الوصف

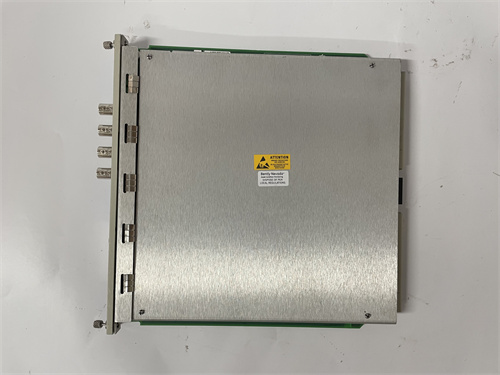

Product Name

BENTLY+3500/42M 176449-02 140734-99

Product Description

BENTLY 3500/42M is a high-performance monitoring system designed for the protection and management of critical assets in various industrial applications. This model is a part of the renowned BENTLY 3500 series, which is well-regarded for its reliability and advanced diagnostic capabilities. The 3500/42M specifically excels in monitoring machinery vibration, providing real-time data that is essential for maintaining the health of rotating equipment.

The BENTLY 3500/42M delivers outstanding performance with its features that include high-speed data acquisition, comprehensive signal conditioning, and intelligent monitoring functions. It is also equipped with advanced alarm capabilities, ensuring that operators are immediately notified of any abnormal conditions.

Product Specifications

- Model: BENTLY+3500/42M 176449-02 140734-99

- Measurement Channels: Multi-channel support for extensive monitoring

- Signal Input: Supports various signal types including 4-20 mA and voltage inputs

- Operating Temperature Range: -40 to 70 degrees Celsius

- Power Supply Voltage: 20-30 VDC

- Weight: Depends on the configuration chosen

- Digital Display: User-friendly interface for easy parameter setting and monitoring

- Communication Interface: Supports multiple protocols for integration with PLC systems

Advantages and Features

The BENTLY 3500/42M stands out due to its:

- High Accuracy: Offers precise readings critical for predictive maintenance.

- Versatile Compatibility: Easily integrates with existing automation systems and various PLCs.

- Robust Design: Built to withstand harsh industrial environments.

- Comprehensive Diagnostics: Advanced algorithms to analyze machine health and predict failures.

- User-Friendly Interface: Simplifies setup and monitoring for users.

Application Fields

The BENTLY 3500/42M is widely used across several industries, including:

- Oil and Gas: Essential for monitoring rotating machinery in extraction and processing.

- Manufacturing: Assists in safeguarding critical equipment in production lines.

- Power Generation: Vital for monitoring turbines and generators.

- Water Treatment: Ensures the reliability of pumps and other essential machinery.

Application Cases

One notable application of the BENTLY 3500/42M was in an oil refinery where it was employed to monitor gas compressors. The system facilitated the early detection of vibration anomalies, allowing for proactive maintenance and averting costly downtimes.

Competitive Comparison

When compared to its competitors, such as the Schneider Electric Modicon systems and Siemens S7 series, the BENTLY 3500/42M offers superior vibration monitoring capabilities and more extensive diagnostic features. Its reputation in the field for reliability sets it apart from other products in the same category.

Selection Recommendations

When choosing the BENTLY 3500/42M, consider your specific application needs, such as the number of channels required and the types of signals your machinery uses. Ensure compatibility with your existing PLC and automation systems for seamless integration.

Important Notes

While the BENTLY 3500/42M is engineered for durability, proper installation and regular maintenance are vital to ensure optimal performance. Always consult the user manual and follow manufacturer guidelines during installation and use.

We are your trusted partner, providing sales and technical support for the BENTLY 3500/42M, and other automation spare parts. We offer special discount prices for you. Please contact us, and we will be dedicated to serving you.

BENTLY+3500/42M 176449-02 140734-99

| EMERSON KJ3243X1-BB1 |

| EMERSON KJ3244X1-BA1 |

| KJ4001X1-BA1 EMERSON |

| EMERSON KJ4001X1-BA2 |

| KJ4001X1-BA3 EMERSON |

| EMERSON KJ4001X1-BB1 |

| EMERSON KJ4001X1-BE1 |

| EMERSON KJ4001X1-BH1 DCSPLC |

| MERSON KJ4001X1-CA1 |

| EMERSON KJ4001X1-CB1 DCSPLC |

| EMERSON KJ4001X1-CC1 |

| EMERSON KJ4001X1-CD1 |

| EMERSON KJ4001X1-CE1 |

| EMERSON KJ4001X1-CF1 |

| EMERSON KJ4001X1-CG1 DCSPLC |

| EMERSON KJ4001X1-CH1 |

| KJ4001X1-CJ1 EMERSON |

| EMERSON KJ4001X1-DG1 |

| EMERSON KJ4001X1-EA1 |

| EMERSON KJ4001X1-GA1 |

| EMERSON KJ4001X1-GG1 |

| KJ4001X1-HA1 EMERSON |

| EMERSON KJ4001X1-JA1 |

| EMERSON KJ4001X1-NA1 |

| EMERSON KJ4001X1-NB1 |

| EMERSON KJ4002X1-BA1 |

| EMERSON KJ4002X1-BB1 DCSPLC |

| EMERSON KJ4002X1-BC2 |

| EMERSON KJ4002X1-BD2 |

| EMERSON KJ4002X1-BE1 DCSPLC |

| EMERSON KJ4002X1-BF1 |

| EMERSON KJ4002X1-BF2 |

| EMERSON KJ4003X1-BA1 |

| EMERSON KJ4003X1-BB1 |

| EMERSON KJ4003X1-BC1 |

| EMERSON KJ4003X1-BD1 |

| EMERSON KJ4003X1-BE1 |

| EMERSON KJ4003X1-BF1 DCSPLC |

| EMERSON KJ4003X1-BG1 |

| EMERSON KJ4003X1-BH1 |

| EMERSON KJ4010X1-BF1 |

| EMERSON KJ4010X1-BG1 |

| EMERSON KJ4020X1-BD1 |

| EMERSON KJ4110X1-BA1 |

| EMERSON KJ4110X1-BC1 |

| EMERSON KJ6001X1-BA2 |

| EMERSON KJ6001X1-CA2 |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922