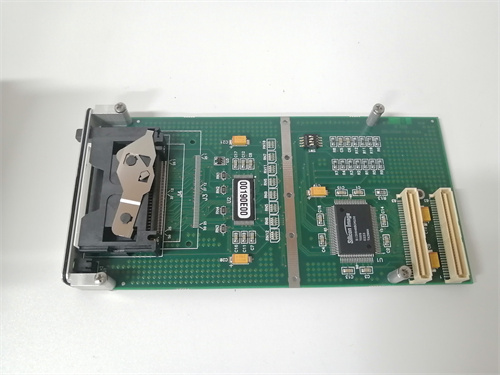

الوصف

Product Name

FORCE+PMC422FP

Product Description

The FORCE+PMC422FP is a sophisticated programmable logic controller (PLC) that excels in industrial automation applications. Designed by FORCE, this model integrates advanced features and technology to facilitate efficient control and monitoring of various automated systems. The FORCE+PMC422FP is engineered for applications that require robust performance, reliability, and scalability.

This innovative PLC offers features suited for both small and large operations, making it a versatile choice for different automation tasks. With support for various communication protocols and expansion capacities, the FORCE+PMC422FP is well-equipped to handle complex control strategies in dynamic environments.

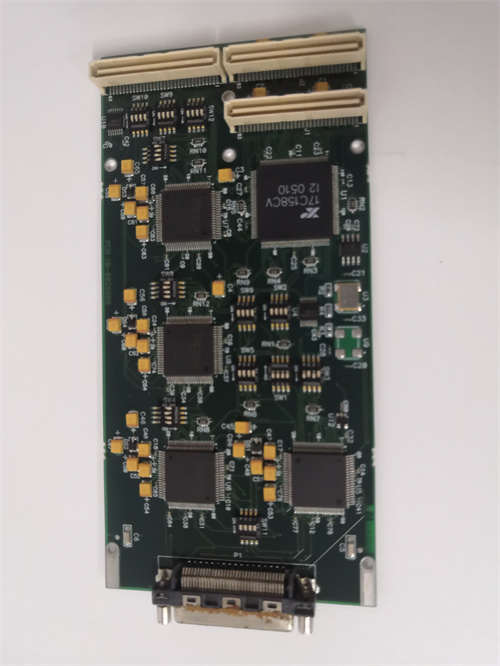

Product Specifications

- FORCE+PMC422FP

- Input Power: 24 VDC

- Input Channels: Up to 32 digital inputs

- Output Channels: Up to 32 relay outputs

- Communication Ports: RS-232, RS-485, Ethernet

- Programming Languages: Ladder Logic, Structured Text, Function Block Diagram

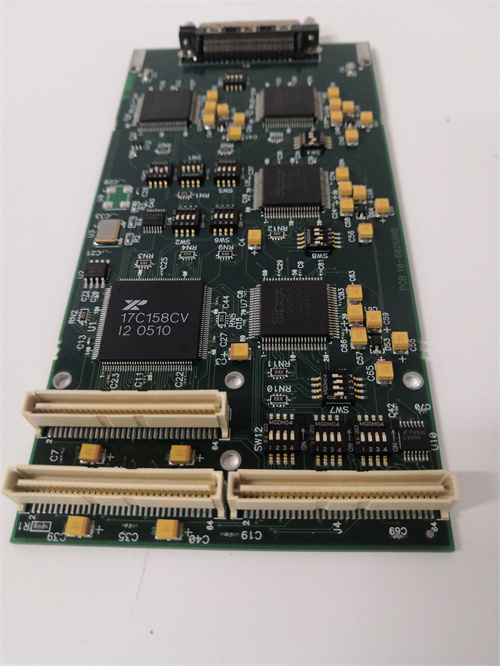

- Memory: 512 KB non-volatile memory

- Operating Temperature: -10°C to 60°C

- Dimensions: 200mm x 150mm x 100mm

Advantages and Features

The FORCE+PMC422FP stands out due to its robust features:

- High Versatility: It supports multiple programming languages, allowing users to select their preferred method for PLC programming.

- Expanded I/O Options: The ability to connect additional I/O modules enhances its adaptability to diverse operational needs.

- Reliable Communication: Equipped with various communication ports, it seamlessly integrates into existing systems, ensuring efficient data exchange.

- Compact Design: The compact form factor makes it suitable for tight spaces often found in industrial settings.

- User-Friendly Interface: The intuitive programming software simplifies setup and maintenance, reducing downtime.

Application Fields and Use Cases

The FORCE+PMC422FP is highly applicable in various segments such as:

- Manufacturing: Control and monitor production lines to enhance productivity and reduce waste.

- Food & Beverage: Manage bottling and packaging processes ensuring compliance with industry standards.

- Oil & Gas: Control and monitor extraction and refining processes, enhancing safety and efficiency.

- Water Treatment: Automate control systems for treatment plants to maintain performance and quality.

A notable use case of the FORCE+PMC422FP was seen in a manufacturing facility where it controlled an entire assembly line. The PLC significantly improved the operating efficiency by enabling real-time monitoring and adjustments to the production flow, resulting in reduced operational costs.

Competitor Comparison

In comparison with other PLCs like Siemens S7-1200 and Allen-Bradley Micro820, the FORCE+PMC422FP offers a unique combination of affordability and high functionality. While the Siemens model excels in scalability within larger systems and the Allen-Bradley series is known for its user-friendly interface, the FORCE+PMC422FP provides a favorable balance between cost and feature set, especially for mid-sized enterprises seeking reliability without excessive investment.

Selection Advice

When selecting the FORCE+PMC422FP, consider the following aspects:

- Application Requirements: Assess the scale and complexity of the tasks you intend to automate.

- Integration Needs: Ensure the PLC can communicate with existing systems and devices in your operations.

- Future Expansion: Choose the FORCE+PMC422FP if you plan to scale operations, as it supports additional I/O expansion.

- Technical Support: Look for suppliers that provide robust technical support and training for your team.

Precautions

While integrating the FORCE+PMC422FP into your systems, consider the following precautions:

- Power Supply: Ensure that the power supply meets the specifications to avoid potential damage.

- Environmental Conditions: Install the PLC in recommended temperature ranges to maintain performance.

- Proper Wiring: Follow wiring guidelines as outlined in the manual to prevent connection issues.

We are your trusted partner, providing sales and technical support for the FORCE+PMC422FP and other automation spare parts. Special discount prices are available. Please contact us, and we will be dedicated to serving you.

FORCE+PMC422FP

AB 1756-IM16I/A

A-B 1756-OB16E

NI SCXI-1300

Advantech PCA6186VE A1

ABB CI801

BENTLY 330106-05-30-10-02-00

A-B 1756-A10

A-B 1794-ACN15/D

A-B 1746-P2

FOXBORO P0916AE

AB 1746-A10

Honewell CC-TDOB01

AB 1771-A4B

ETHERWAN EL100T

A-B 1756-OW16I

ABB IMAS102

ABB 3HAB8101-11/05D

A-B 1791DS-IB12

NI SCXI-1300

A-B 1756-A7

A-B 22A-A2P3N114

ABB 3HAB8101-7/06B

ABB TTH300-Y0

NI SCXI-1326

ABB ACS510-01-025A-4

A-B 22A-A2P3N114

AB 1791-8BC

A-B 1771-0W16

NI SCXI-1327

A-B 1746-NI4

A-B 1756-A10

NI SCXI-1001

A-B 1756-OB32

BACHMANN RS204

GE IC670MDL331D

A-B 1747-L542维修费

NI UMI-7764

GE IC200MDL742G

REXROTH力士乐 VT 3002-1-2X/48F

A-B 1756-A13

SIEMENS 6ES7153-1AA03-0XB0

A-B 354792-A01 REV 02 0208

A-B 1756-A7/B

NI SCXI-1326

GE IC693ALG220

A-B 1746-P2

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922