الوصف

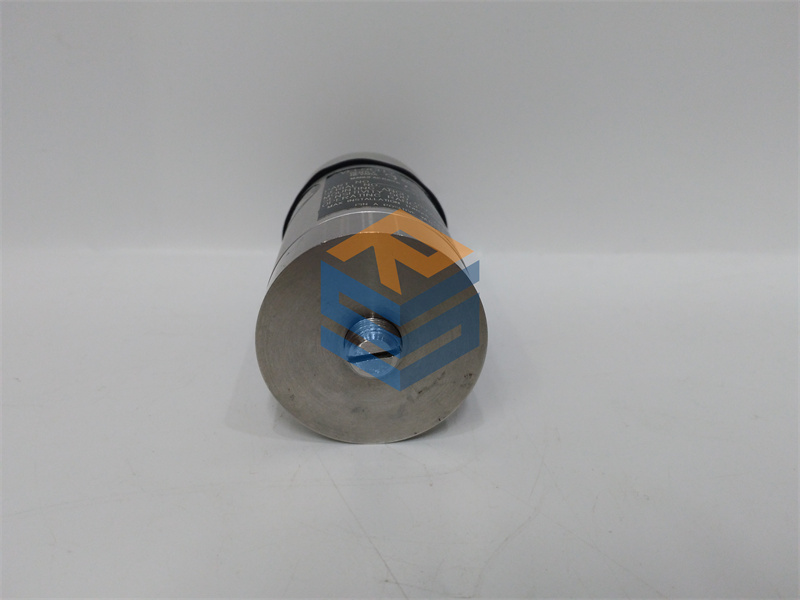

Product Name:

BENTLY 9200-01-01-10-00 DCS/PLC Module

Product Description:

The BENTLY 9200-01-01-10-00 is a high-performance Distributed Control System (DCS) and Programmable Logic Controller (PLC) module developed by Bently Nevada, a leading provider of condition monitoring and industrial automation solutions. Designed for industrial applications, the 9200 series is primarily used for vibration monitoring, process control, and diagnostics within critical machinery and equipment systems.

This module is designed to integrate seamlessly into an industrial environment, providing real-time data collection, monitoring, and analysis for mission-critical assets. The BENTLY 9200-01-01-10-00 is part of the 9200 series, which is renowned for its robust performance, scalability, and flexibility in demanding industrial settings.

The 9200-01-01-10-00 module offers enhanced monitoring capabilities, ensuring that the machinery operates within optimal parameters and triggering alarms when conditions deviate from the safe threshold. It is widely used in power plants, manufacturing, oil & gas, and other industries where continuous machinery performance is critical for operational safety and efficiency.

Product Parameters & Specifications:

General Specifications:

- Model: BENTLY 9200-01-01-10-00

- Type: DCS/PLC Module (Vibration Monitoring and Process Control)

- Application: Ideal for continuous machinery monitoring, vibration analysis, and process control.

- Compatibility: Compatible with Bently Nevada’s 9200 Series, integrates with existing DCS and PLC systems.

- Industry Usage: Used in oil & gas, power generation, manufacturing, mining, and other industries where machinery uptime is critical.

Electrical Specifications:

-

Input Voltage:

- 24V DC (nominal), with a wide operating range to accommodate varying industrial power setups.

-

Power Consumption:

- Approximately 3W-10W (depending on configuration and active functions).

-

Input/Output:

- Digital I/O: Supports various types of digital inputs and outputs for sensors, switches, and control systems.

- Analog I/O: Includes 4-20mA analog input/output options for vibration and temperature sensors.

-

Communication Interface:

- Modbus RTU or Modbus TCP for communication with a central control system or SCADA.

- Ethernet or RS-485 communication support for seamless data transfer.

- HART Protocol for advanced data monitoring and configuration.

-

Isolation:

- Optical Isolation for protection against electrical faults and ensuring reliable operation in harsh environments.

Mechanical Specifications:

-

Dimensions:

- Compact size for easy integration into standard industrial control panels.

- Approximate dimensions: 4.5″ H x 3.5″ W x 1.25″ D.

-

Mounting:

- DIN Rail Mountable, suitable for installation in industrial control enclosures or cabinets.

-

Enclosure:

- IP20 rated, providing protection against solid objects larger than 12mm but not rated for dust or water ingress.

-

Weight:

- Approx. 0.5 kg (1.1 lbs), lightweight for easy integration into existing systems.

Environmental Specifications:

-

Operating Temperature:

- -40°C to +70°C, ensuring reliable operation in extreme environmental conditions.

-

Storage Temperature:

- -40°C to +85°C, suitable for storage in a variety of conditions.

-

Humidity:

- 5% to 95% RH, non-condensing, allowing for operation in humid industrial environments.

-

Vibration Resistance:

- Designed to meet IEC 60068-2-6 standards, capable of withstanding typical industrial vibrations.

-

Shock Resistance:

- Withstands 10g shock (half-sine), ensuring durability in harsh environments.

Safety & Protection Features:

-

Surge Protection:

- Built-in surge protection to guard against voltage spikes and power surges.

-

Overvoltage Protection:

- Automatically protects sensitive electronics from excess voltage.

-

Overcurrent Protection:

- Overcurrent protection to ensure safe operation and prevent equipment damage from excessive current.

-

Short Circuit Protection:

- Integrated short circuit protection to ensure safety in case of wiring faults.

Diagnostic & Monitoring Features:

-

Condition Monitoring:

- Continuous monitoring of vibration, temperature, and other process parameters to ensure machinery is operating within optimal conditions.

-

Real-Time Data Acquisition:

- High-speed data acquisition and processing for critical machinery and equipment.

-

Alarming and Alerts:

- Configurable alarms and notifications for early detection of faults, enabling predictive maintenance.

-

Status Indicators:

- LED status indicators for power, communication, and fault status for quick diagnosis and troubleshooting.

Certifications & Compliance:

-

Certifications:

- CE certified, compliant with European safety standards.

- UL certified, meeting safety requirements for industrial applications.

-

EMC Compliance:

- Designed to meet IEC 61000-4-2 for immunity to electrostatic discharge and IEC 61000-4-3 for immunity to radiated radio-frequency electromagnetic fields.

-

Safety Standards:

- Compliant with ISO 9001 quality management standards.

Key Features:

-

Continuous Machinery Monitoring:

- Ideal for applications requiring vibration and condition monitoring of rotating machinery.

-

Flexible I/O Options:

- Supports digital and analog inputs/outputs for diverse sensor integration.

-

Communication Protocols:

- Supports Modbus RTU, Modbus TCP, Ethernet, and RS-485 communication interfaces for seamless integration into existing systems.

-

Advanced Diagnostics:

- Provides real-time data on machine condition, with alarm settings to alert operators to potential failures.

-

Durable in Harsh Environments:

- Designed to operate in extreme temperatures and resistant to shock and vibration.

-

Low Power Consumption:

- Energy-efficient design, consuming 3W-10W depending on configuration.

-

Remote Monitoring:

- Enables remote monitoring and management via Modbus or Ethernet interfaces.

-

Compact and Easy Installation:

- DIN Rail mountable for easy integration into control panels and automation systems.

Applications:

-

Vibration Monitoring:

- Ideal for continuous vibration monitoring of pumps, motors, turbines, and other rotating equipment.

-

Condition Monitoring:

- Essential for predictive maintenance in industries like oil & gas, power generation, and manufacturing.

-

Process Control:

- Used in applications where continuous monitoring of process parameters like temperature and vibration is critical.

-

Energy Management:

- Supports energy monitoring systems that optimize performance and reduce downtime.

-

Remote Diagnostics:

- Used in remote monitoring setups to provide continuous performance data for critical industrial machinery.

Conclusion:

The BENTLY 9200-01-01-10-00 DCS/PLC Module offers a reliable and robust solution for condition monitoring and process control in industrial applications. With its high precision, real-time data collection, flexible communication interfaces, and built-in protection features, it ensures that critical machinery operates smoothly, reducing downtime and preventing costly failures. Its compact design, durability, and easy integration into existing systems make it an ideal choice for industries such as oil & gas, power generation, manufacturing, and more.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922