الوصف

Enhanced SEO Titles

- Bently 3500/94M 184826-01: VGA Display Module for Machinery Protection

- Real-time Machine Monitoring with Bently Nevada 3500/94M 184826-01

- 184826-01: Bently Nevada 3500/94M VGA Interface for Industrial Displays

- Optimize Your View: Bently Nevada 3500/94M 184826-01 Display Solution

- Bently 3500/94M 184826-01: Critical Data Visualization for Turbomachinery

- Enhance Operations with Bently Nevada 3500/94M Display Capabilities

- 3500/94M 184826-01: The Visual Hub of Your Bently Nevada System

- Reliable Display Module: Bently Nevada 3500/94M 184826-01 for Harsh Environments

- Streamline Monitoring: Bently 3500/94M 184826-01 VGA Output Module

- Bently Nevada 3500/94M 184826-01: Your Window into Machine Health

Brief Product Description

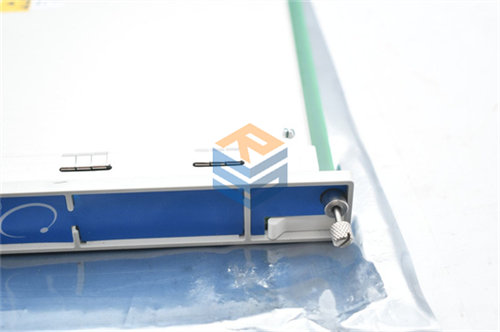

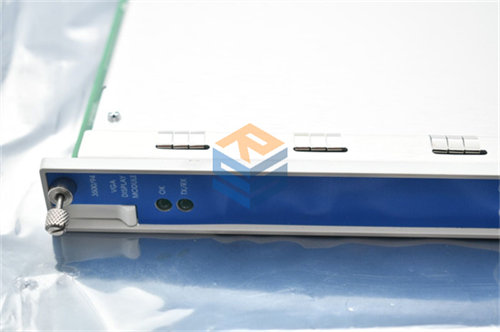

The Bently 3500/94M 184826-01 is the VGA Display Module for the Bently Nevada 3500 Series Machinery Protection System. This module acts as the interface between the 3500 rack and a standard VGA display monitor (often a touchscreen industrial monitor). It collects and processes data from all the monitoring modules within the 3500 rack and presents a real-time view of system events, alarm lists, channel data, and customizable display options to operators. This allows for immediate visualization of critical machine health information, enabling swift decision-making and enhancing operational awareness in demanding industrial environments.

- Product Type: VGA Display Module

- System Compatibility: Bently Nevada 3500 Series Machinery Protection System

- Function: Provides real-time visual display of machine data, events, and alarms

- Key Components: 3500/94M VGA Module, associated I/O module, and a separate VGA display monitor (e.g., 10″ or 15″ Advantech)

- Part Number (Module Only): 184826-01

Detailed Product Description

As an expert in machinery condition monitoring, I understand that having accurate data is vital, but being able to see that data clearly and concisely is equally important. The Bently 3500/94M 184826-01 is precisely designed for this purpose within the venerable Bently Nevada 3500 Series. It’s the critical link that translates complex vibration, temperature, and process variable data from the 3500 rack into a graphical, easy-to-interpret format for operators and engineers.

Think of it as the “dashboard” for your most critical rotating machinery. Without a module like the 3500/94M, you’d have to rely solely on software on a separate computer to interpret the raw data. This module brings that essential information right to the machine or control room, offering immediate visual feedback on machine health.

The Bently 3500/94M system typically consists of three main components:

- The 3500/94M VGA Display Module (184826-01) itself, which resides in a slot in the 3500 rack.

- An associated I/O Module that connects to the rear of the rack and handles the physical connections to the display.

- A VGA display monitor, often an industrial-grade touchscreen from a compatible manufacturer like Advantech (available in sizes like 10″ or 15″).

Real-Time Visualization and Customization:

The core function of this module is to provide real-time monitoring of all the critical data from your 3500 system. This includes:

- System Event List: A chronological record of all significant events within the 3500 system.

- Alarm Event List: Detailed information on all triggered alarms, helping operators quickly identify and respond to issues.

- All Module and Channel Data: Displays raw and processed data from every monitoring module and channel in the rack.

- Current Alarm Data (Quick View): A snapshot of active alarms for immediate awareness.

- Nine Custom Display Options: This is a powerful feature! Using the 3500 Rack Configuration Software, users can design up to nine personalized screens. This allows you to tailor the display to specific machine trains, highlight particular vibration measurements (like 1X filtered vibration or proximity probe gap values), or organize data in a way that’s most intuitive for your operators. This level of customization ensures that the most relevant information is always front and center.

Flexible Connectivity and Robust Design:

The 3500/94M supports flexible mounting options for the connected display, including face mount, rack mount, panel mount, or independent mount. It can be located up to 6 meters (20 feet) from the 3500 rack using standard VGA cables. For longer distances, a Keyboard Video Monitor (KVM) Extender can extend the display up to 10 kilometers (6.2 miles) using fiber optic cables, or shorter distances using CAT5 UTP. This is crucial for large plants where the control room might be far from the machinery.

Designed for industrial environments, the module and compatible displays are built to withstand harsh conditions, including wide operating temperatures and high humidity. Some displays are even certified for hazardous locations (e.g., Class I, Division 2). This ensures reliable performance in demanding applications where machinery protection is paramount.

Technical Specifications

Key Features and Advantages

- Comprehensive Data Visualization: Provides a clear, graphical representation of all critical machinery protection data, including vibration levels, alarm statuses, and system events. This makes it easy for operators to quickly assess machine health.

- Customizable Screens: The ability to configure up to nine custom display screens allows users to prioritize and organize information relevant to their specific machines or processes, improving operational efficiency and reducing information overload.

- Real-Time Monitoring at the Machine: By displaying data directly at the machinery or in a local control room, operators can react instantly to abnormal conditions, preventing minor issues from escalating into major problems.

- Enhanced Situational Awareness: With touch screen capabilities on compatible monitors, operators can interact directly with the display to navigate through data, acknowledge alarms, and gain deeper insights into machine behavior.

- Flexible Display Placement: The support for standard VGA cables and KVM extenders allows the display to be located far from the 3500 rack, accommodating various plant layouts and control room designs.

- Robust Industrial Design: Built to withstand demanding industrial environments, ensuring reliable performance and a long operational life in challenging conditions.

Application Areas

The Bently 3500/94M 184826-01 and its associated display are indispensable in any industry that relies on continuous, reliable operation of rotating machinery:

- Power Generation: Crucial for monitoring large steam turbines, gas turbines, generators, and balance-of-plant machinery in power plants to prevent costly downtime and ensure grid stability.

- Oil & Gas: Used in refineries, petrochemical plants, pipelines, and offshore platforms to monitor compressors, pumps, and other critical turbomachinery, ensuring safe and efficient operations.

- Chemical Processing: Essential for monitoring rotating equipment in chemical plants where machine failures can lead to hazardous situations or significant production losses.

- Pulp & Paper: Helps monitor large motors, fans, and pumps throughout the paper-making process, ensuring continuous production.

- Mining: Used for monitoring large crushing, grinding, and conveying equipment, helping to prevent unexpected breakdowns in harsh mining environments.

- Water & Wastewater Treatment: Applied to monitor large pumps and blowers in municipal water and wastewater facilities to ensure continuous service.

Related Products

The Bently 3500/94M 184826-01 works as part of a larger, integrated system. Here are some related components you’d typically find alongside it:

- Bently Nevada 3500 Series Monitors (e.g., 3500/42M, 3500/50, 3500/60, 3500/61, 3500/62): These are the core modules that acquire vibration, position, speed, temperature, and other process data from the machinery. The 3500/94M collects data from these.

- Bently Nevada 3500/15 Power Supply: Provides regulated power to the entire 3500 rack, including the 3500/94M.

- Bently Nevada 3500/20 Rack Interface Module (RIM): The central communication module for the 3500 system, facilitating data transfer between the monitors, the 3500/94M, and external systems like System 1 software.

- Bently Nevada 3500 Rack Configuration Software: This software is used to configure the 3500/94M, including setting up the custom display screens and defining what data is presented.

- Industrial VGA Touch Screen Monitors (e.g., Advantech FPM Series): The physical display unit that connects to the 3500/94M I/O module to visualize the data.

- Bently Nevada 3500/94M Display Router Box (e.g., 149356-01): An optional component that allows a single display to view data from up to four separate 3500 racks, reducing the number of required displays for large installations.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922