الوصف

Product Name

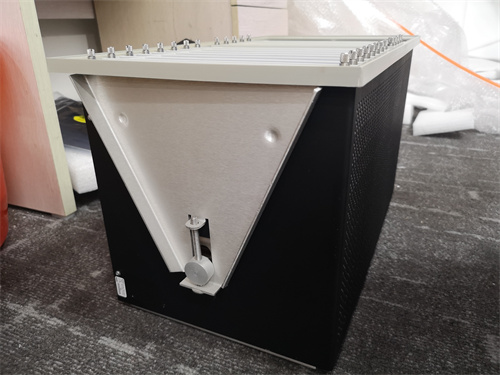

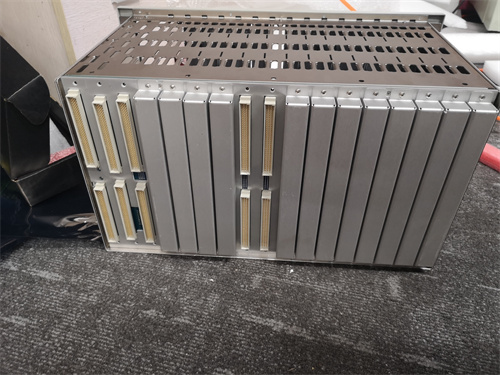

BENTLY NEVADA 3500 System Machinery Condition Monitor Modular Rack-based Design

Product Description

The BENTLY NEVADA 3500 System Machinery Condition Monitor is a sophisticated, modular rack-based monitoring solution for various machinery conditions. It is specifically designed to provide real-time, continuous monitoring of machinery’s health, ensuring operational efficiency and minimizing unplanned downtime. This system leverages state-of-the-art technology to deliver comprehensive data analysis, enhancing decision-making processes within industries that rely heavily on mechanical systems.

The BENTLY NEVADA 3500 offers multiple monitoring functions tailored for various machinery types, making it an indispensable tool for proactive maintenance strategies. The modular design allows for easy scalability and customization based on the user’s specific monitoring needs, ensuring maximum flexibility and efficiency.

Product Specifications

- Monitoring Channels: Up to 32 channels

- Input Types: Vibration, temperature, and other customizable inputs

- Communication Protocols: Ethernet, RS-232/RS-485, and more

- Power Supply: 24 VDC

- Temperature Operating Range: -40°C to +85°C

- Mounting Options: Rack-mounted or standalone

- Display Interface: User-friendly LCD screen with intuitive navigation

Advantages and Features

- Modular Design: The BENTLY NEVADA 3500 features a modular architecture that allows users to configure and expand their monitoring capabilities without major system overhauls.

- Real-Time Monitoring: Provides real-time data and alarms, enabling quick response to potential issues before they escalate into serious problems.

- Scalability: As operational needs grow, the system can be scaled to monitor additional equipment with minimal hassle.

- Comprehensive Analysis: Advanced diagnostic tools are included for detailed analysis, making it easier to identify root causes of machinery issues.

- Integration: Seamlessly integrates with existing control systems and networks, ensuring compatibility and ease of use.

Application Areas and Case Studies

The BENTLY NEVADA 3500 is mainly used in industries such as oil and gas, power generation, mining, and manufacturing. For example, in a power generation plant, this system was implemented to monitor turbine health, resulting in a 25% reduction in unplanned downtime due to early detection of potential mechanical failures.

In the oil and gas sector, corporations have utilized the BENTLY NEVADA 3500 to monitor pumping stations, ensuring reliable operation and maintenance schedules based on actual equipment conditions rather than arbitrary time schedules.

Competitive Comparison

When compared to other monitoring systems, such as those from Schneider Electric or Yokogawa, the BENTLY NEVADA 3500 stands out with its superior modularity and expansive monitoring options. Competitors often offer less flexible solutions, which can lead to higher costs and longer downtime during upgrades.

Selection Advice

When choosing a monitoring system, consider the complexity of your operations and specific machinery needs. The BENTLY NEVADA 3500 is highly recommended for applications that require extensive monitoring capabilities and scalability. Thoroughly define your monitoring objectives to select the best configuration for your needs and maximize the effectiveness of the system.

Considerations

It is essential to ensure compatibility with existing systems and infrastructure during installation. Additionally, training for personnel on how to utilize the BENTLY NEVADA 3500 effectively will maximize the benefits of this sophisticated monitoring solution.

We are your trusted partner, providing the BENTLY NEVADA 3500 model and other automation spare parts along with sales and technical support. We offer special discount pricing to help you achieve your automation goals. Please contact us; we are here to serve you diligently.

BENTLY NEVADA+3500 System Machinery Condition Monitor Modular Rack-based Design

| JANCD-FC230B PLC |

| JANCD-FC300B YASKAWA |

| JANCD-YCP01A PLC |

| R10092-718 YASKAWA |

| jancd-mi003 PLC |

| JANCD-FC510 DCS YASKAWA |

| JANCD-FC200 PLC |

| JANCD-MIO04 PLC YASKAWA |

| JANCD-FC190 PLC YASKAWA |

| JANCD-CG27 PLC |

| JANCD-MIF01 PLC |

| JANCD-MCP01 YASKAWA |

| JANCD-SP04 PLC |

| JANCD-MSV02 PLC |

| JANCD-MB21 PLC YASKAWA |

| JANCD-FC900C PLC |

| JANCD-FC310 PLC |

| JANCD-FC191 PLC |

| DF9201893-A0N PLC YASKAWA |

| JANCD-JCP04 YASKAWA |

| JANCD-MEW02 PLC YASKAWA |

| JANCD-PC20 PLC O |

| JANCD-BB03 |

| JANCD-XCP01 PLC |

| JANCD-MRY01B PLC |

| JANCD-GMR22 DCS YASKAWA |

| JANCD-NCP01 PLC YASKAWA |

| JANCD-MCP10 DCS |

| JANCD-SP20B PLC YASKAWA |

| JANCD-MM20 DCS YASKAWA |

| JANCD-GSC02 PLC YASKAWA |

| JANCD-MTV01 PLC |

| JANCD-GIF02 PLC |

| JANCD-FC211 PLC |

| JANCD-MIO03 PLC |

| JANCD-YBB02 PLC |

| JANCD-FC620 PLC |

| JANCD-MB22 PLC |

| JANCD-10O3E PLC |

| MM01C-02 PLCCPU |

| JANCD-XBB01 PLC |

| JANCD-GSR01 YASKAWA PLC |

| JANCD-CP03B PLC |

| JANCD-HA03 PLC |

| JANCD-MEW01 PLC |

| JANCD-MB20E PLC |

| JANCD-XEW02 PLC |

| JANCD-SV02B PLC |

| jancd-ycp01 PLC |

| JANCD-I PLC |

| JANCD-1006 DCS YASKAWA |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922