الوصف

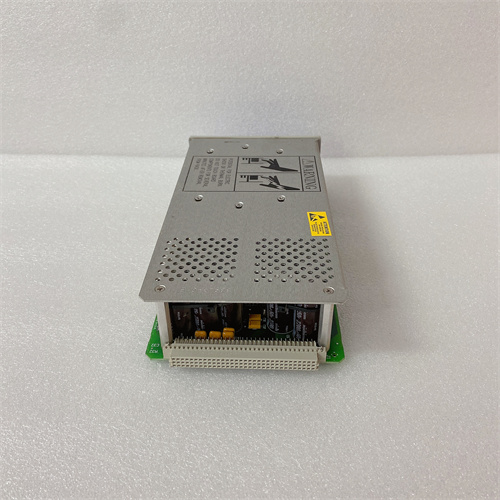

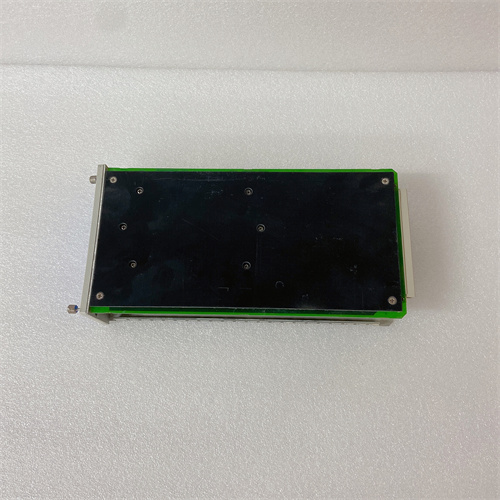

BENTLY 3500/15 133292-01

Product Description

The BENTLY 3500/15 133292-01 is a high-performance monitoring system designed specifically for critical machinery and industrial applications. This advanced component forms part of the BENTLY 3500 series and is renowned for its reliability and precision in monitoring vibration and dynamic parameters. Utilizing sophisticated algorithms, the BENTLY 3500/15 133292-01 provides real-time data, ensuring optimal performance and safety of various machinery.

Product Specifications

- Model: BENTLY 3500/15 133292-01

- Measurement Capabilities: Vibration monitoring, dynamic balancing

- Input Channels: Configurable, typically up to 4 channels

- Output: 4-20 mA, discrete alarms

- Power Supply: 120/240 VAC or 24 VDC

- Temperature Range: -40°C to +70°C

- Installation: Rack-based modular design

- Compliance: CE, UL

Advantages and Features

The BENTLY 3500/15 133292-01 is equipped with advanced diagnostic capabilities that enhance predictive maintenance strategies. Its key features include:

- High accuracy in vibration analysis

- Easy integration with existing control systems

- User-friendly interface for setup and monitoring

- Modular design promoting flexibility in system upgrades

- Robust construction ensuring longevity in harsh industrial environments

Application Areas and Case Studies

The BENTLY 3500/15 133292-01 is widely used in various industries, including:

- Oil and Gas: For monitoring pumps, compressors, and turbines to prevent failures.

- Power Generation: Essential in turbines and generators for real-time performance evaluation.

- Manufacturing: Used in rotating machinery to detect imbalances and prevent potential breakdowns.

One notable case involved a power plant enhancing their monitoring system with the BENTLY 3500/15 133292-01, leading to a 30% reduction in unplanned downtime by implementing predictive maintenance based on the real-time data provided by the system.

Competitor Comparison

When compared to equivalent products from competitors such as SIEMENS and ABB, the BENTLY 3500/15 133292-01 stands out in terms of its robustness and advanced monitoring capabilities. While competitors may offer similar functionalities, the BENTLY system is often preferred for its ease of use, flexibility, and superior reliability in high-stakes environments.

Selection Recommendations

When selecting the BENTLY 3500/15 133292-01, consider the following:

- Assess the specific monitoring needs of your application.

- Ensure compatibility with the existing control and monitoring systems.

- Evaluate the environmental conditions where the equipment will be installed.

BENTLY+3500/15 133292-01

| SAFT-168PAC ABB PLC |

| ABB SAFT192POW PLC |

| ABB DSAI133 PLC |

| USART86 ABB PLC |

| SAFP25PAN ABB PLC |

| P350/070 PLC |

| SAMT 11 ABB |

| ABB SAFT121PAC DCS |

| SAFT120 PAC ABB PLC |

| ABB SAFT171 PAC PLC |

| ABB SAFT187 CON PLC |

| SAFT110POW ABB PLC |

| SAFT190 APC plc |

| DSTD108L plccpu |

| SAFT136 CTS dcsplc |

| TC530 ABB DCS |

| ABB DSTD-W150 PLC |

| ABB DSTA155 PLC |

| DSPC155 ABB PLC |

| ABB SAFT192POW PLC |

| SAFT170 PAC ABB PLC |

| SAFT111POW PLC |

| ABB SAFT169 PAC PLC |

| ABB SAFT185TBC PLC |

| ABB TKAA2136 PLC |

| TKAAC9270 ABB IO |

| ABB FDIV8CH PLC |

| ABB IOD86MEM PLC |

| GKKA2121G011 |

| GKKAC7689 |

| IOD86-TR PC |

| CPU86-10MHZ+S100M PLC |

| GTO1300V880A PLCCPU |

| SAFT100F380 PLC |

| SAFT063F 380 |

| AI086-8/4 PLC |

| A1086-8/4 PLC |

| ABB SNAT607MCI PLC |

| PM633 DCS |

| ABB TU810V1 |

| IMASI23 DCS |

| IMRIO02 ABB I/O |

| ABB IMDSO14 PLC |

| ABB DSMB175 PLC |

| YPK112A ABB plcplc |

| ABB ES300-9643 plc |

| ABB NTCL01-A plc |

| ABB BC810K02 plc |

| SM811K01 |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922