الوصف

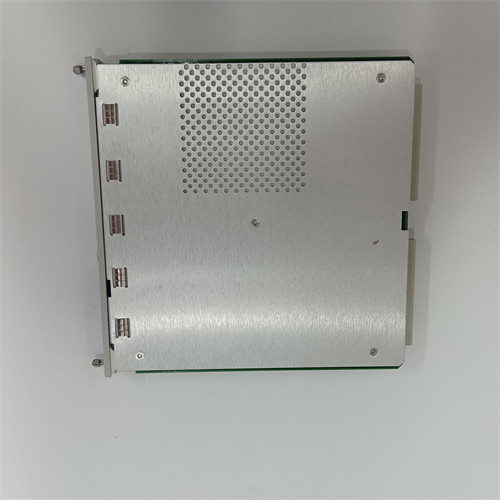

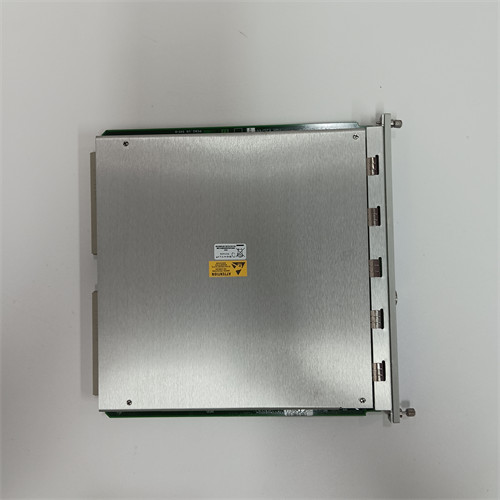

Product Name

BENTLY NEVADA 3500/20

Product Description

The BENTLY NEVADA 3500/20 is a highly advanced machinery protection and monitoring system designed for critical applications. It serves as a pivotal element in safeguarding machinery integrity, providing continuous real-time data collection and analysis to ensure optimal performance. This model combines the strengths of Bently Nevada’s long-standing expertise in condition monitoring and analysis equipment. The BENTLY NEVADA 3500/20 is equipped with customizable parameters, adaptable to various operational environments, ensuring reliable performance across multiple industries.

Product Parameters

- Model: BENTLY NEVADA 3500/20

- Input Channels: Up to 16 vibration measurement channels

- Sensor Compatibility: Proximity probes, acceleration sensors

- Data Sampling Rate: 1 kHz or higher

- Communication Protocol: Ethernet, Serial (RS-485), Modbus

- Operating Temperature Range: -40°C to +70°C

- Power Supply Voltage: 90-260 Vac or 24 Vdc

Advantages and Features

The BENTLY NEVADA 3500/20 boasts several advantages:

- Robust Construction: Designed to withstand harsh industrial environments.

- Flexible Configuration: Customizable inputs and outputs to match specific monitoring needs.

- Real-Time Monitoring: Provides immediate feedback on machinery performance, allowing for rapid response to anomalies.

- User-Friendly Interface: Intuitive software for configuration, monitoring, and analysis, enhancing user experience.

Application Areas and Case Studies

The BENTLY NEVADA 3500/20 is widely utilized in various sectors, including:

- Power Generation

- Oil and Gas

- Mining and Metals

- Manufacturing

A notable case study involves a power plant utilizing the BENTLY NEVADA 3500/20 to monitor turbine performance. By implementing this system, the plant achieved a 25% reduction in downtime, demonstrating the effectiveness of real-time monitoring in maximizing productivity.

Competitor Comparison

When comparing the BENTLY NEVADA 3500/20 to other market players such as SKF and Siemens, several key aspects stand out. While SKF offers high-quality monitoring solutions, the BENTLY NEVADA 3500/20 provides more extensive customization options and superior data accuracy. Siemens, although reputable, may lack the same level of specialized features designed for intricate machinery conditions that the BENTLY NEVADA 3500/20 excels in.

Selection Recommendations

For optimal results and reliability, the BENTLY NEVADA 3500/20 is recommended for facilities with critical machinery requiring advanced protection and condition monitoring. It is ideal for users looking for a durable solution that provides extensive reporting features and robust performance.

Precautions

When implementing the BENTLY NEVADA 3500/20, consider the following precautions:

- Ensure compatibility with existing machinery and sensors.

- Regularly update software to leverage the latest features and security improvements.

- Conduct routine maintenance to maintain optimal sensor performance.

We are your trusted partner, providing sales and technical support for the BENTLY NEVADA 3500/20 and other automation spare parts. Exclusive discount prices are available. Please contact us, and we will be pleased to serve you!

BENTLY NEVADA+3500/20

| REXROTH CLM01.4-N-E-2-B-FW |

| SIEMENS 6SE7023-8TD61-Z+G91 PLC |

| ENTERASYS A4H124-24FX PLC |

| GE IS220PTURH1A PLC |

| SIEMENS 6RA7000-0MV62-0 PLC |

| GE IC698CPE030 PLC |

| A-B 6181X-12A2SW71DC PLC |

| Indramat TVD1.3-15-03 PLC |

| SIEMENS 6SN1146-1BB02-0CA1 PLCCPU |

| ABB 5SHY3545L0010 PLC |

| ABB REM620E_FNBMNAAAANDA1BBN1XF PLC |

| REXROTH A11VL0260DRG/11R-NDD12N00 PLC |

| JOHNSON MS-NAE5510-2 7.0 PLCI/O |

| WOODWARD 9907-164 PLC |

| SIEMENS 6AV6644-7AA20-0BV0 PLC |

| ABB ACS880-01-240A-5+D150+E201+B056 PLC |

| GE IC698CPE030 PLC |

| TRICONEX 3008 PLC |

| TRICONEX 3625 PLC |

| SIEMENS 6AV6644-0AB01-2AX0 PLC |

| ABB SPIET800 PLC |

| GE IC698CPE030-GJ |

| A-B MPL-B860D-SJ72AA PLC |

| SIEMENS 6SE6430-2AD38-8FA0 PLC |

| Motorola MVME162PA-344SE PLC |

| Siemens 1LE15012CA233AB4 PLC |

| GE DS200DCFBG1B PLC |

| PIONEER MAGNETICS PM33988-6P-1-3P-E |

| Siemens 1FT6108-8AF71-1EA0 |

| GE IS420UCSBH1A |

| TRICONEX 3721 |

| MOTOROLA VMIVME 2540-000 |

| GE 369B1860G0026 |

| TEGAM 2350 |

| ESP302 EMERSON |

| VME-AD16 EMERSON PLC |

| VME-ADTH16 EMERSON |

| VME-ASI016 EMERSON |

| EMERSON VME-CAN2 |

| VME-DAC812 EMERSON PLC |

| EMERSON VMIE-CAN2 |

| VME-DAC812 EMERSON PLC |

| VME-IGC-2M / EMERSON |

| VME-ACRTC-21 EMERSON |

| EMERSON VME-IGP PLC |

| VME-IPOS-2 EMERSON |

| VME-1SEK12 EMERSON |

| EMERSON VME-ISER8 PLC |

| VME-PMC-CADDY/2 EMERSON |

| VME -PMC- CADDY/2plus EMERSON |

| VME-PMC-CPU/2 EMERSON |

| VME-PMC-CPU/2- CC EMERSON PLC |

| Komatsu E-332B-6 |

| A-B 1326AB-B515G-M2K5L |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922