الوصف

Product Name

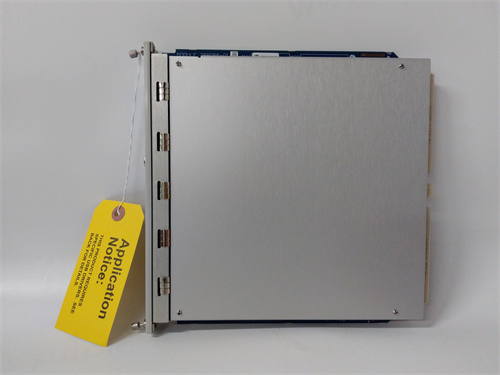

BENTLY 3500/22M

Product Description

The BENTLY 3500/22M is a high-performance vibration monitoring system designed specifically for the continuous monitoring of the mechanical condition of rotating machinery. This advanced system is part of the BENTLY 3500 series, which combines state-of-the-art technology with robust reliability. The 3500/22M module allows for comprehensive vibration analysis, ensuring your equipment runs at optimal performance while minimizing risk.

Product Specifications

- BENTLY+3500/22M

- Input Channels: 4 channels of vibration monitoring

- Power Supply: 24 VDC

- Operating Temperature Range: -40°C to +70°C

- Weight: 1.2 kg

- Dimensions: 10.16 cm x 25.4 cm x 23 cm

- Communication Interface: Communication via BENTLY 3500 Rack Interface

- Certification: CE, UL, CSA approved

Advantages and Features

The BENTLY 3500/22M module offers several key advantages and features:

- Precision Monitoring: Provides accurate vibration measurements which enable early detection of potential issues.

- Flexibility: Can be integrated into various system setups, accommodating a wide range of applications.

- User-Friendly Interface: The intuitive design allows for easy installation and maintenance.

- Robustness: Built to withstand challenging environments while maintaining consistent monitoring performance.

- Real-Time Data Analysis: Offers real-time data streaming, enhancing decision-making processes for maintenance and operations.

Application Fields and Case Studies

The BENTLY 3500/22M is suitable for various industries, including:

- Oil and Gas: Utilized in monitoring pumps, compressors, and turbines to reduce downtime and prevent failures.

- Power Generation: Effective in safeguarding critical machinery in power plants.

- Manufacturing: Ensures the operational integrity of production equipment, increasing productivity.

- Aerospace: Applied in safety-critical environments for vibration monitoring of aircraft engines.

Case studies show that facilities using the BENTLY 3500/22M have reported a significant decrease in unscheduled maintenance and improved machine uptime due to enhanced monitoring capabilities.

Competitive Comparison

Compared with other vibration monitoring systems such as the EMERSON NETA and SKF IMx-1, the BENTLY 3500/22M excels in:

- Data Accuracy: Offers higher precision in measuring vibration levels.

- Integration: More compatible with existing automation frameworks.

- User Support: BENTLY provides extensive support and maintenance services tailored to client needs.

Selection Advice

When choosing the BENTLY 3500/22M, consider the following factors:

- The complexity of your machinery applications.

- The need for real-time monitoring vs periodic checks.

- Integration capability with existing systems.

- Your budget for vibration monitoring solutions.

It is advisable to consult with a specialist to ensure the BENTLY 3500/22M is the right solution for your specific needs.

Precautions

When implementing the BENTLY 3500/22M, consider the following safety and operational precautions:

- Ensure installation complies with local electrical and environmental safety standards.

- Regularly calibrate the system to maintain its high accuracy.

- Take care during installation to prevent damage to the module or surrounding machinery.

We are your trusted partner, providing sales and technical support for the BENTLY 3500/22M and other automation spare parts. We offer special discounted prices for you. Please contact us; we are dedicated to serving you.

BENTLY+3500/22M

| MVME167-01B DCS |

| 210105 DCS |

| 210240 |

| 8901037 |

| 1751-6091 |

| 9907-167 |

| 1904-72 DCS |

| 2301D DCS |

| 2301D-ST |

| 240128A 740545B |

| 27G50F-5F06-999 I/O |

| 364437 PG-PL I/O |

| 5059907-164 |

| 5418-151 |

| 5431-528 dcs |

| 5437-055 DCS |

| 5437-687 I/O |

| 5437-845 |

| 5439-730 |

| 5439-929 |

| 5441-407 |

| 5441-611 |

| 5441-669 |

| 5441-693 DCS |

| 5446-348 |

| 5453-203 |

| 5453-276 DCS |

| 5453-279 |

| 5456-676 |

| 5463-550 PLC |

| 5463-780 |

| 5463-783 PLC |

| 5463-785 |

| 5463-786 PLC |

| 5463-880 PLC |

| 5463-882 I/O |

| 5464-213 |

| 5464-331 |

| 5464-334 DCS |

| 5464-337 DCS |

| 5464-346 i/o |

| 5464-355 PLC |

| 5464-414 PLC |

| 5464-444 PLC |

| 5464-458 PLC |

| 5464-468 |

| 5464-541 PLC |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922