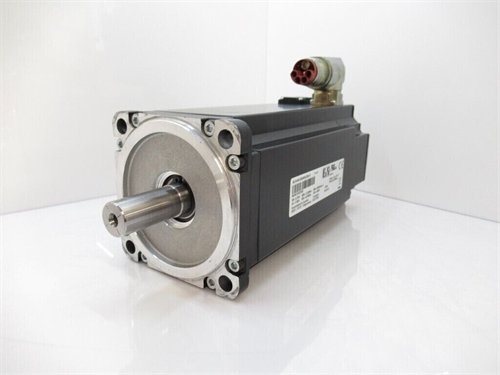

الوصف

B&R 8LSA44.EB030D100-3

The B&R 8LSA44.EB030D100-3 is a synchronous servo motor from B&R’s 8LS series. These motors are designed for high-precision, dynamic motion control applications in industrial automation.

B&R 8LSA44.EB030D100-3: Synchronous Servo Motor

This part number specifies a particular configuration within B&R’s 8LS synchronous motor series. These motors are known for their compact design, high power density, and excellent dynamic performance.

Key Specifications and Features:

- Type: Synchronous Servo Motor

- Manufacturer: B&R Automation (now part of ABB)

- Series: 8LS

- Frame Size/Design: The “44” in “8LSA44” indicates a specific frame size or motor design within the 8LS series.

- Rated Speed: Typically 3000 RPM (revolutions per minute).

- Nominal Torque: Around 4.6 Nm (Newton-meters).

- Stall Torque: Approximately 6 Nm.

- Nominal Current: Generally in the range of 2.8 to 3.7 Amps.

- Voltage: Operates at 400 V.

- Shaft: Smooth shaft, meaning it does not have a keyway or spline.

- Connectors: Features angled swivel connectors, providing flexibility for cable routing.

- Protection Class: IP64, indicating it is protected against dust ingress and splashing water from any direction.

- Pole Pairs: Typically 5 pole pairs.

- Centering Diameter: 95 mm (for mounting).

- Feedback System: While not explicitly stated in the brief snippets, B&R 8LS motors usually come with an integrated feedback system (e.g., encoder) for precise position and speed control when paired with a compatible servo drive.

- Brake: The “EB” in the part number indicates it typically does not include a brake. If it had a brake, the code would usually be different (e.g., “DB”).

Decoding the Part Number (General 8LS Structure):

While the exact meaning of every character can be complex and specific to B&R’s internal coding, here’s a general breakdown that applies to similar 8LS part numbers:

- 8LS: Denotes the 8LS Synchronous Motor series.

- A44: Likely refers to the motor size, design, or performance class.

- EB: Often indicates the connection type and whether a brake is present (e.g., “EA” for smooth shaft, angled connector, no brake; “EB” for similar configuration; “DB” for brake). In this case, “EB” suggests angled swivel connectors and no brake.

- 030: Could relate to the nominal speed (e.g., 3000 rpm).

- D100: Could denote specific encoder or feedback system details (e.g., 100 might refer to a specific encoder resolution).

- 3: Often indicates the version or a specific variant.

Typical Applications:

B&R 8LS synchronous servo motors are widely used in various industrial automation applications requiring precise, dynamic, and reliable motion control. These include:

- Packaging Machinery: For precise positioning, cutting, sealing, and handling.

- Machine Tools: In applications where accurate linear or rotary movements are critical, such as CNC machines.

- Robotics: For articulated arms and end-effectors where high torque density and dynamic response are needed.

- Printing Presses: For precise registration and web handling.

- Textile Machinery: In various processes requiring accurate material feeding and positioning.

- Material Handling Systems: In conveyors, pick-and-place units, and automated storage and retrieval systems.

- Food and Beverage Processing: Where hygiene, speed, and precise movements are essential.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922