الوصف

Sure, as a seasoned expert in industrial automation, I’m happy to help you with that. The FOXBORO FBM205 is a well-known component in the Foxboro I/A Series, and I can tell you a lot about it. It’s a voltage input module, crucial for bringing analog voltage signals from the field into your control system. Let’s get into the specifics.

You’re asking about another critical component in many industrial control systems: the FOXBORO FBM205. This module is designed to accurately read analog voltage signals from various field devices and integrate them into your Foxboro I/A Series Distributed Control System (DCS). Think of it as a highly sensitive voltmeter for your industrial process, converting those subtle voltage changes into usable data for your control system.

Let’s dive into the details.

SEO-Optimized Top 10 Titles:

- FOXBORO FBM205: 8-Channel Isolated Voltage Input Module (0-10V, 0-5V, 1-5V).

- Precision Voltage Monitoring: FOXBORO FBM205 for Foxboro I/A Series DCS.

- FBM205: High-Accuracy Isolated Analog Voltage Input Module.

- Enhance Process Measurement: FOXBORO FBM205 for Voltage Signals.

- Why Choose FOXBORO FBM205: Galvanic Isolation & Wide Input Range.

- FBM205: Essential Component for Industrial Automation Voltage Inputs.

- 8 Isolated Inputs, Configurable Ranges: Key Features of FOXBORO FBM205.

- FOXBORO FBM205: Ideal for Sensor Integration and Data Acquisition.

- Streamline Data Collection: FBM205 with Termination Assemblies for Field Devices.

- Robust & Versatile: FOXBORO FBM205 for Diverse Industrial Applications.

Brief Product Description:

The FOXBORO FBM205 is an 8-channel, galvanically isolated analog voltage input interface module designed for the Foxboro I/A Series and Compact 200 Series I/O subsystems. It accepts configurable voltage input ranges (e.g., 0-5 VDC, 1-5 VDC, 0-10 VDC) from various field transmitters and sensors, providing accurate and reliable measurements. With individual channel isolation and robust design, it ensures high data integrity and system stability for critical analog voltage inputs in demanding industrial environments.

- Product Type: Analog Voltage Input Module

- Channels: 8 isolated inputs

- Input Ranges: Configurable (e.g., 0-5 VDC, 1-5 VDC, 0-10 VDC)

- Isolation: Galvanically isolated for each channel

- Compatibility: Foxboro I/A Series, Compact 200 Series I/O

Detailed Product Description:

As an expert in the field, I often encounter situations where capturing precise voltage signals is absolutely crucial. Think about position transmitters on large valves, strain gauges, or specialized analytical instruments – many of these devices output their data as a voltage. If you can’t read these signals accurately and reliably, your entire control strategy could be compromised. That’s where the FOXBORO FBM205 steps in. This module is specifically engineered to handle these analog voltage inputs, acting as a highly accurate translator between your field devices and your Foxboro I/A Series Distributed Control System. It’s built for precision and resilience, which is exactly what you need in demanding industrial settings.

Core Features and Galvanic Isolation: Precision in a Noisy World

So, what makes the FOXBORO FBM205 such a valuable component in your automation architecture?

First off, it provides eight analog input channels. This channel density is quite practical for many applications, allowing you to connect multiple voltage-output sensors to a single module, which can simplify your wiring and reduce the overall footprint of your I/O racks.

The most critical feature, in my professional opinion, is the galvanic isolation for each individual input channel. This isn’t just a fancy term; it’s a fundamental requirement for reliable operation in industrial plants. Picture this: your plant floor is often a chaotic place, electrically speaking. You have large motors starting, variable frequency drives humming, and all sorts of electrical noise that can induce spurious voltages or create ground loops. If your input channels aren’t isolated, this electrical “noise” can bleed from one channel to another, or from the field directly into your control system, leading to inaccurate readings, erratic behavior, or even damaging sensitive electronics. With individual galvanic isolation, each channel is electrically separated, effectively creating a barrier that prevents these interferences. This ensures that the voltage signal you read is a true reflection of the process variable, untainted by external electrical disturbances. That translates directly into more stable control and far fewer headaches during troubleshooting.

The FBM205 is highly versatile because it supports multiple configurable voltage input ranges, typically including 0-5 VDC, 1-5 VDC, and 0-10 VDC. This flexibility means you can connect a wide array of industrial sensors without needing external signal conditioners, simplifying your design and reducing potential points of failure. The module also features high-resolution analog-to-digital converters (ADCs), often employing sigma-delta conversion technology, which ensures excellent accuracy and repeatability for your measurements. You’re getting extremely precise data from your field devices.

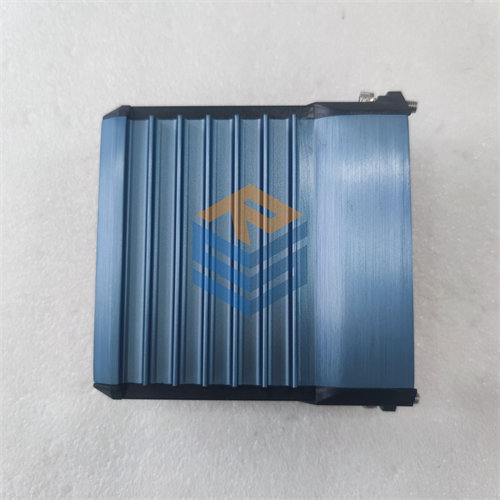

Furthermore, the FBM205 is constructed with a rugged design, often featuring an extruded aluminum housing, making it highly durable and suitable for harsh industrial environments. It typically meets environmental standards such as ISA Standard S71.04 Class G3 for resistance to airborne contaminants. It mounts on a standard Foxboro Compact 200 Series baseplate, which facilitates easy installation on DIN rails or in racks. Like other FBMs, it supports “hot-swapping,” meaning you can remove and replace the module without powering down the entire I/O subsystem, which significantly reduces maintenance time and improves system availability.

Finally, while the FBM205 does not inherently support redundancy at the module level (as it’s an input module), the overall Foxboro I/A Series architecture allows for system-level redundancy (e.g., redundant processors, redundant Fieldbus Communications Modules) that contribute to the high availability of the data acquired by the FBM205.

Technical Specifications:

Applications:

The FOXBORO FBM205 is deployed across a wide range of industries and applications where accurate voltage measurements are essential for process control and monitoring:

- Manufacturing and Assembly: Monitoring the position of actuators, robotic arm angles, or the output from vision systems that provide voltage signals. For instance, in an automated assembly line, an FBM205 might read the voltage output from a linear position sensor to precisely control the placement of components, ensuring consistent product quality.

- HVAC and Building Management: Measuring various environmental parameters like temperature (from specialized voltage-output sensors), humidity, or pressure in large commercial or industrial buildings. This allows for precise climate control and energy management.

- Test and Measurement Systems: In research and development or quality control labs within industrial settings, where precise voltage readings from custom sensors or test benches are needed to analyze material properties or product performance.

- Machine Monitoring and Diagnostics: Collecting data from vibration sensors, load cells, or specialized transducers that output voltage signals to assess the health and performance of rotating machinery or structural components. This supports predictive maintenance strategies.

- Renewable Energy (Solar/Wind): While often using digital communication, some older or simpler solar panel arrays or wind turbines might use voltage outputs for specific readings (e.g., cell voltage, battery bank voltage), which the FBM205 can effectively monitor.

Related Products:

The FOXBORO FBM205 works seamlessly within the Foxboro I/A Series architecture and can be complemented by or interchanged with various other modules depending on specific application needs:

- Foxboro FBM201 (P0914SQ): This is an 8-channel isolated analog input module for 0-20mA current signals. If your field devices output current rather than voltage, the FBM201 would be the appropriate choice. They often work in tandem on the same baseplate.

- Foxboro FBM202 (P0914TB / P0916AC): This is an 8-channel isolated thermocouple/mV input module. For direct temperature measurement using thermocouples or very low voltage (millivolt) signals, the FBM202 is specialized for those inputs.

- Foxboro FBM204 (P0914TC): A 4-channel isolated analog input/output module (0-20mA). While the FBM205 is input-only for voltage, the FBM204 offers both analog input and output capabilities for current signals.

- Foxboro FBM207 (Various P/Ns): Digital input modules (like FBM207B for 24VDC contact sense) are used for on/off signals. The FBM205 handles continuous analog voltage, while the FBM207 handles discrete states.

- Foxboro Field Control Processors (FCPs – e.g., FCP270, FCP280): These are the intelligent controllers that receive the data from the FBM205, execute control algorithms, and send commands to output modules.

- Foxboro Fieldbus Communication Modules (FCMs – e.g., FCM10E, FCM10EF): These modules manage the high-speed communication between the FBMs (including FBM205) and the FCPs or other control stations.

- Foxboro Termination Assemblies (TAs): These external panels provide the physical wiring interface for connecting field devices (like voltage-output sensors) to the FBM205 module, often including fuse protection or isolation points.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922