الوصف

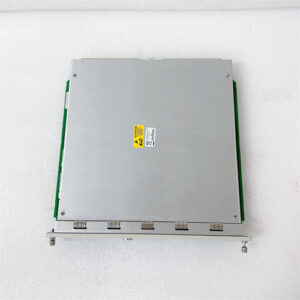

Product Name:

Bently Nevada 106M1081-01 DCS PLC Module

Product Description:

The Bently Nevada 106M1081-01 is a Distributed Control System (DCS) and Programmable Logic Controller (PLC) module used in industrial automation for monitoring, control, and protection of machinery. It is part of the Bently Nevada portfolio, a leading brand under Emerson focused on providing machinery health management and condition monitoring solutions.

This module is designed to interface with a variety of industrial sensors and monitoring equipment, making it ideal for critical operations in industries such as oil & gas, power generation, chemical processing, and manufacturing. The 106M1081-01 enables real-time monitoring, alarming, and protection for equipment, ensuring machinery uptime, preventing failure, and optimizing maintenance schedules through predictive analytics.

By integrating into a DCS or PLC system, this module helps operators ensure efficient, safe, and cost-effective management of complex industrial processes. It is also well-suited for large-scale facilities where real-time, reliable data is essential for maintaining peak performance.

Product Parameters & Specifications:

Module Type:

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) Module

- Manufacturer: Bently Nevada (Emerson)

- Model/Part Number: 106M1081-01

- Series: Bently Nevada Machinery Protection & Condition Monitoring

Input/Output Configuration:

- Digital Inputs (DI): Typically 8-32 digital inputs for various equipment monitoring, such as on/off signals from field devices.

- Digital Outputs (DO): Typically 8-32 digital outputs for control signals to actuators and alarms.

- Analog Inputs (AI): 4-8 analog inputs, typically used for monitoring process variables like vibration, temperature, and pressure.

- Analog Outputs (AO): Typically 2-4 analog outputs used for controlling equipment based on the monitored conditions.

Note: The exact number of I/O channels can vary depending on specific configurations and the system setup.

Communication Protocols:

- Modbus RTU/TCP: Integration with Modbus for communication with other devices in industrial networks.

- PROFIBUS/PROFINET: Compatible with PROFIBUS and PROFINET fieldbus protocols for communication with various automation systems.

- Ethernet/IP: Provides communication through Ethernet/IP networks for seamless data transfer in Ethernet-based environments.

- HART: Supports the HART protocol for integration with smart field devices such as transmitters and sensors.

Control and Performance:

- Real-Time Monitoring: Provides real-time monitoring and control, especially for machinery health and process optimization.

- Processing Speed: Built for high-speed processing to handle critical monitoring tasks with minimal latency.

- Data Logging: Capable of logging performance data and providing trend analysis to assist in predictive maintenance.

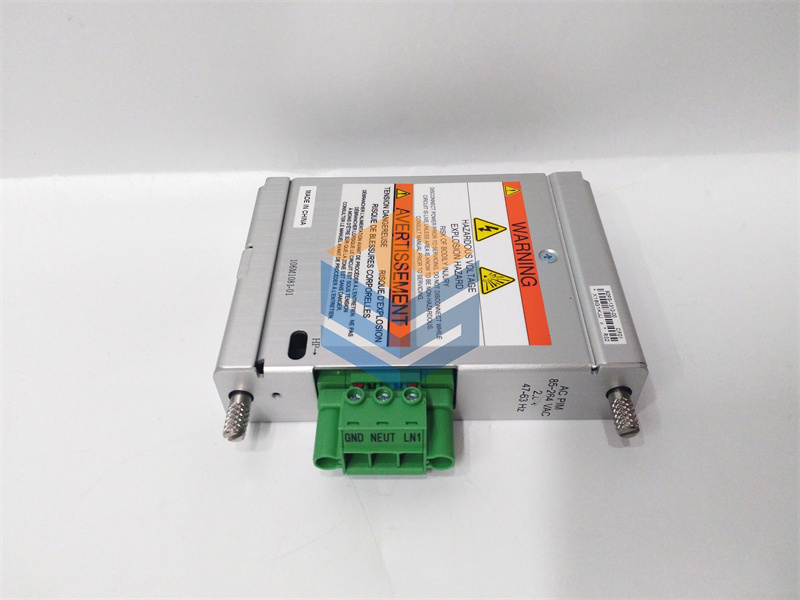

Power Supply:

- Operating Voltage: Typically 24 V DC for compatibility with industrial control systems.

- Power Consumption: Designed to operate with minimal power consumption to ensure system efficiency.

Environmental Specifications:

- Operating Temperature: Typically -20°C to +60°C (-4°F to +140°F), suitable for use in harsh industrial environments.

- Storage Temperature: -40°C to +85°C (-40°F to +185°F), allowing for safe storage even in extreme conditions.

- Humidity: Designed to function within a 5% to 95% relative humidity range (non-condensing).

- Vibration Resistance: Built to withstand industrial levels of vibration to ensure long-term reliability in dynamic settings.

Redundancy & Reliability:

- Redundant Power Supply: The module supports redundant power supply configurations to enhance system reliability.

- Failover Capabilities: Built-in failover mechanisms to minimize downtime and ensure continuity of critical processes.

- Self-Diagnostics: Includes diagnostic functions to detect faults early, reducing the likelihood of unexpected failures.

Safety & Compliance:

- Safety Integrity Level (SIL): Meets SIL 2 or higher safety standards, depending on configuration, for critical protection applications.

- Certifications: Typically meets CE, UL, and other international safety and compliance certifications for use worldwide.

- International Standards: Compliant with IEC 61508 for functional safety and IEC 61511 for safety instrumented systems (SIS).

Software & Programming:

- Software Compatibility: Designed to work seamlessly with Bently Nevada software tools and industrial automation platforms, such as Emerson PlantWeb.

- Programming Language: Supports standard industrial programming languages (e.g., IEC 61131-3), enabling flexible system configuration and control.

- Integration Tools: Compatible with Emerson’s AMS Suite for integrated condition monitoring, diagnostics, and predictive maintenance.

Diagnostics & Monitoring:

- Machinery Protection: Provides real-time protection against abnormal operating conditions such as excessive vibration, temperature, or pressure.

- Alarm & Notification: Capable of generating alarms for potential equipment failures, enabling immediate corrective action by operators.

- Performance Data Logging: Logs and stores data for trend analysis, supporting predictive maintenance strategies.

Key Features & Benefits:

-

Comprehensive Machinery Monitoring:

- Monitors a wide range of machinery parameters, including vibration, temperature, pressure, and other critical equipment performance metrics.

-

Predictive Maintenance:

- Provides early warning signals for potential equipment failure, helping prevent unplanned downtime and extending the life of critical machinery.

-

Integration with DCS/PLC Systems:

- Seamlessly integrates into existing DCS and PLC systems, providing enhanced capabilities for machinery protection and process optimization.

-

Flexible Communication Protocols:

- Supports multiple communication protocols (e.g., Modbus, PROFIBUS, Ethernet/IP, HART) to ensure compatibility with various industrial systems.

-

Redundancy & Reliability:

- Redundant power supply and failover mechanisms ensure system reliability and prevent downtime in critical operations.

-

Real-Time Data Processing:

- Provides real-time data processing and feedback, enabling operators to make informed decisions and take immediate corrective actions.

-

Condition-Based Monitoring:

- Provides continuous, condition-based monitoring to enhance the reliability of machinery and avoid unexpected failures.

-

Advanced Diagnostics and Alarming:

- Features advanced diagnostics and real-time alarming, allowing operators to receive instant notifications about system health and anomalies.

-

Industry-Leading Safety Standards:

- Meets industry-leading safety standards (e.g., IEC 61508, SIL certifications) for protection applications, ensuring high safety levels.

Applications & Use Cases:

- Power Generation: Ideal for monitoring turbines, generators, and other critical power plant machinery, providing continuous condition monitoring and protection.

- Oil & Gas: Used for machinery protection and predictive maintenance in offshore platforms, refineries, and pipeline systems.

- Chemical Processing: Suitable for monitoring pumps, compressors, and reactors in chemical plants, ensuring continuous and safe operation.

- Manufacturing: Enhances machinery protection and process control in manufacturing plants, helping improve operational efficiency and reduce downtime.

- Mining: Critical for monitoring mining equipment, such as crushers, conveyors, and mills, to ensure safe and continuous operation.

Conclusion & Recommendation:

The Bently Nevada 106M1081-01 DCS PLC Module is a robust and reliable solution for machinery protection, real-time monitoring, and predictive maintenance in critical industrial environments. With its advanced diagnostics, real-time data processing, and support for multiple communication protocols, this module is ideal for use in industries such as oil & gas, power generation, chemical processing, and manufacturing. It is highly recommended for applications requiring high reliability, system uptime, and equipment protection.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922