الوصف

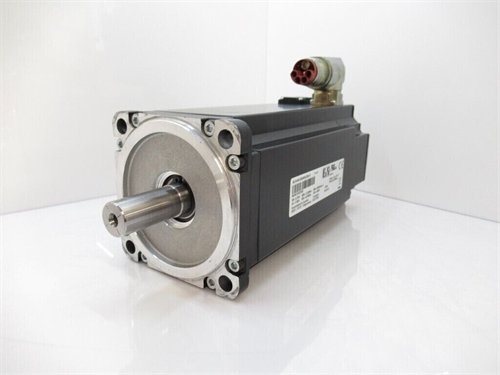

The B&R 8LSA34.DB030S100-3 is a synchronous servo motor from B&R’s 8LS series, featuring an integrated holding brake and a specific encoder type. It’s designed for high-precision, dynamic motion control applications, particularly where load holding is required.

B&R 8LSA34.DB030S100-3: Synchronous Servo Motor with Holding Brake (Size 3)

This part number precisely defines a specific configuration within B&R’s 8LS synchronous motor series. These motors are known for their compact design, high power density, and excellent dynamic performance. The “34” in the part number indicates a smaller frame size (Size 3) compared to the “44” or “55” models, making it suitable for applications with lower torque requirements but still demanding precision.

Key Specifications and Features:

- Type: Synchronous Servo Motor

- Manufacturer: B&R Automation (now part of ABB)

- Series: 8LS

- Frame Size: Size 3 (indicated by “A34”). This is a smaller motor within the 8LS family, with a typical centering diameter of 80 mm for mounting.

- Rated Speed: 3000 RPM (revolutions per minute).

- Nominal Torque: Typically around 2.1 Nm (Newton-meters) for comparable models in this size.

- Stall Torque: Around 2.3 Nm.

- Nominal Current: Around 1.4 A.

- Stall Current: Around 1.6 A.

- Maximum Torque: Can reach up to 9.2 Nm.

- Maximum Current: Up to 6.8 A.

- Maximum Speed: Can reach up to 9000 RPM.

- Voltage: Operates at 400 V.

- Shaft: Smooth shaft. While some DB models might have a key, common 8LS “DB” configurations are often with smooth shafts and a holding brake.

- Connectors: Features angled swivel connectors, providing flexibility for cable routing.

- Brake: The “DB” in the part number explicitly indicates that this motor includes a holding brake.

- Holding Torque of Brake (MBr): For a size 3 motor (like an 8LSA34), the holding torque of the brake is typically 4 Nm. This brake is designed to hold the load in position when power is removed or during a stop, preventing unwanted movement.

- Protection Class: IP64, indicating it is protected against dust ingress and splashing water from any direction.

- Cooling: Self-cooling (construction type A), relying on natural convection for heat dissipation.

- Pole Pairs: Typically 4 pole pairs.

- Feedback System: The “S100” refers to the encoder system. For 8LS motors, “S” typically denotes a single-turn absolute encoder, often an EnDat inductive 32-line single-turn encoder. This provides precise position feedback within one revolution.

- Embedded Parameter Chip: B&R 8LS motors come with an embedded parameter chip within the encoder that stores all relevant mechanical and electrical information. This enables the paired B&R ACOPOS servo drive to automatically identify the motor and configure itself for optimal control, simplifying commissioning.

- Version: The “-3” typically indicates a specific version or revision of the motor.

Decoding the Part Number:

- 8LS: Denotes the 8LS Synchronous Motor series.

- A34: Specifies the motor type and dimensions (self-cooled, flange-mounted, Size 3).

- DB: Indicates the connection type and presence of a brake (angled swivel connectors, with brake).

- 030: Relates to the nominal speed (3000 rpm).

- S100: Specifies the integrated feedback system (single-turn absolute encoder).

- -3: Indicates the version or revision.

Typical Applications:

Given its combination of precision, dynamic response, and integrated holding brake, the B&R 8LSA34.DB030S100-3 is ideal for applications where:

- Vertical Axes with Smaller Loads: Holding lighter loads in position against gravity, such as in small lifting mechanisms or Z-axes in automation.

- Precision Positioning: Where the motor needs to accurately stop and hold a position without drift, even when power is off, in light-duty applications.

- Small Conveyor Systems: Requiring controlled stops and precise indexing.

- Assembly Machines: For precise part placement and holding.

- Robotics (smaller scale): In articulated arms for lighter payloads or in end-effectors where a brake is needed for safety or stability.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922