الوصف

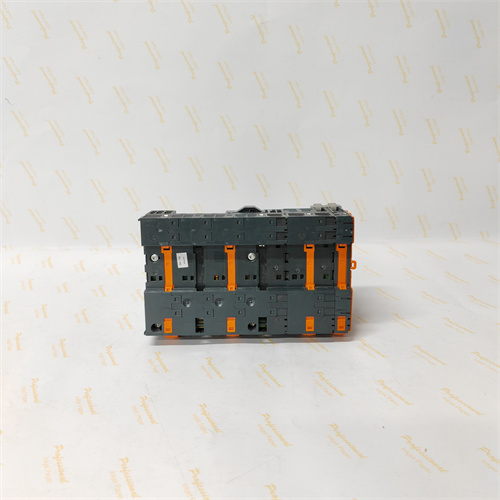

The B&R 5AP933.215C-00 is part of the B&R Automation series, a leading manufacturer of industrial automation systems, including programmable logic controllers (PLC) and Distributed Control Systems (DCS) components. The 5AP933.215C-00 module is specifically designed to support automation in various industrial applications, offering high-performance control, integration flexibility, and advanced diagnostic capabilities.

Here’s the detailed product information for the B&R 5AP933.215C-00 DCS PLC Module:

Product Name

- B&R 5AP933.215C-00 DCS PLC Module

Product Description

The B&R 5AP933.215C-00 module is a Digital I/O interface for the Automation Studio system, designed to serve as an essential component in industrial automation and process control applications. It provides reliable digital input and output interfaces to integrate field devices, enabling precise real-time control. The 5AP933.215C-00 is part of B&R’s modular approach to process automation, offering flexible scalability and high communication capabilities.

With high-speed digital I/O handling and compatibility with B&R’s Automation Studio environment, this module is perfect for critical applications in industries such as manufacturing, energy, and process control. It supports various industrial protocols and is optimized for use in both small and large-scale automation systems.

Product Parameters & Specifications

- Model Number: B&R 5AP933.215C-00

- Type: Digital I/O Module

- Supply Voltage: 24V DC

- Operating Temperature Range:

- Standard: 0°C to 60°C

- Extended: -25°C to 70°C (optional versions may support extended temperature ranges)

- Input/Output Channels:

- Digital Inputs: 16 channels

- Digital Outputs: 16 channels

- Input Voltage Range: 24V DC (typical)

- Digital Input Signal Type:

- Dry Contact (e.g., NO/NC switches)

- Sensor Inputs: Compatible with standard 24V DC sensors

- Digital Output Signal Type:

- Relay Outputs (for switching higher current loads)

- Transistor Outputs (for low voltage control)

- I/O Processing Time:

- Input Processing: 1ms

- Output Processing: 1ms

- Communication Protocol:

- Ethernet/IP

- Powerlink (Real-Time Ethernet)

- PROFINET (optional, depending on configuration)

- Mounting Type: DIN Rail (Standard)

- Power Consumption: Approx. 4-6W (depending on configuration)

- Dimensions:

- Height: 100 mm

- Width: 150 mm

- Depth: 60 mm

- Weight: Approx. 0.5 kg

- Status Indicators:

- LED Indicators: For status of inputs, outputs, communication, and power

- Certifications:

- CE

- UL

- RoHS Compliant

- Industrial EMC (Electromagnetic Compatibility) compliant

Key Features

-

High-Speed Digital I/O: This module offers 16 digital input and 16 digital output channels, ensuring fast and reliable communication with field devices. It is suitable for applications that require precise control over on/off signals or switching operations.

-

Integrated Communication Protocols: The 5AP933.215C-00 supports Ethernet-based communication protocols like Ethernet/IP and Powerlink, enabling seamless integration into B&R’s distributed control system or other industrial networks. This feature is particularly useful for systems that require real-time control and high-speed data exchange.

-

Flexible I/O Configuration: With both transistor and relay outputs, the module can control a wide range of actuators and devices, including motors, valves, sensors, and more. The flexibility in output types makes it adaptable to various industrial control needs.

-

Modular Design: The B&R 5AP933.215C-00 module can be easily integrated into existing systems, with support for modular expansion and scalability. This makes it an ideal choice for growing applications or systems requiring high levels of customization.

-

Durable and Reliable: Designed to operate in harsh industrial environments, the 5AP933.215C-00 module is built to withstand temperature variations, vibrations, and electrical noise, ensuring long-lasting performance and reliability.

-

Real-Time Data Processing: With a processing time of 1ms for both inputs and outputs, the 5AP933.215C-00 provides real-time control, which is critical in fast-paced automation tasks.

-

Diagnostics and Maintenance: The B&R Automation Studio software integrates with the module, offering detailed diagnostic tools and data logging features to monitor system health, troubleshoot errors, and reduce downtime.

Applications and Use Cases

The B&R 5AP933.215C-00 is widely used in industries that require precision control, fast data exchange, and reliable automation systems:

- Manufacturing Automation: Used for controlling machines, conveyors, and assembly lines, this module ensures that digital input/output operations are executed with minimal latency.

- Process Control: In industries such as food and beverage, chemical, and water treatment, the module ensures accurate control of equipment such as pumps, valves, and sensors.

- Energy and Utilities: Employed for controlling and monitoring electrical circuits, equipment, and grid systems in power plants or substations.

- Automotive: The module is used in automotive manufacturing for controlling robots, assembly systems, and testing equipment.

- Building Automation: In facilities management, it can help automate lighting, HVAC systems, and security systems for improved energy efficiency and safety.

Comparison with Competing Products

The B&R 5AP933.215C-00 module stands out due to its flexible I/O configuration, support for Ethernet-based protocols (such as Powerlink and Ethernet/IP), and real-time processing capabilities. Compared to similar modules from other automation providers, the 5AP933.215C-00 offers faster data processing speeds and better scalability, making it a preferred choice for applications that require low latency and high integration flexibility.

While other competitors may provide digital I/O modules with similar specifications, the B&R 5AP933.215C-00 integrates smoothly with the B&R Automation Studio ecosystem, allowing for centralized management and easier system expansion. Additionally, its robust communication support enables it to fit into a wider range of industrial networks, ensuring seamless data transfer and operational efficiency.

Selection Tips and Considerations

- I/O Requirements: Ensure that the 16 inputs and 16 outputs offered by the 5AP933.215C-00 meet the specific needs of your automation system. If more I/O channels are required, consider expanding with additional modules or upgrading to a higher capacity model.

- Communication Protocol: Verify that the communication protocols supported (Ethernet/IP, Powerlink) are compatible with your existing network infrastructure or other automation systems you’re using.

- Environmental Conditions: While the module is suitable for most industrial environments, it is essential to assess the temperature, humidity, and electrical noise levels at the installation site to ensure optimal operation.

- Software Integration: The Automation Studio environment provides excellent integration capabilities, so ensure that your team is familiar with the software to maximize the system’s potential.

For more detailed product information or to inquire about pricing and availability, please visit www.br-automation.com or contact your local B&R distributor.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922