الوصف

Can you tell me what are the specific features and applications of the FOXBORO FBM211 module? What is the role of the FOXBORO FBM211 in a Foxboro I/A Series DCS? What are the technical specifications of the FOXBORO FBM211? FOXBORO FBM211 datasheet FOXBORO FBM211 manual FOXBORO FBM211 specifications As a seasoned expert in industrial automation, I can provide you with detailed information about the FOXBORO FBM211. This module is a core component within the Foxboro I/A Series Distributed Control System (DCS), specifically designed for high-density, accurate current input measurements.

The FOXBORO FBM211 is a 16-channel, 0-20 mA differential input interface module. It plays a critical role in bringing analog current signals from various field devices, such as transducers and transmitters, into the digital realm of the DCS for monitoring, control, and data acquisition.

SEO-Optimized Top 10 Titles:

- FOXBORO FBM211: 16-Channel 0-20 mA Differential Input Module for DCS.

- High-Density Analog Input: FOXBORO FBM211 for Foxboro I/A Series.

- FBM211: Precision Current Input Module with Group Isolation.

- Robust Process Monitoring: FOXBORO FBM211 in Harsh Environments.

- Why Choose FBM211: Accuracy, Configurable Options, and Seamless Integration.

- FOXBORO FBM211: Essential for SCADA, PLC, and DCS Systems.

- 16 Channels, Sigma-Delta Conversion, 2Mbps Fieldbus: Key Features of FBM211.

- FOXBORO FBM211: Ideal for Large-Scale Data Acquisition and Control.

- Streamlined Field Wiring: FBM211 with Dedicated Termination Assemblies.

- Enhanced Process Visibility: The Role of FOXBORO FBM211 in Industrial Automation.

Brief Product Description:

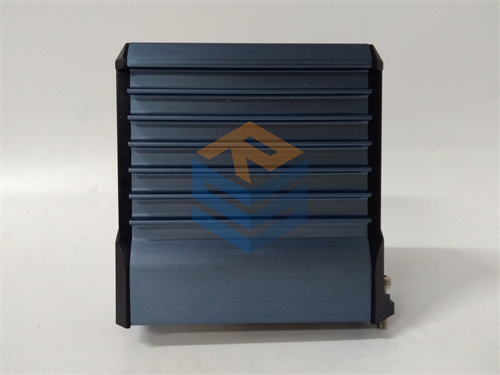

The FOXBORO FBM211 (P0914TN) is a 16-channel, 0-20 mA differential analog input interface module designed for Foxboro I/A Series and EcoStruxure Foxboro DCS. It accurately acquires current signals from 2-wire analog sensors, such as 4-20 mA transmitters or self-powered 20 mA sources. While channels are not individually isolated, they are group isolated from ground and module logic, providing robust noise immunity. It supports high-accuracy measurements via a multiplexed Sigma-Delta converter and offers configurable options for data conversion and rate-of-change limits. Its rugged design makes it suitable for harsh industrial environments.

- Product Type: Analog Current Input Module

- Channels: 16 differential inputs

- Input Range: 0-20.4 mA DC

- Isolation: Group isolated (from ground and module logic; not channel-to-channel)

- Compatibility: Foxboro I/A Series, EcoStruxure Foxboro DCS

- Common Part Number: P0914TN

Detailed Product Description:

As an expert in industrial control, I frequently deal with current-based signals (like 4-20 mA) because they are robust against noise over long distances, making them ideal for plant environments. The FOXBORO FBM211 is specifically designed to excel at acquiring these types of signals. It acts as a crucial interface, translating the continuous current measurements from your field instruments into digital data that your Foxboro DCS can understand and utilize for precise control and monitoring.

Core Features and Group Isolation: Capturing Critical Current Data

What makes the FOXBORO FBM211 a workhorse in industrial automation?

-

High-Density 16-Channel Input: The FBM211 provides a high number of input channels (16) within a single module. This density is beneficial for applications with many analog inputs, reducing the physical footprint of the I/O subsystem and simplifying cabinet design. It allows for efficient aggregation of current signals from numerous field devices.

-

0-20 mA Differential Input: It’s designed to accept standard 0-20 mA DC analog current signals. This includes the very common 4-20 mA signal, which is widely used in industrial instrumentation due to its inherent noise immunity and fault detection capabilities (a 0 mA signal indicates a broken wire or device failure). The differential input configuration helps to further reject common-mode noise, leading to cleaner and more accurate readings.

-

Group Isolation: While the 16 channels are not galvanically isolated from each other, they are group isolated from ground and the module’s internal logic. This means that an entire group of channels is isolated as a block from the common ground of the DCS. This provides a significant level of protection against ground loops and common-mode electrical noise originating from the field, which is vital for maintaining signal integrity and preventing damage to the module or the control system. The module can withstand a potential of 600 V AC applied for one minute between the group-isolated channels and earth (ground) without damage.

-

High Accuracy and Signal Conversion: For high accuracy, the FBM211 utilizes a multiplexed Sigma-Delta converter shared by all channels. This advanced A/D conversion technology provides high resolution and precision, ensuring that the digital representation of the analog signal is highly accurate. It can provide new analog input readings every 100 ms, and offers configurable integration periods to effectively filter out process noise and power line frequencies (50 or 60 Hz), resulting in stable and reliable measurements.

-

Configurable Application Program: The FBM211 executes an analog input application program that allows for configurable options such as:

- Conversion Time: Adjusting how frequently measurements are taken.

- Rate of Change Limits: Setting alarms or flags if an input changes too rapidly, indicating a potential process upset or sensor issue.

-

Rugged Design: Consistent with other Foxboro FBMs, the FBM211 features a robust, compact design with an extruded aluminum exterior for physical protection. This makes it suitable for deployment in harsh industrial environments (Class G3 per ISA Standard S71.04, referring to resistance to airborne contaminants).

-

Fieldbus Communication: The module communicates with the Field Control Processor (FCP) over the redundant 2 Mbps module Fieldbus. This ensures reliable and high-speed data transfer to the main controller. If one communication path fails, the module seamlessly continues communication over the active path.

-

Ease of Installation and Maintenance: The FBM211 mounts on standard Foxboro 200 Series baseplates (which can be DIN rail or rack-mounted) and uses dedicated termination assemblies and cables (e.g., P0916BT/BU for FBM-powered transmitters or P0916JT/PQ for externally powered transmitters). These termination assemblies simplify field wiring and allow for easy removal/replacement of the module without disturbing field wiring. For HART transmitters, a 200 ohm in-line resistor (P0902VY) must be added in series if an I/A Series Intelligent Transmitter with a Hand-Held Communicator is used.

Technical Specifications:

Applications:

The FOXBORO FBM211 is widely used in industries requiring precise and high-density current input measurements for critical process variables. Its robustness and accuracy make it ideal for:

- Process Industries (Chemical, Petrochemical, Oil & Gas, Pharmaceutical): Monitoring key variables like flow, pressure, level, and temperature (when using 4-20 mA transmitters) across numerous points in a plant. For example, a large chemical reactor might have dozens of temperature and pressure transmitters, all feeding 4-20 mA signals to multiple FBM211s for precise real-time monitoring and control.

- Power Generation: Acquiring signals from boiler instrumentation (e.g., water level, steam flow, flue gas oxygen), turbine monitoring, and balance-of-plant systems. The ability to handle many inputs on a single module is advantageous in complex power plant control systems.

- Water and Wastewater Treatment: Monitoring flow rates in pipes, levels in tanks, and various analytical parameters (pH, conductivity) from 4-20 mA output sensors throughout the treatment process. Its ability to work in potentially humid and corrosive environments is valuable here.

- Metals and Mining: Gathering data from various sensors involved in material handling, crushing, grinding, and smelting processes, where accurate measurements of flow, weight, and density are crucial.

- General Manufacturing: Used in diverse manufacturing settings for data acquisition from machinery, quality control sensors, and environmental monitoring equipment that utilize 4-20 mA outputs.

Related Products:

The FOXBORO FBM211 integrates seamlessly into the Foxboro I/A Series architecture and often works in conjunction with other modules:

- Foxboro FBM201 (P0914SQ): An 8-channel, 0-20mA isolated analog input module. While the FBM211 offers higher density (16 channels) and group isolation, the FBM201 provides channel-to-channel galvanic isolation, which might be preferred for certain critical or electrically noisy individual loops.

- Foxboro FBM202 (P0914TB / P0916AC): An 8-channel isolated thermocouple/mV input module, specialized for direct temperature measurements from thermocouples.

- Foxboro FBM205 (P0914XG): An 8-channel isolated analog voltage input module (0-5V, 0-10V). Used when field devices output voltage rather than current.

- Foxboro FBM214 / FBM214b (P0914TQ / P0922VT): HART Communication Input Modules (8-channel). While FBM211 can read 4-20 mA signals from HART devices, the FBM214 allows for accessing the digital data and diagnostic information embedded within the HART protocol.

- Foxboro Field Control Processors (FCPs – e.g., FCP270, FCP280): These are the “brains” of the DCS, receiving data from the FBM211, executing control strategies, and sending commands.

- Foxboro Fieldbus Communication Modules (FCMs – e.g., FCM10E, FCM10EF): These modules manage the high-speed 2 Mbps Fieldbus communication between the FBMs (including FBM211) and the FCPs.

- Foxboro Termination Assemblies (TAs) and Termination Cables: Essential physical connection components. The FBM211 typically uses specific 16-channel TAs (like P0916BT/BU or P0916JT/PQ) and corresponding 37-pin termination cables (Type 4 cables) to connect to field wiring. These TAs might provide loop power for the transmitters, or work with externally powered transmitters.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922