الوصف

Product Name

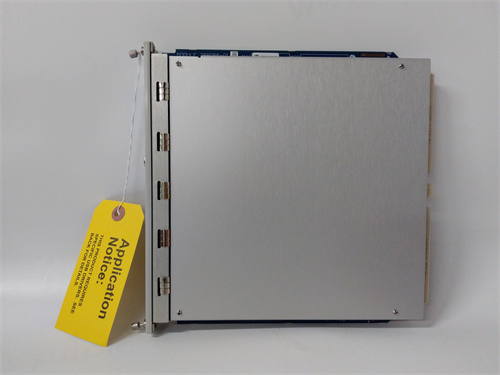

BENTLY 3500/20

Product Description

The BENTLY 3500/20 is a powerful and essential component in the realm of industrial automation and condition monitoring. This model functions as a vibration monitor designed to enhance the reliability and efficiency of rotating machinery. The BENTLY 3500/20 provides critical insights into machine health, enabling timely intervention and maintenance. This monitor is equipped with extensive diagnostic capabilities, allowing operators to track performance and detect anomalies in real time.

Product Specifications

- Model: BENTLY 3500/20

- Input Type: Vibration sensors (including accelerometers)

- Power supply: 24 VDC

- Mounting: Standalone or integrated into the 3500 rack system

- Communications: Supports Ethernet and serial connections

- Operating Temperature: -40°C to +65°C

- Condition Monitoring: 4-channel vibration monitoring

- Weight: Approximately 1.4 kg (3 lb)

Advantages and Features

The BENTLY 3500/20 boasts several advantages and features that set it apart from other monitors. Firstly, its robust design ensures high durability and longevity, making it suitable for harsh industrial environments. Furthermore, the monitor supports advanced analytics capabilities, allowing users to perform trend analysis and predictive maintenance, which reduces unplanned downtime. The BENTLY 3500/20 also integrates seamlessly with existing automation systems, ensuring ease of installation and operational compatibility.

Applications

The BENTLY 3500/20 is widely utilized in various industries including oil and gas, power generation, and manufacturing. It is particularly effective for monitoring critical machinery such as turbines, compressors, and pumps, where vibration analysis can provide early warnings of potential issues.

Case Studies

For example, in a power generation facility, the implementation of the BENTLY 3500/20 significantly reduced downtime by identifying a developing fault in a turbine well before it incurred any severe damage, thus saving both time and repair costs.

Competitor Comparison

When comparing the BENTLY 3500/20 with competitor products like the Siemens SITRANS or the SKF Multilog series, it is evident that the BENTLY 3500/20 offers superior accuracy and more extensive diagnostics options. The built-in capabilities for integration with PLCs and HMI systems further enhance its usability, positioning it as a leader in the vibration monitoring market.

Selection Recommendations

When selecting a vibration monitor, consider factors such as the specific machinery to be monitored, the operating environment, and the necessary communication interfaces. If your operation values detailed diagnostics and predictive maintenance capabilities, the BENTLY 3500/20 is a highly recommended choice.

Precautions

While using the BENTLY 3500/20, ensure proper installation to avoid inaccuracies caused by environmental interference. Regular calibration and system checks are also advisable to maintain optimal performance.

We are your trusted partner, providing sales and technical support for the BENTLY 3500/20 and other automation spare parts. We are pleased to offer you special discount prices. Please contact us for dedicated service.

BENTLY+3500/20

| MVME162-522A PLC |

| MVME162-533A PLC |

| MVME162P242E PLC |

| MVME162PA-344SE |

| MVME165-03 |

| MVME166-012A |

| MVME166-11A |

| MVME167 I/O |

| MVME167-01A |

| MVME167-01B DCS |

| 210105 DCS |

| 210240 |

| 8901037 |

| 1751-6091 |

| 9907-167 |

| 1904-72 DCS |

| 2301D DCS |

| 2301D-ST |

| 240128A 740545B |

| 27G50F-5F06-999 I/O |

| 364437 PG-PL I/O |

| 5059907-164 |

| 5418-151 |

| 5431-528 dcs |

| 5437-055 DCS |

| 5437-687 I/O |

| 5437-845 |

| 5439-730 |

| 5439-929 |

| 5441-407 |

| 5441-611 |

| 5441-669 |

| 5441-693 DCS |

| 5446-348 |

| 5453-203 |

| 5453-276 DCS |

| 5453-279 |

| 5456-676 |

| 5463-550 PLC |

| 5463-780 |

| 5463-783 PLC |

| 5463-785 |

| 5463-786 PLC |

| 5463-880 PLC |

| 5463-882 I/O |

| 5464-213 |

| 5464-331 |

| 5464-334 DCS |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922