الوصف

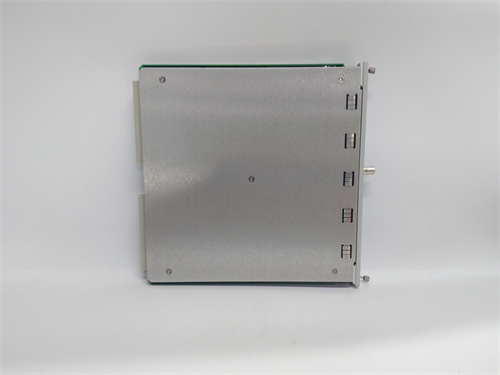

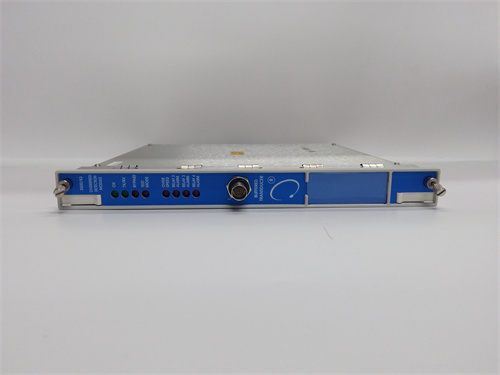

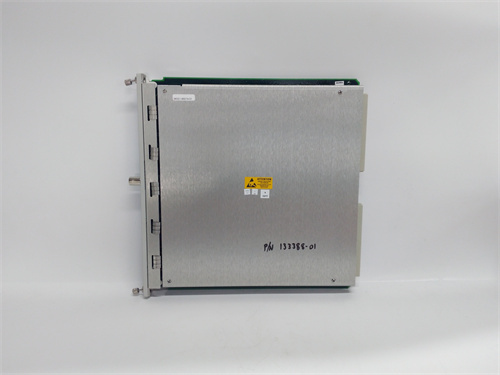

Product Name

Bently Nevada 3500/50M 286566-02

Product Description

The Bently Nevada 3500/50M 286566-02 is a highly reliable and sophisticated monitoring system designed for the protection and monitoring of critical machinery. As part of the Bently Nevada 3500 Series, this model specializes in providing advanced vibration monitoring, allowing for accurate measurement and analysis of rotational equipment. The 3500/50M delivers real-time data that aids in preventive maintenance and minimizes downtime, which is essential for organizations that rely on continuous operations.

Product Specifications

The Bently Nevada 3500/50M 286566-02 boasts several key specifications that enhance its functionality:

- Input Channels: Up to 8 channels for expanded monitoring

- Signal Processing: Advanced software algorithms for vibration analysis

- Operating Temperature: Ranges from -40°C to +70°C (-40°F to +158°F)

- Power Supply: 24V DC standard, with options for redundancy

- Connectivity: Standard TCP/IP and MODBUS protocols for easy integration

- Certification: CE and UL Certified for safety and performance compliance

Advantages and Features

The Bently Nevada 3500/50M 286566-02 offers numerous advantages that contribute to its popularity in the automation sector:

- High Accuracy: Provides precise vibration measurements that ensure machinery is operating within safe parameters.

- Real-time Monitoring: Facilitates immediate alerts for early detection of potential machinery failures.

- User-Friendly Interface: The system is equipped with an intuitive interface that simplifies operation and reduces training time for personnel.

- Scalability: Can be expanded conveniently as monitoring needs grow, suitable for both small and large organizations.

Application Areas and Case Studies

The Bently Nevada 3500/50M 286566-02 is utilized across numerous industries, including:

- Oil and Gas: Protecting pumps and compressors from vibrations that could indicate wear or failure.

- Power Generation: Monitoring turbines and generators to ensure reliability and efficiency.

- Manufacturing: Implemented in production lines for critical equipment monitoring.

- Water and Wastewater Management: Used in various applications to ensure pump reliability and prevent service interruptions.

Case studies have shown dramatic reductions in maintenance costs and operational disruptions in plants utilizing the 3500/50M, emphasizing its effectiveness.

Competitive Comparison

When comparing the Bently Nevada 3500/50M 286566-02 to other models on the market, such as Emerson’s AMS 6500 or Siemens’ Simocode, it consistently stands out for:

- Enhancement in Signal Processing: The 3500/50M utilizes advanced real-time analytics, providing better insights than competitors.

- User Integration: Superior ease of integration with existing systems compared to others in its class.

- Durability: Known for its robustness in harsh environments, making it more suitable for demanding situations.

Selection Advice

When choosing the Bently Nevada 3500/50M 286566-02, consider the following factors:

- Machinery Needs: Assess the specific monitoring requirements for your machinery to determine the necessary number of input channels.

- Integration Plans: Identify existing systems to ensure hassle-free integration.

- Budget: While the initial investment may be significant, the long-term savings on maintenance and downtime provide great value.

Precautions

It is crucial to consider the following points when using the Bently Nevada 3500/50M 286566-02:

- Regular Calibration: To ensure accuracy, the system should be regularly calibrated according to manufacturer guidelines.

- Environment Suitability: Verify that the operating environment meets the temperature and humidity specifications to prevent equipment malfunction.

- Software Updates: Keep the system’s software up to date to take advantage of the latest features and security enhancements.

We are your trusted partner in automation solutions, providing comprehensive sales and technical support for product models and other automation spare parts. Enjoy special discount prices! Please contact us, and we will be dedicated to serving you with the utmost care. (Product model: Bently Nevada 3500/50M 286566-02)

Bently Nevada+3500/50M 286566-02

| CC-TDIL11 |

| CC-TDOB01 DCS |

| CC-TDOB11 |

| FC-QPP-0002 |

| FF-SB12E04K-S2 |

| FF-SB12R04K-S2 I/O |

| J-DIM00 |

| J-MHM10 |

| J-MSC10 DCS |

| MC-TAMR04 I/O |

| TC-0AV081 |

| TC-CCR014 I/O |

| TC-FPCXX2 |

| TC-IAH161 |

| TC-OAV081 |

| TC-ODK161 |

| TC-PRR021 PLC |

| TC-PRS021 DCS |

| TC-XXX1 |

| TK-FXX102 PLC |

| TK-PRR021 PLC |

| TK-PRS021 |

| 0-51378-25 PLC |

| FBMSVH PLC |

| 0-57C400-A |

| 0-57C401-2 PLC |

| 0-57C402-C PLCCPU |

| 0-57C404-1E I/O |

| 0-57C405-C CPU |

| 0-57C406-E PLC |

| 0-57C407-4H PLC |

| 0-57C408-B PLC |

| 0-57C411-2 PLC |

| 0-60002-6 PLC |

| 0-60007-2 PLC |

| 0-60010-E |

| 0-60021-4 PLC |

| 0-60023-5 PLC |

| 0-60028-2 PLC |

| 0-60029-1 PLC |

| 0-60031-5 PLC |

| 0-60063-1 PLC |

| 10VV1/F7252 PLC |

| 30V4060 I/O |

| 45C220B DCS |

| 57045 PLC |

| 57401 PLC |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922