الوصف

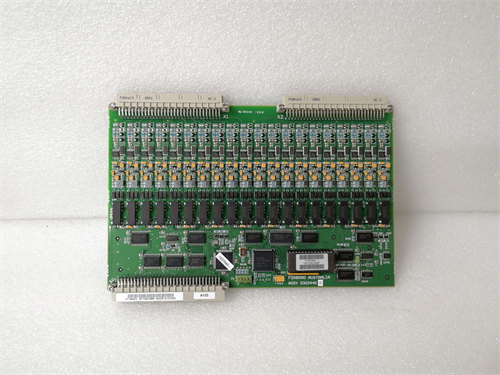

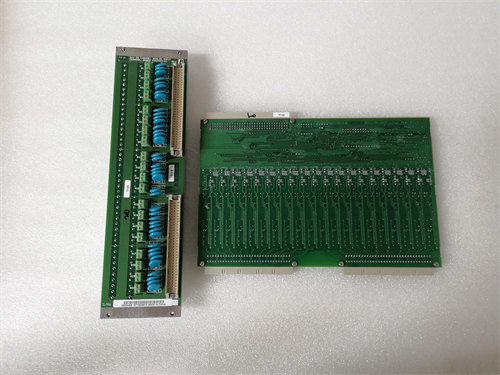

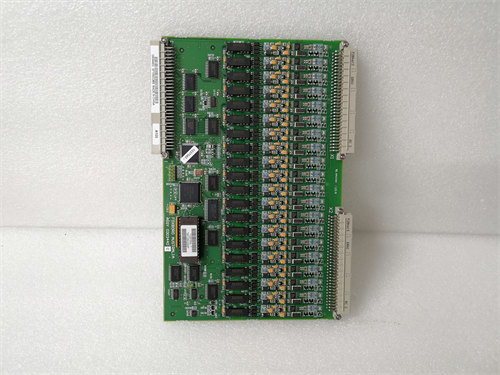

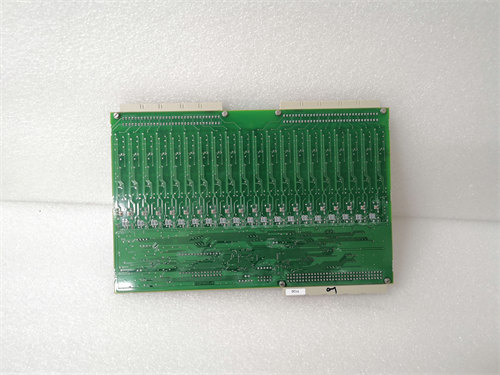

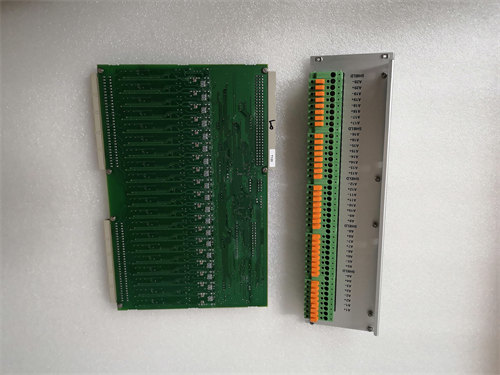

The product you’re referring to appears to be part of the FOXBORO I/A Series, which is a widely used Distributed Control System (DCS) in industrial automation. The part numbers 0399071D, 0303440C, and 0303443B are specific to Foxboro I/A Series modules, which integrate into control systems for monitoring and managing various process control applications.

I’ll break down the details based on the common product categories within the FOXBORO I/A Series DCS modules, as well as the general specifications associated with them.

Product Name:

FOXBORO I/A Series DCS Modules

- Model Numbers: 0399071D, 0303440C, 0303443B

These part numbers correspond to different types of modules in the Foxboro I/A Series DCS and PLC system. They are likely related to either I/O modules, communication modules, or controller modules.

Product Description:

The FOXBORO I/A Series is a widely used Distributed Control System (DCS) in industrial automation, particularly in process control industries like oil & gas, chemical, pharmaceutical, power generation, and water treatment. The modules within this system provide precise control, monitoring, and automation capabilities for complex industrial processes.

The FOXBORO I/A Series typically involves:

- Modular I/O modules for interfacing with field devices such as sensors, actuators, and other equipment.

- Controller modules that process real-time data from the field and execute control strategies.

- Communication modules that allow the system to integrate with external devices, other control systems, or a higher-level SCADA or MES system.

The modules you’ve listed may be specialized I/O modules or part of the backplane communication structure in the I/A Series system.

Product Parameters and Specifications:

FOXBORO I/A Series DCS Modules (General Specifications):

-

I/O Modules (Digital, Analog, and Mixed):

- Digital I/O: Supports discrete on/off signals like switches, relays, and contacts.

- Voltage Range: Typically 24V DC or 110V AC.

- Number of Channels: Varies, but commonly available in 8-channel or 16-channel configurations.

- Input/Output Types: May support sink or source configurations, or relay outputs.

- Analog I/O: Modules designed to interface with analog signals for continuous measurements like pressure, temperature, and flow.

- Input/Output Type: Typically 4-20 mA, 0-10V, or 0-5V.

- Resolution: 12-bit or 16-bit resolution, allowing high accuracy in measurements.

- Channels: Typically 4 to 8 channels per module.

- Mixed I/O Modules: Some modules support both analog and digital I/O to reduce space and complexity.

- Digital I/O: Supports discrete on/off signals like switches, relays, and contacts.

-

Controller Modules:

- Processor: Typically equipped with a high-performance embedded processor for real-time data processing.

- Redundancy: Supports redundant controllers for high availability and fault tolerance.

- Communication Protocols: Common protocols include Modbus, Ethernet/IP, Profibus, or Profinet for communication with field devices or higher-level control systems.

-

Communication Modules:

- Protocol Support: Includes various communication protocols such as Ethernet, Profibus, HART, Modbus, or proprietary Foxboro communication protocols.

- Ports: Includes both serial (RS-232/RS-485) and Ethernet ports, depending on module type.

- Data Rates: Typically supports 10/100/1000 Mbps Ethernet for high-speed data transfer.

-

Power Supply:

- Voltage Range: Typically operates within 24V DC for lower power consumption.

- Redundancy: Optional dual-redundant power supplies for greater system reliability.

- Power Consumption: Generally low to moderate power draw depending on the module type.

-

Environmental Specifications:

- Operating Temperature: Typically, modules can operate in temperatures ranging from 0°C to 60°C (32°F to 140°F). Extended-range models may be available for more extreme environments.

- Humidity: Modules usually operate in 5% to 95% non-condensing humidity.

-

Mounting and Integration:

- Rack-Mounting: These modules are generally designed to be mounted in a 19-inch rack or similar standard control cabinets.

- Redundant Configurations: Most modules can be part of a redundant setup for mission-critical applications.

-

Diagnostic and Monitoring:

- Status LEDs: LEDs for power, communication, and diagnostic status for quick troubleshooting.

- Self-Diagnostics: Built-in diagnostics to monitor module health and troubleshoot errors.

Specific Module Details (FOXBORO Modules)

0399071D:

- Likely to be a communication module or controller in the I/A Series DCS setup.

- Supports networking for integration with higher-level control systems or external devices.

- Specific details would depend on the exact module configuration and associated firmware version.

0303440C & 0303443B:

- These may be I/O modules or specialized control modules designed for specific tasks within the DCS system.

- These modules are often used for precise control and signal conversion between field devices and the central processor of the DCS.

- The differences between these two models might lie in channel count, type of inputs/outputs, or communication protocols supported.

Common Applications:

- Oil & Gas: Used for downstream refining, upstream drilling, and gas processing applications.

- Chemical Processing: Controls chemical reactors, mixing, and separation processes in continuous production systems.

- Power Generation: Used in the monitoring and control of power plants for safe and efficient energy production.

- Water Treatment: Ensures proper treatment processes in municipal or industrial water treatment plants.

Conclusion:

The FOXBORO I/A Series DCS modules are highly reliable and flexible components used in a variety of industrial process control environments. The modules with part numbers 0399071D, 0303440C, and 0303443B are likely related to specific I/O or communication modules within this series, offering high reliability, real-time control, and integration with both field devices and central control systems.

If you need more specific details or have a question about a specific model (e.g., the type of I/O, communication capabilities, or exact application), let me know, and I can look into it further!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922