks (industry standard), allowing for easy integration in machinery protection systems and control cabinets.

Environmental Specifications:

-

Operating Temperature:

- 0°C to 60°C (32°F to 140°F), suitable for use in most industrial environments with standard temperature conditions.

-

Storage Temperature:

- -40°C to 85°C (-40°F to 185°F), ensuring that the module remains operational even in extreme storage conditions.

-

Humidity:

- Operates in environments with up to 95% relative humidity, non-condensing, making it suitable for humid industrial environments.

-

Vibration and Shock Resistance:

- Built to handle

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922